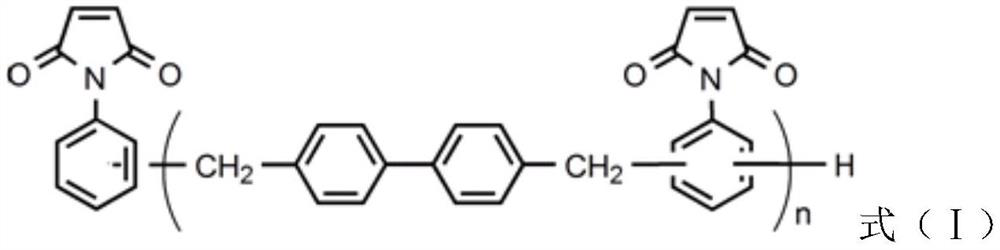

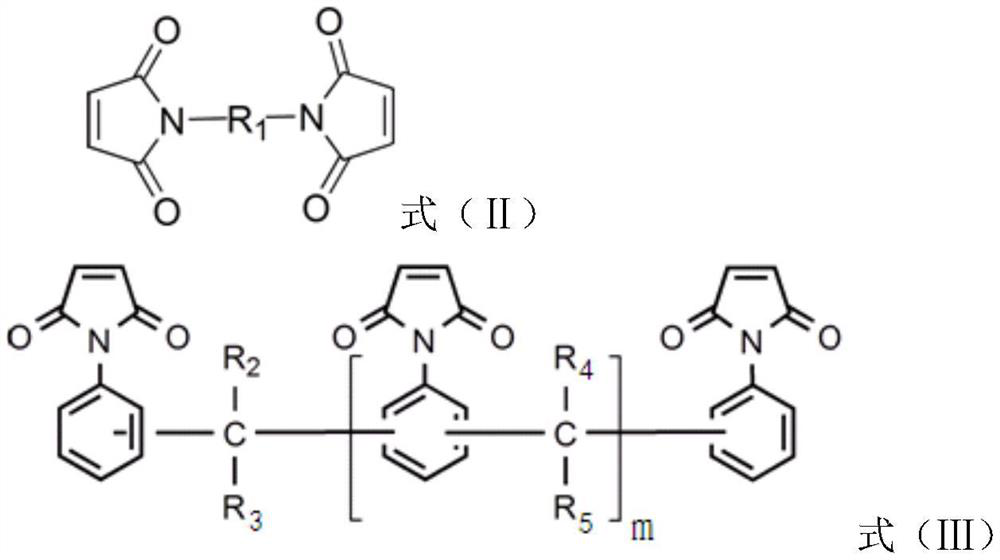

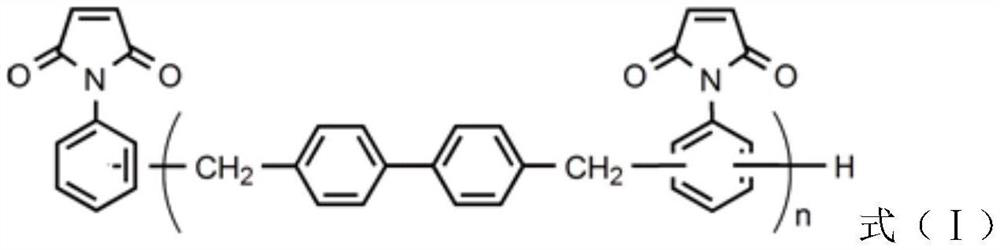

Maleimide resin composition and application thereof

A technology of maleimide resin and bismaleimide, applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., can solve the problem of sacrificing the heat resistance of maleimide resin, Increased dielectric constant and dielectric loss, affecting heat resistance or dielectric properties of maleimide resin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation of the maleimide resin composition in the present invention can be appropriately selected from known methods, for example, by uniformly mixing the components or prepolymerizing them. As one of the preferred preparation methods, the steps are as follows: heat the maleimide resin, crosslinking agent, and initiator to 80-180°C, keep it under stirring for 10-300 minutes, and then add the flame retardant after cooling to room temperature , a filler to obtain a maleimide resin composition. If necessary, an inert solvent is added to the composition to facilitate processing. The solvent used may include but not limited to butanone, acetone, N,N-dimethylformamide, N,N-dimethylacetamide, N-methyl Pyrrolidone, cyclohexanone, toluene, xylene, each solvent can be used alone or in combination.

[0039] The aforementioned maleimide resin composition can be processed into various electronic product components including prepregs, copper-clad laminates or printed circuit...

Embodiment 1

[0046] Heat 30 parts by mass of TAIC to 130°C in a three-necked flask, then add 20 parts by mass of BMI-1, 50 parts by mass of BMI-2, and 1 part by mass of DCP, stir at this temperature for 15 minutes to make the mixture uniform, and then heat up to 160°C, react at this temperature for 30min. After cooling to room temperature, add an appropriate amount of N,N-dimethylformamide and butanone, stir evenly, add 5 parts by mass of OP-935 and 170 parts by mass of FB-3Y to prepare a composition glue; use 2116 glass fiber The cloth is soaked in the above glue, and the solvent is dried in an oven at 170°C to make a prepreg; the prepreg is laminated on both sides with a standard copper foil with a thickness of 1 oz, and it is vacuum-cured in a press for 2 hours at a curing temperature of 240°C. into a copper clad laminate.

Embodiment 2

[0048] 50 parts by mass of BMI-3 was used to replace 50 parts by mass of BMI-2, and the others were the same as in Example 1 to prepare a copper-clad laminate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com