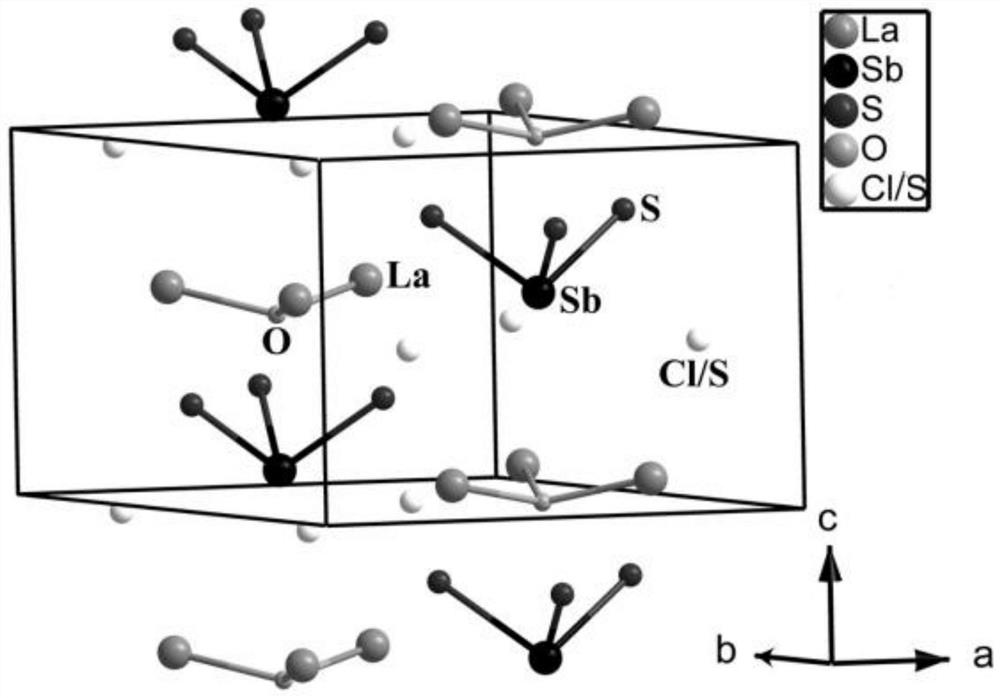

Polar crystal La3SbS4OCl2 and preparation method thereof

A polar crystal and crystal technology, which is applied in the field of polar crystal La3SbS4OCl2 and its preparation, can solve the problem of insufficient laser damage threshold of polar crystals, and can improve the laser damage threshold, enhance ionicity, and increase spontaneous polarization intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0021] Polar crystal La in Example 1-5 of the present invention 3 Sb 4 OCl 2 The composition and dosage of synthetic raw materials are shown in Table 1.

[0022] The consumption of each raw material in table 1 embodiment 1-5

[0023] Ingredients Example 1 Example 2 Example 3 Example 4 Example 5 Elemental lanthanum / g 0.2 0.23 0.1751 0.1511 0.1300 Lanthanum trichloride / g 0.1009 0.1160 0.0883 0.0762 0.0656 Elemental antimony / g 0.0250 0.0288 0.0219 0.0189 0.0163 Antimony trioxide / g 0.0600 0.0670 0.0525 0.0453 0.0390 Elemental sulfur / g 0.0791 0.0910 0.0693 0.0598 0.0515

[0024] Specifically, polar crystal La in embodiment 1-5 3 Sb 4 OCl 2 The preparation method is as follows:

[0025] (1) Weigh elemental lanthanum, lanthanum trichloride, elemental antimony, antimony trioxide, and elemental sulfur in a glove box full of nitrogen, and the specific amounts are shown in Table 1; the glove box is made of M....

Embodiment 6

[0031] Compared with Example 3, the difference is only that there is a difference in the parameters in each step; specifically as follows: the volume fraction of step (1) in Example 3 is replaced by 99.99% nitrogen by volume fraction as 99.99% argon, and The water content and the oxygen content in the water jacket box are all controlled to be 0.08ppm; The vacuum degree of step (3) in the embodiment 3 is 10 -2 Pa is replaced by 0.8×10 -2 Pa, and the hydrogen-oxygen welding machine is replaced by an acetylene welding machine; the heating rate of the step (4) tubular resistance furnace in embodiment 3 is replaced by 18 °C / h at 20 °C / h, and the tubular resistance furnace is heated to 950 °C was replaced by heating up to 980 °C, and the total reaction time was replaced by 110 h from 117 h; the cooling rate in step (5) in Example 3 was replaced by 2 °C / h from 2.5 °C / h.

[0032] The remaining steps and condition parameters are consistent with those in Example 3, and polar crystal La...

Embodiment 7

[0034] Compared with Example 3, the difference is only that there is a difference in the parameters in each step; specifically as follows: the volume fraction of step (1) in Example 3 is 99.99% nitrogen replaced by 99.99% helium by volume fraction, and The water content and the oxygen content in the water jacket box are all controlled to be 0.06ppm; The vacuum degree of step (3) among the embodiment 3 is 10 -2 Pa is replaced by 0.7×10 -2 Pa, and the oxyhydrogen welding machine is replaced by an acetylene welding machine; the heating rate of the step (4) tubular resistance furnace in embodiment 3 is replaced by 22 °C / h for 22 °C / h, and the tubular resistance furnace is heated to 950 °C was replaced by raising the temperature to 930 °C, and the total reaction time was replaced by 121 h from 117 h; the cooling rate in step (5) in Example 3 was replaced by 3 °C / h from 2.5 °C / h.

[0035] The remaining steps and condition parameters are consistent with those in Example 3, and polar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com