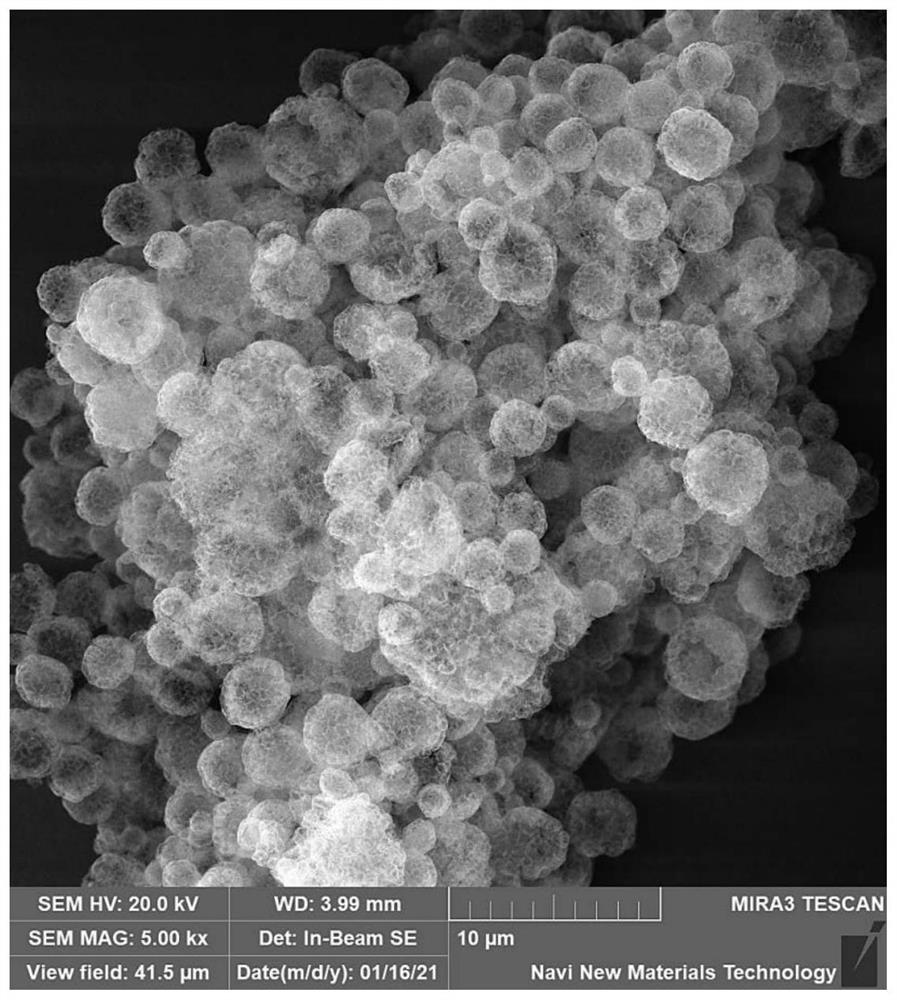

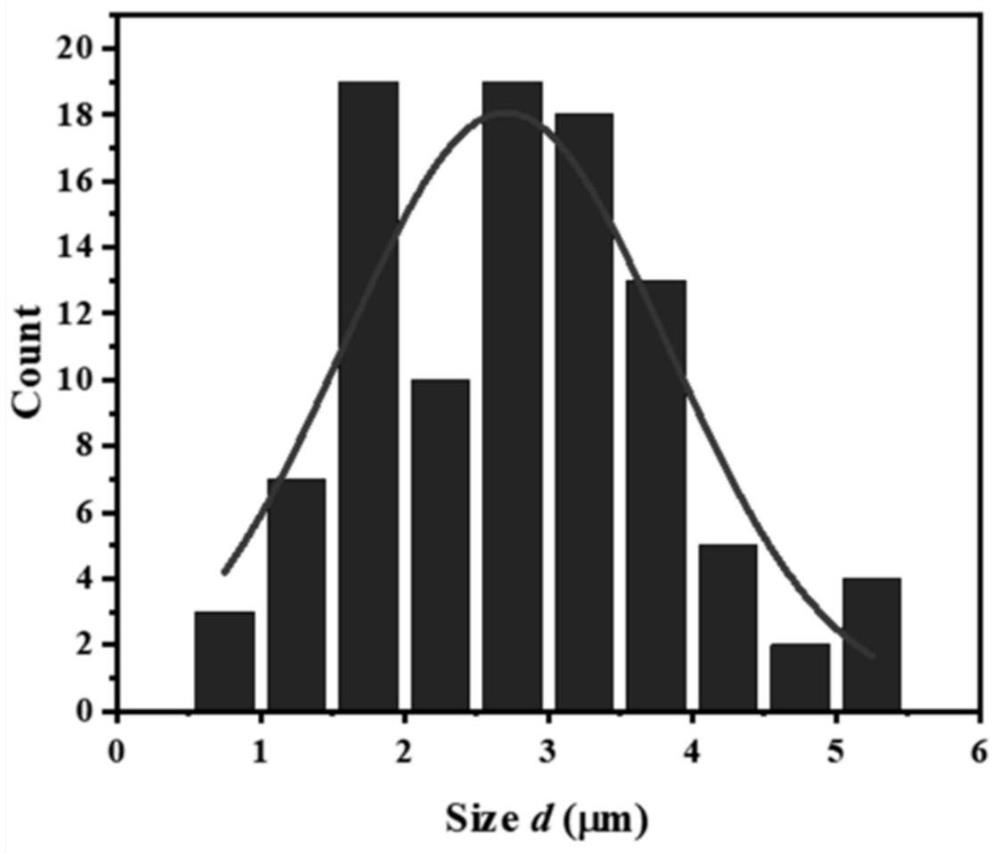

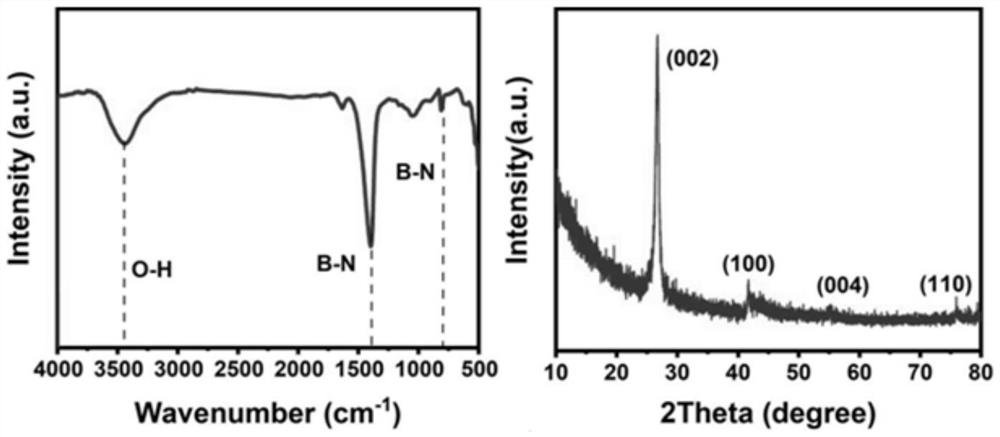

High-oil-absorption whitening hexagonal boron nitride porous microsphere for cosmetics

A technology of hexagonal boron nitride and porous microspheres, which is applied in the direction of cosmetics, cosmetic preparations, nitrogen compounds, etc., can solve the problems of low oil absorption and application limitations, and achieve large oil absorption, convenient post-treatment and purification, and excellent preparation process and device simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of hexagonal boron nitride porous microspheres, comprising the steps of:

[0028] Add 0.02 mol of boric acid, 0.015 mol of 2-methylimidazole and 0.07 mol of sodium chloride into a beaker containing 130 mL of deionized water, heat and stir, the heater temperature is set to 90°C, and the stirring rate is 450 r / min, After obtaining a completely clear and transparent solution, stop heating and stirring, and then spray dry the obtained clear and transparent solution through a spray dryer, set the air inlet temperature to 180°C, and the feed flow rate to 800mL / min to prepare a white precursor powder;

[0029] Weigh 4g of the obtained white precursor powder, lay it flat on a rectangular corundum porcelain boat, and pass ammonia gas into a tube furnace for high-temperature reaction. The heating rate is 10°C / min, the reaction temperature is 1000°C, and the reaction time is 3h. Cool naturally after reaction, obtain the hexagonal boron nitride microsphere pow...

Embodiment 2、3、4

[0035] Change the amount of 2-methylimidazole in Example 1 to 0.02mol, 0.005mol, and 0.0025mol, and the other operations are the same as in Example 1.

Embodiment 5

[0037] Change the high-temperature reaction temperature into 1200° C. in Example 1, and other operations are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com