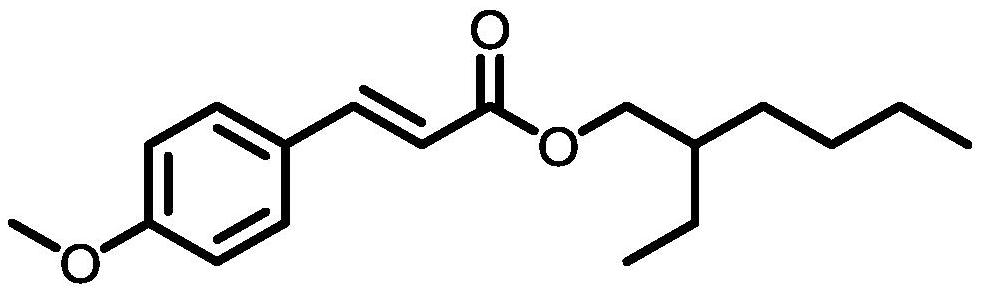

Solid superacid catalyst and method for preparing iso-octyl p-methoxycinnamate by using same

A technology of methoxycinnamic acid and solid superacid, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds. It can solve the problems of complicated synthesis methods and waste water generation, and achieve easy recycling and increase Effects of specific surface area and enriched mesoporous structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] Specifically, a preparation method of isooctyl p-methoxycinnamate comprises the following steps:

[0033] Under normal pressure, add a certain amount of p-methoxybenzoic acid, isooctyl alcohol, alkane compound and catalyst X-SO 4 2- / Cr 2 o 3 -SiO 2 , heat up to a certain temperature for heat preservation reaction, reflux and water separation, after the reaction, remove the catalyst X-SO by filtration 4 2- / Cr 2 o 3 -SiO 2 , successively add saturated sodium carbonate solution and distilled water to wash until the solution becomes neutral, remove the solvent and excess isooctyl alcohol, and rectify to obtain isooctyl p-methoxycinnamate.

[0034] Wherein, the molar ratio of p-methoxybenzoic acid to isooctyl alcohol is 1.0-4.0:1, for example including but not limited to 1:1, 1.5:1, 2:1, 2.5:1, 3:1, 3.5 :1,4:1, preferably 1.5-2.0:1; the alkane solvent is selected from at least any one of n-pentane, isopentane, n-hexane, cyclohexane, dodecane, preferably cyclohexan...

Embodiment 1

[0052] 1) Preparation of X-SO 4 2 - / Cr 2 o 3 -SiO 2 catalyst:

[0053] Add 0.35g graphene (0.07wt%) to 500g deionized water, add 80% sulfuric acid to adjust pH to 3, then add 8.75g (25 times of graphene quality) chromium picolinate (with Cr 2 o 3 In terms of), add 4.375g ethyl orthosilicate (as SiO 2 In terms of), the amount added is the mass of chromium (in terms of Cr 2 o 350wt% of total), the temperature was adjusted to 60°C, and the hydrolysis reaction was carried out for 3 hours; then the precipitate obtained in the above hydrolysis reaction was filtered to obtain a catalyst precursor, which was dried and immersed in 120mL of 0.7mol / L sulfuric acid for 1.8h (solid-liquid Ratio is 10mL sulfuric acid / 1g solid), after centrifugal drying, equal volume is placed in 4wt% Ti(NO 3 ) 4 solution, soaked for 4 hours; finally, the impregnated solid was filtered and washed, then placed in an air roaster for roasting, the roasting condition was 700 ° C, and the time was 8 hou...

Embodiment 2

[0057] 1) Preparation of X-SO 4 2 - / Cr 2 o 3 -SiO 2 catalyst:

[0058] Add 0.35g graphene (0.07wt%) to 500g deionized water, add 80% sulfuric acid to adjust pH to 3, then add 8.75g (25 times of graphene quality) chromium picolinate (with Cr 2 o 3 In terms of), add 4.375g ethyl orthosilicate (as SiO 2 In terms of), the amount added is the mass of chromium (in terms of Cr 2 o 3 50wt% of total), the temperature was adjusted to 60°C, and the hydrolysis reaction was carried out for 3 hours; then the precipitate obtained in the above hydrolysis reaction was filtered to obtain a catalyst precursor, which was dried and immersed in 120mL of 0.7mol / L sulfuric acid for 1.8h (solid-liquid Ratio is 10mL sulfuric acid / 1g solid), after centrifugal drying, equal volume is placed in 4wt% Ti(NO 3 ) 4 solution, soaked for 4 hours; finally, the impregnated solid was filtered and washed, then placed in an air roaster for roasting, the roasting condition was 700 ° C, and the time was 8 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com