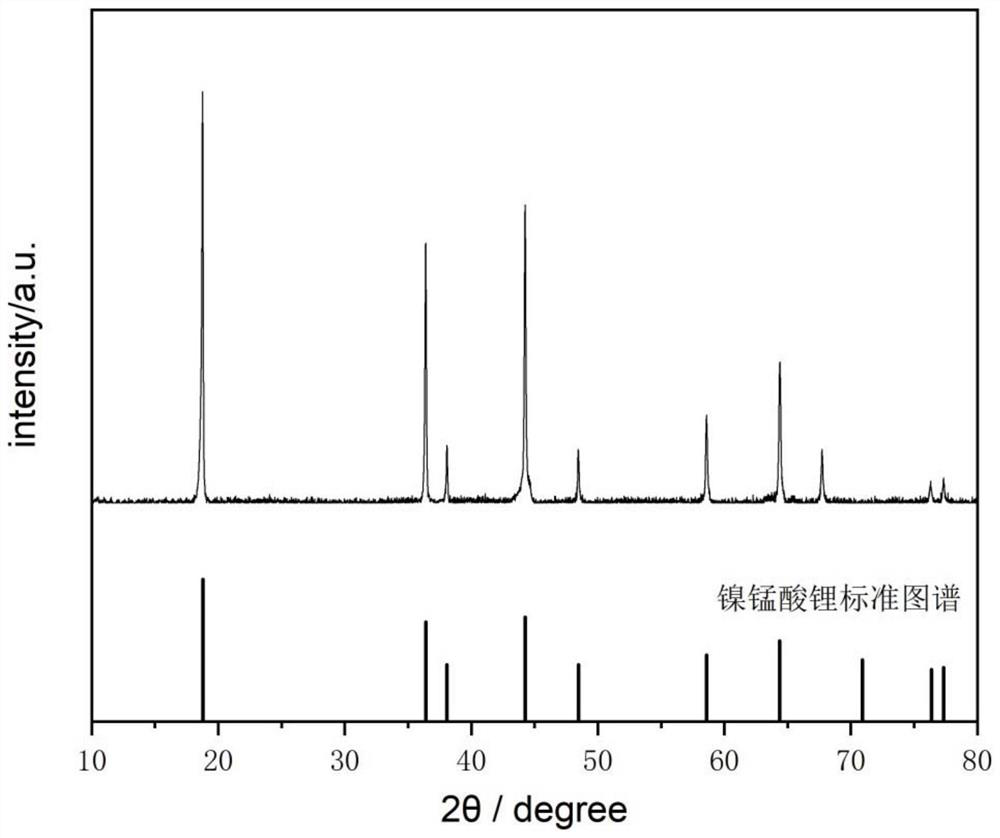

Atomic-scale doped lithium nickel manganese oxide positive electrode material as well as preparation method and application thereof

