System and method for treating sludge and organic waste by cooperating with waste heat of cement kiln

A technology for organic waste and waste heat treatment, which is applied in pyrolysis treatment of sludge, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. It can solve the problem of low resource utilization and difficult to find Construction sites, incomplete utilization of resources, etc., to achieve the effect of improving the effect of pyrolysis and gasification, simplifying pollution control problems, and reducing primary energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

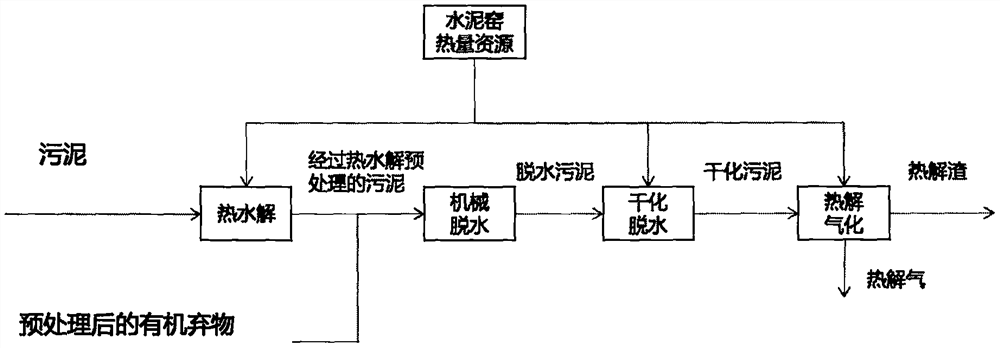

[0066] A method for cooperating with cement kiln waste heat to treat sludge and organic waste comprises the following steps:

[0067] Step S1. Waste heat recovery, the cement kiln waste heat utilization device provides the waste heat resources of the cement kiln, and the waste heat resources are used as heat sources for sludge thermal hydrolysis pretreatment, pyrolysis gasification device, and dehydration and drying device for sludge thermal hydrolysis Pretreatment, pyrolysis and gasification device and dehydration and drying device; the heat source of the pyrolysis and gasification device is the tertiary air heat resource, the heat source of the sludge thermal hydrolysis pretreatment device is waste heat boiler steam, and the heat source of the dehydration and drying device is Cement kiln flue gas;

[0068] Step S2. Thermal hydrolysis pretreatment. The sludge thermal hydrolysis pretreatment device performs thermal hydrolysis pretreatment on the collected sludge. The moisture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com