Micron-sized porous sodium ferrous sulfate/carbon composite positive electrode material and sodium ion battery or sodium battery prepared from same

A technology for sodium ferrous sulfate and sodium ion batteries, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as damage to battery long-term cycle stability, structural agglomeration, and reduce the compaction density of positive electrodes, so as to achieve abundant raw material reserves , enhance electronic conductivity, improve the effect of tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

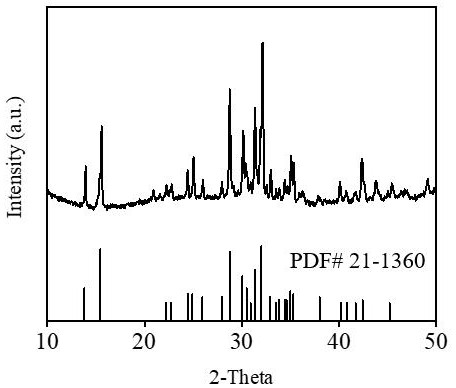

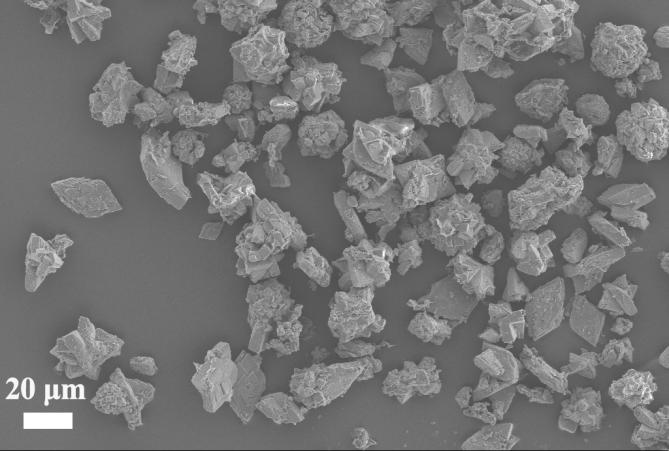

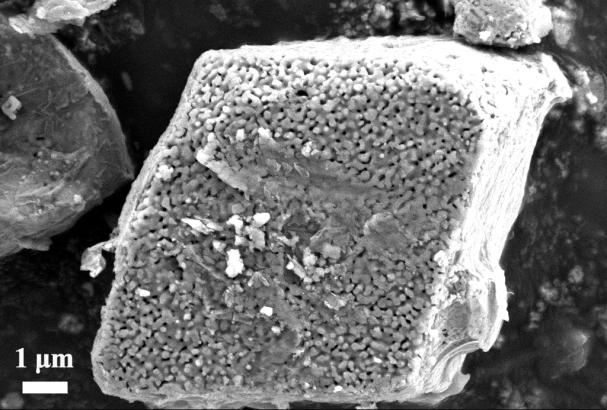

[0046] The synthesis steps of the micron-scale porous sodium ferrous sulfate / carbon composite cathode material used in the present invention are as follows: Weigh 0.02g graphene oxide dry powder and disperse it in 20mL deionized water (1mg / mL), then add 10mL ethylene glycol, and stir for 1h , sonicated for 15 minutes to form a graphene oxide dispersion. Another weighed 1.112g ferrous sulfate heptahydrate (FeSO 4 ·7H 2 O), 0.5682g anhydrous sodium sulfate (Na 2 SO 4 ), 0.2 g of citric acid monohydrate, and 0.02 g of ascorbic acid were dissolved in the above graphene oxide dispersion, and stirred at room temperature (25° C.) for 1 h. Take 40 mL of isopropanol and add it dropwise to the above solution to obtain a cloudy suspension. After the dropwise addition was completed, stir for another 1 h. The above turbid suspension was centrifuged (centrifugation speed was 8500r / min, centrifugation time was 3min), the obtained solid was frozen by liquid nitrogen, and then freeze-drie...

Embodiment 2

[0050] The preparation of the micron-scale porous sodium ferrous sulfate / carbon composite cathode material in this example is the same as that in Example 1.

[0051] The prepared micron-scale porous sodium ferrous sulfate / carbon composite positive electrode material is used as the positive electrode active material, commercial hard carbon is used as the negative electrode active material, and the positive electrode active material is mixed with acetylene black and polyvinylidene fluoride in a mass ratio of 70:20:10 , using 1-methyl-2-pyrrolidone as a dispersant; the negative electrode active material is mixed with acetylene black and sodium carboxymethylcellulose (CMC) in a mass ratio of 80:10:10, and deionized water is used as a dispersant; the above The mixture was evenly mixed to form a slurry, which was coated on the aluminum foil and the copper foil respectively, and dried and cut in vacuum at 120° C. to obtain the corresponding positive electrode sheet and negative electr...

Embodiment 3

[0053] The preparation of the micron-scale porous sodium ferrous sulfate / carbon composite cathode material in this example is the same as that in Example 1.

[0054] The prepared micron-scale porous sodium ferrous sulfate / carbon composite positive electrode material is used as the positive electrode active material, and the ferrous sulfide / carbon composite material is used as the negative electrode active material. Mass ratio mixing, using 1-methyl-2-pyrrolidone as a dispersant; negative electrode active material, acetylene black, and sodium carboxymethylcellulose (CMC) in a mass ratio of 80:10:10, using deionized water as a dispersant ; Mix the above mixture evenly to form a slurry and apply it on the aluminum foil and copper foil respectively, dry and cut in vacuum at 120°C to obtain the corresponding positive electrode sheet and negative electrode sheet. The positive and negative electrodes were separated by glass fiber membrane (Whatman GF / D), using 1M NaClO 4 Dissolved i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com