Micron-sized lamellar Si/SiO2 composite material as well as preparation method and application of micron-sized lamellar Si/SiO2 composite material

A composite material, micron-scale technology, applied in the direction of active material electrodes, structural parts, electrical components, etc., can solve the problems of expensive raw materials, equipment, high overall product cost, unfavorable industrial production, etc., to achieve simple equipment, strong repeatability, Ease of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 1.0 g of kaolin, ammonium chloride and aluminum powder and mix, add 5 mL of absolute ethanol, grind for 0.1 hour, and vacuum dry to obtain the precursor. The precursor was calcined under argon at 600°C for 1 hour, then pickled, washed with water, and dried in vacuum; the final product was obtained after secondary acid treatment with hydrofluoric acid for 0.1 hour, washed, and dried.

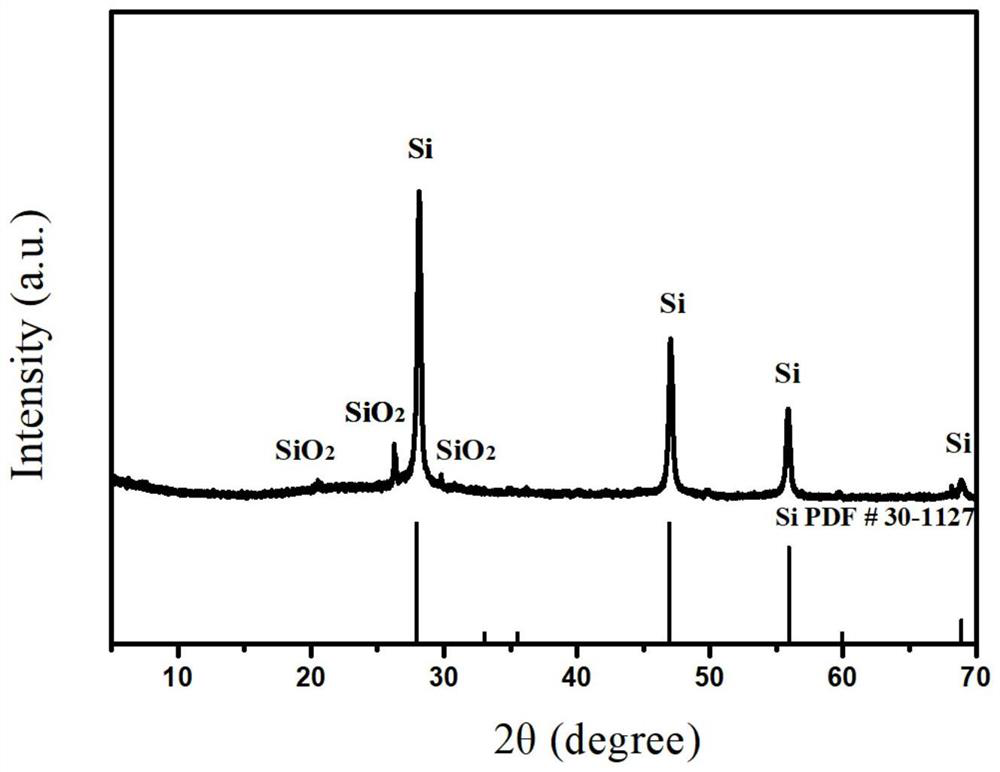

[0031] see figure 1 , figure 1 Micron-scale lamellar Si / SiO prepared for the present invention 2 The XRD pattern of the composite material, from which the phase composition can be determined as Si and SiO 2 , the product has high purity and no other impurity phases.

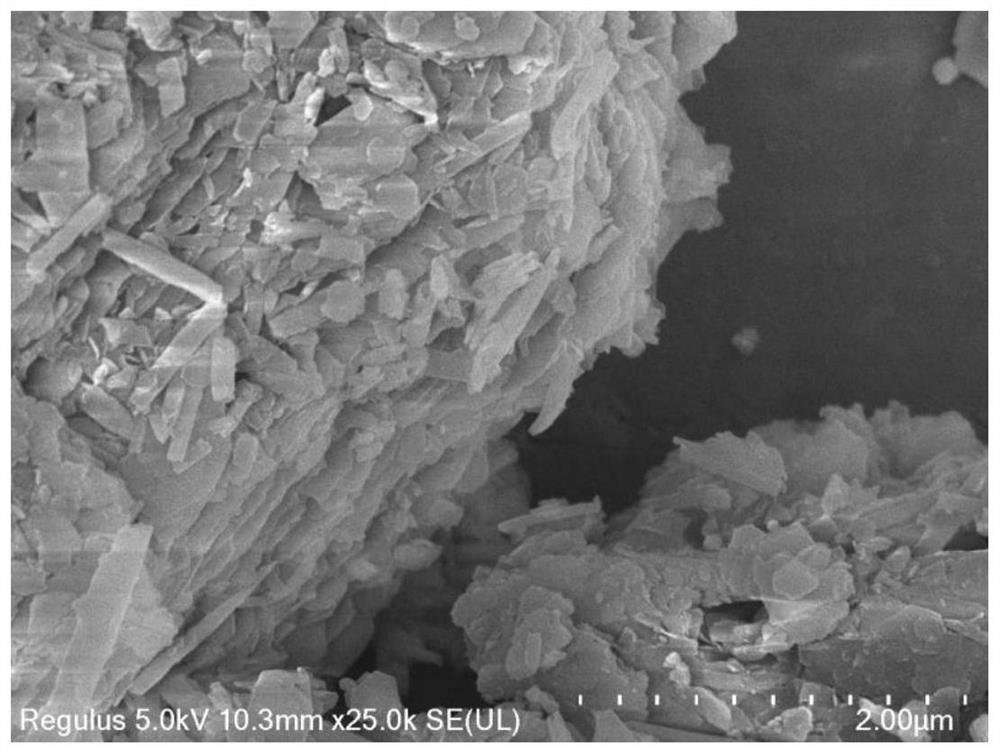

[0032] see figure 2 , figure 2 Be the scanning electron micrograph of embodiment 1 product, wherein the Si / SiO that makes 2 The morphology of the composite material is distinct, in the form of micron-scale flakes, with a product size of 2 μm and a thickness of 100 nm, and particles scattered on the surface that ...

Embodiment 2

[0036] Weigh 1.0 g, 1.0 g, and 3.0 g of kaolin, ammonium chloride, and aluminum powder, mix them, add 10 mL of absolute ethanol, grind for 0.5 hours, and vacuum dry to obtain a precursor. The precursor was calcined at 700°C under nitrogen for 1 hour, pickled, washed with water, and dried in vacuum; the final product was obtained after secondary acid treatment with hydrofluoric acid for 1 hour, washed, and dried.

Embodiment 3

[0038] Weigh 1.0 g, 3.0 g, and 1.0 g of kaolin, ammonium chloride, and aluminum powder, mix them, add 5 mL of absolute ethanol, grind for 0.3 hours, and vacuum dry to obtain a precursor. The precursor was calcined at 500°C under argon for 0.5 hours, pickled, washed with water, and dried in vacuum; the final product was obtained after secondary acid treatment with hydrofluoric acid for 0.3 hours, washed, and dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com