UV-cured hard coating and preparation method thereof

A technology of hard coating and diallyl bisphenol, which is applied in the field of UV curing hard coating and its preparation, can solve the problems of cumbersome preparation process and many side reactions of polyurethane acrylate, and achieve simple preparation method and high reaction rate The effect of low temperature and solving the complicated preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] On the other hand, the present invention also provides a kind of preparation method of cured hard coating, comprises the steps:

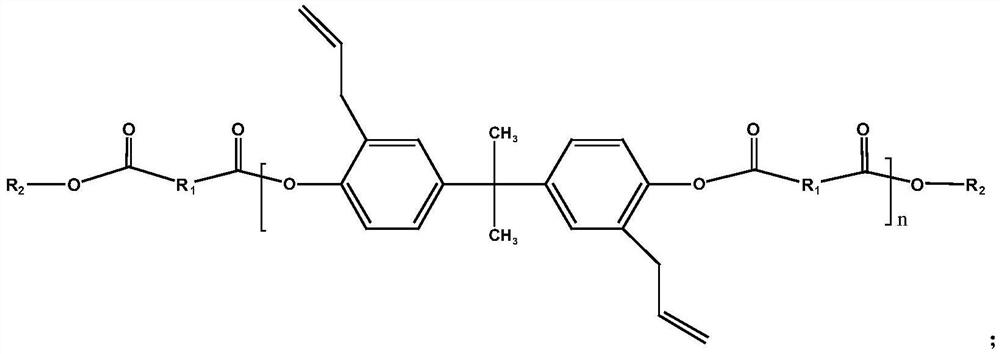

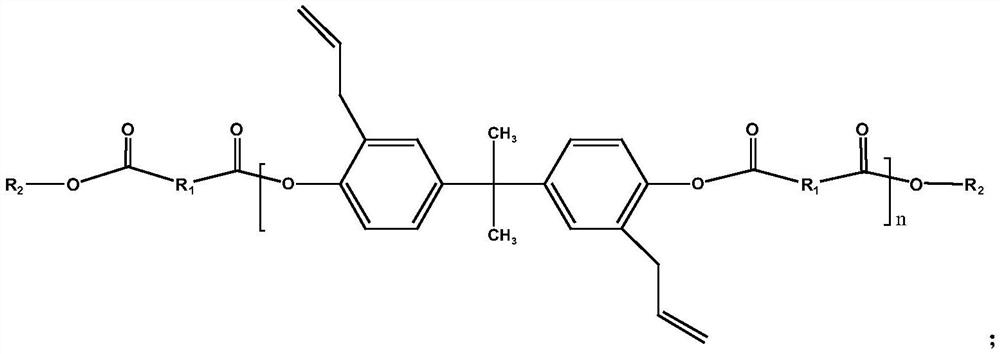

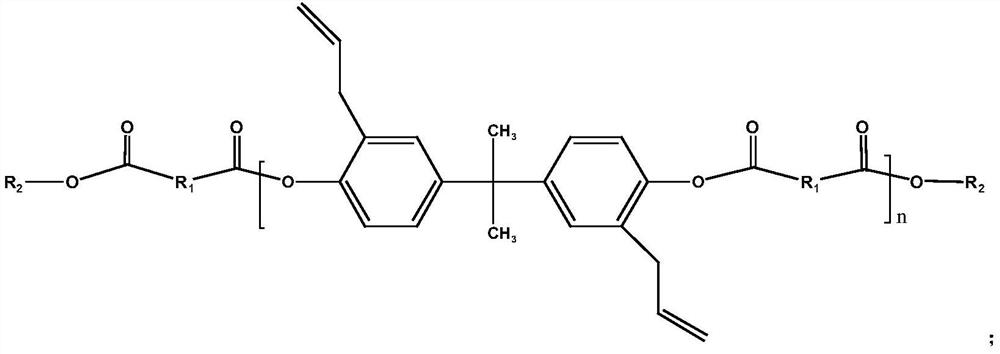

[0046] S1 Diallyl bisphenol A monomer and diacid chloride monomer synthesize diallyl bisphenol A-diacid chloride copolyester;

[0047] S2 diallyl bisphenol A-diacyl chloride copolyester is mixed with a photoinitiator to obtain a UV curing hard coating solution;

[0048] S3 UV curable hard coating solution is cured by UV light to obtain UV curable hard coating.

[0049] In a specific embodiment, step S1 specifically includes, for example:

[0050] S11 Add solvent A and acid binding agent to diallyl bisphenol A monomer to form a solution of diallyl bisphenol A;

[0051] S12 Dissolve the diacid chloride monomer in solvent A, and add it to the solution of diallyl bisphenol A under the protection of nitrogen to carry out condensation reaction, and then add an end-capping agent to carry out end-capping reaction;

[0052] S13 is centrifuged to re...

Embodiment 1

[0064] A UV curing hard coating, the preparation method is as follows:

[0065] (1) Preparation of diallyl bisphenol A-isophthaloyl chloride copolyester

[0066] Weigh 15.42g (0.05mol) of diallyl bisphenol A in a 250mL two-necked flask equipped with a constant pressure funnel and a magnetic stirrer, then add 40mL of tetrahydrofuran to dissolve it, then add 12.14g (0.12mol) ) triethylamine; 12.18g (0.06mol) of isophthaloyl chloride was added to a constant pressure funnel, and 12mL of tetrahydrofuran was added to dilute it, and then the contents of the two-necked flask were mixed uniformly and placed in a water bath at 25°C in the pot. Then slowly drop the isophthaloyl dichloride solution in the constant pressure funnel into the two-necked flask for about 1 hour; after 2.5 hours of reaction, raise the temperature of the system to 45°C, continue the reaction at 45°C for 4 hours, and then add 2.86g (0.022mol) of hydroxyethyl methacrylate and continue to react for 4h. After the ...

Embodiment 2

[0070] A UV curing hard coating, the preparation method is as follows:

[0071] (1) Preparation of diallyl bisphenol A-fumaryl chloride copolyester

[0072] Weigh 15.42g (0.05mol) of diallyl bisphenol A in a 250mL two-necked flask equipped with a constant pressure funnel and a magnetic stirrer, then add 40mL of tetrahydrofuran to dissolve it, then add 12.14g (0.12mol) ) triethylamine; 9.18g (0.06mol) of fumaryl chloride was added to the constant pressure funnel, and 12mL of tetrahydrofuran was added to dilute it, then the contents of the two-necked flask were mixed uniformly and placed in a water bath at 25°C . Then slowly drop the fumaryl chloride solution in the constant pressure funnel into the two-necked flask for about 1 hour; after 2.5 hours of reaction, raise the temperature of the system to 45°C, continue the reaction at 45°C for 4 hours, and then add 2.86g (0.022mol) of hydroxyethyl methacrylate and continued to react for 4h. After the reaction was completed, the t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap