Magnetic nanoparticle-glycosyl transferase-amorphous metal organic framework composite catalytic material as well as preparation method and application thereof

A technology of metal-organic frameworks and glycosyltransferases, applied in biochemical equipment and methods, transferases, immobilized on or in inorganic carriers, etc., can solve the problems of enzymes being easily soluble in water, high catalytic costs, and affecting activity, etc. problems, to achieve the effect of low raw material cost, high catalytic activity, and mild synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Preparation of magnetic nanoparticles (MNPs):

[0060] FeCl 3 solution (10mL, 5mM) with FeCl 2 Put the solution (10mL, 10mM) into a double-necked flask, add a magnet, pass in nitrogen, and discharge oxygen. Place it in a water bath constant temperature magnetic stirrer at 75°C, heat and stir the reaction at a speed of 300rpm, and cool to room temperature after 1h of reaction , add ammonia water (10%) to the obtained reaction solution, the volume ratio of ammonia water to the reaction solution is 1:3, place it in a water bath constant temperature magnetic stirrer, heat and stir the reaction at 75°C, the rotation speed is 200rpm, and react for 1h; Cool to room temperature, recover magnetic nanoparticles (MNPs) under magnetic field conditions, add water after drying to prepare a certain concentration of MNP solution.

Embodiment 2

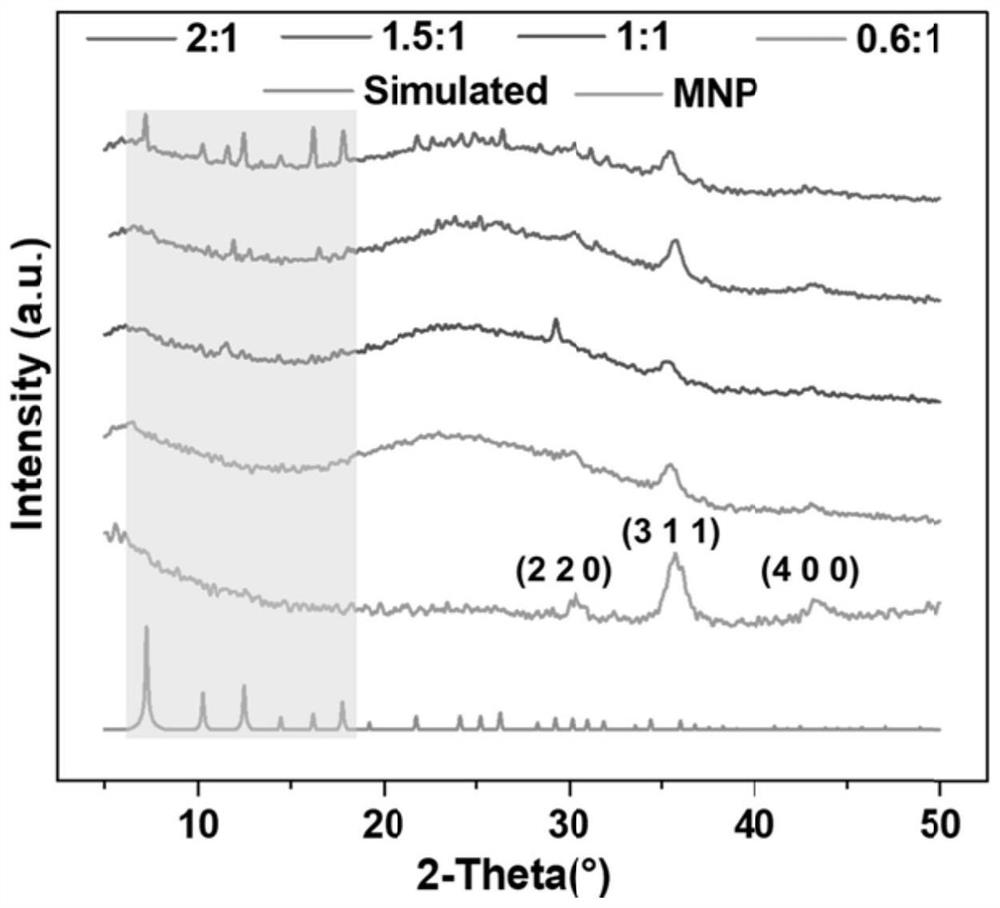

[0062] Preparation of MNPs-HS2@aZIF-90:

[0063] Get the MNPs solution that 0.6mL concentration is 1mg / mL prepared in Example 1, stir and mix and add to 1mL Zn(NO 3 ) 2 ·6H 2O (40mM) and 1mL glycosyltransferase pmHS2 (0.3mg / mL) mixed solution, then add 1mL 2-imidazole-carboxaldehyde (HICA, dissolve at high temperature, 40mM) solution and add ultrapure water to make up to 4mL. React at 37° C. and 500 rpm for 15 hours. After the reaction, centrifuge at 8,000 rpm for 4 minutes to recover the precipitate. Then, it was washed three times with ultrapure water to remove the glycosyltransferase not wrapped by the aZIF-90 material, and the magnetic nanoparticle-glycosyltransferase-amorphous metal-organic framework composite catalytic material was obtained.

Embodiment 3

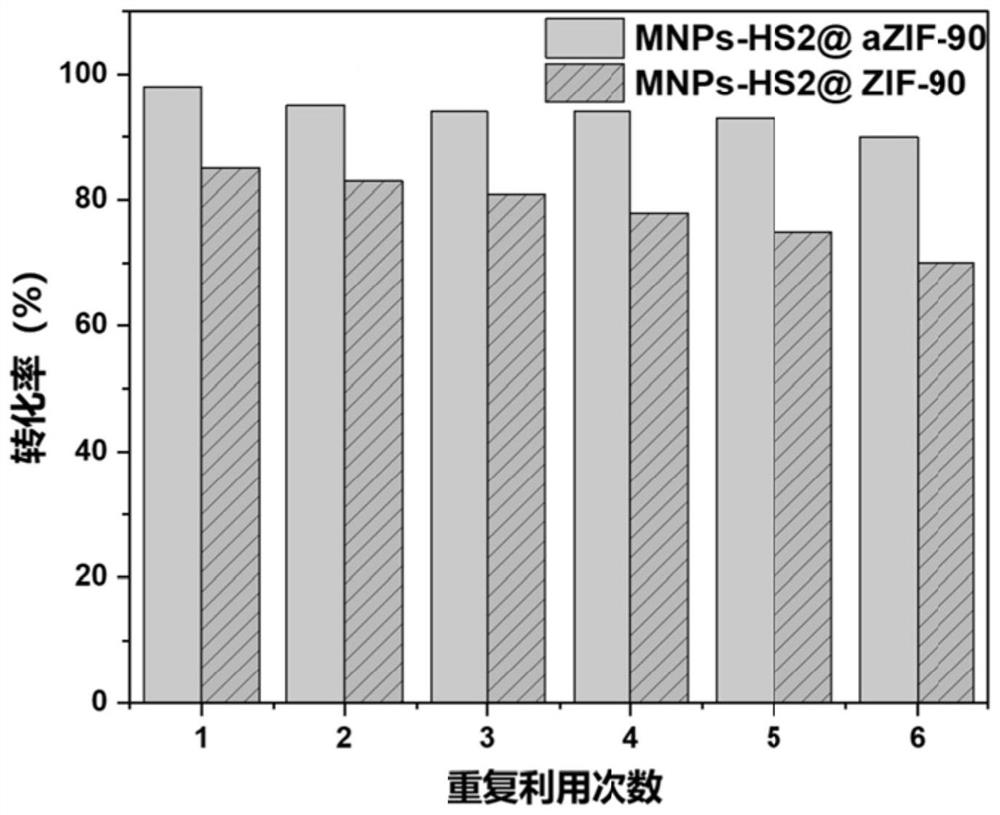

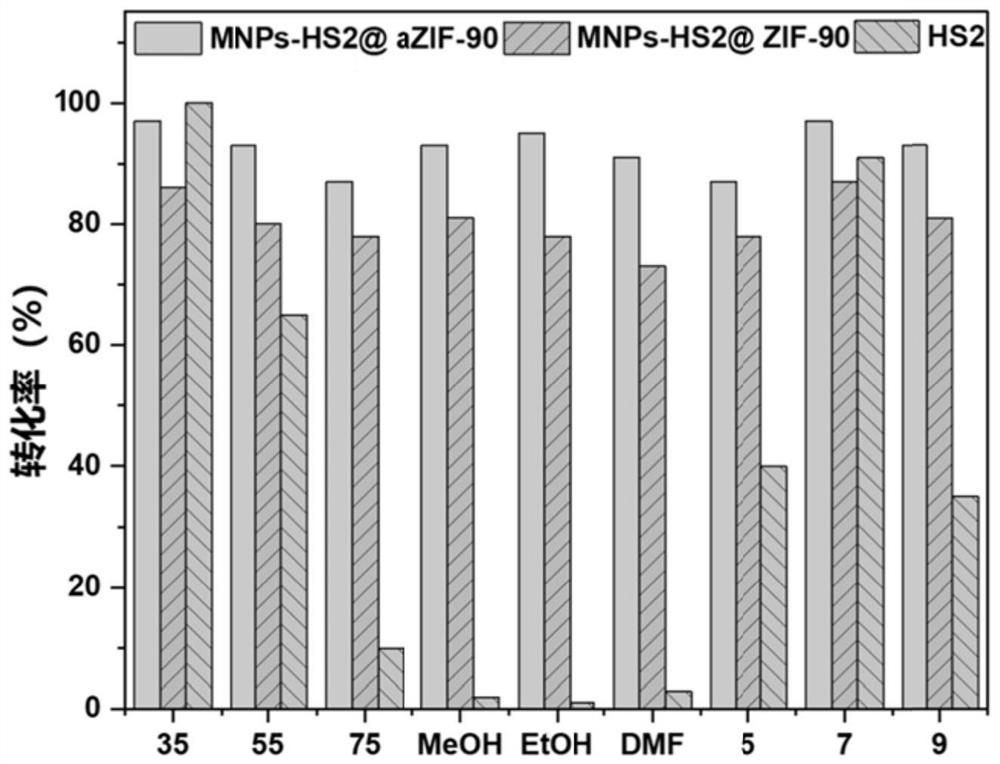

[0065] The preparation method of MNPs-HS2@aZIF-90 catalyzing the glycosylation of monosaccharides to generate heparin disaccharides:

[0066] In Tris-HCl buffer (50mM pH 7.4), add uridine diphosphate-N-acetylglucosamine (final concentration 10mM), p-nitrophenyl-β-D-glucuronic acid (final concentration 10mM), magnesium chloride ( Final concentration 10mM) was shaken and mixed in a water bath at 37°C, the speed was 150rpm, and the time was 5min. After mixing, add uridine diphosphate-N-acetylglucosamine and p-nitrophenyl-β-D-glucuronic acid 5% of the MNPs-HS2@aZIF-90 composite catalyst prepared in Example 2 was shaken in a water bath at 37° C. at 150 rpm, and the reaction was completed after 12 hours of sufficient reaction. The product was centrifuged at 10,000 rpm for 5 minutes, the upper layer oil was taken, and the remaining solution was subjected to magnetic adsorption to collect the composite catalytic material, washed for reuse, and the supernatant was taken for TLC separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com