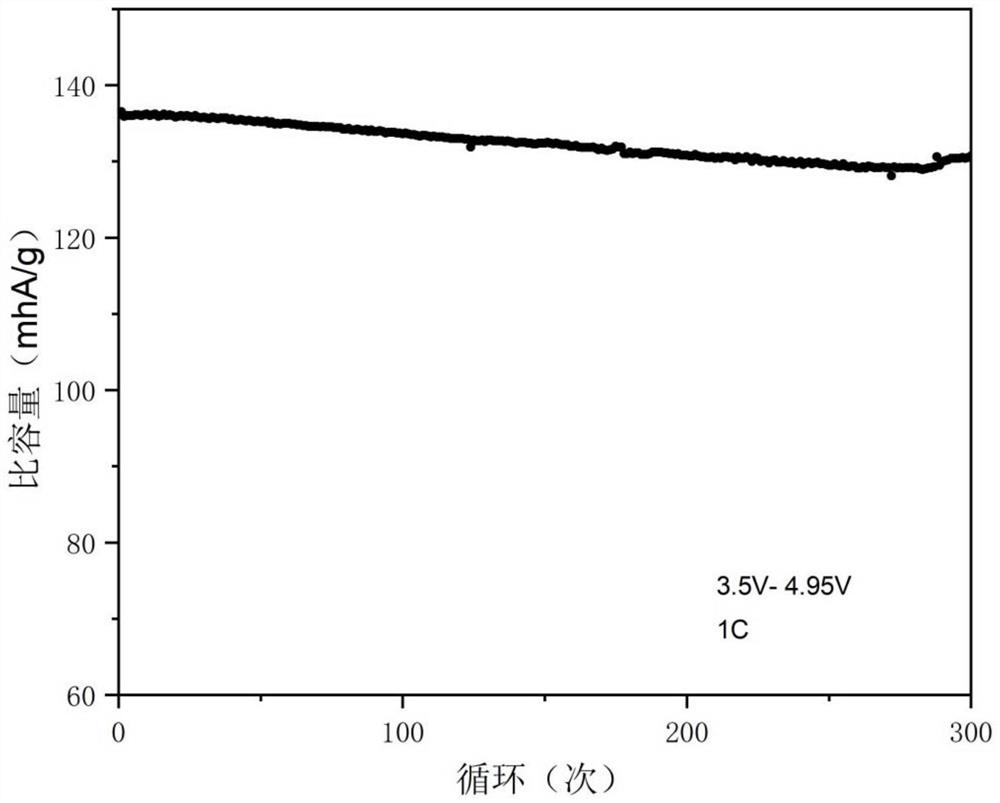

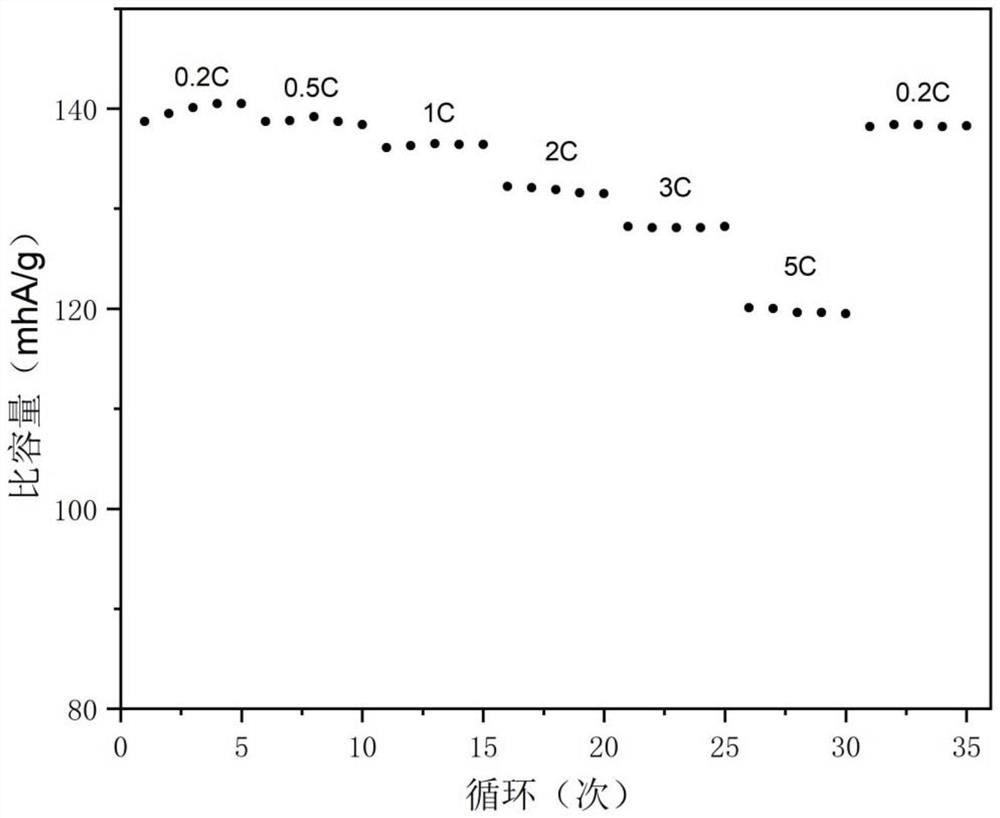

A technology of lithium nickel manganate and cathode material, which is applied in the field of atomic-level doped lithium nickel manganate cathode material and its preparation, can solve the problems of capacity decrease, destroy the structural integrity of crystal structure, etc., so as to improve the stability and improve the cycle. Stability and the effect of suppressing the loss of Mn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Weigh 2.0g (0.008mol) of manganese acetylacetonate and dissolve it in 50mL of ethylene glycol solution, and add 1.0g of polyvinylpyrrolidone-K15 at a stirring rate of 300rpm, heat up after it is completely dissolved, and react at 170°C for 6h, A white precipitate was obtained;

[0032] (2) Wash the white precipitate with ethanol, then dry the white precipitate, and finally calcinate the white precipitate in a muffle furnace at 700°C for 4h at a heating rate of 2°C / min to obtain flaky manganese trioxide.

[0033] (3) Weigh 0.392g of flaky manganese trioxide, 0.126g of nickel oxide, and 0.137g of lithium carbonate, then add 0.017g of cerium oxide, disperse it all in ethanol and stir at room temperature for 20h, then place in a vacuum oven Dry in medium temperature, and finally use a ball mill to grind the material for 6 hours at a speed of 600 rpm.

[0034] (4) The homogeneously mixed material was directly calcined at a high temperature at a temperature of 950°C, a c...

Embodiment 2

[0039] (1) Weigh 1.5g (0.006mol) of manganese acetylacetonate and dissolve it in 50mL of ethylene glycol solution, and add 20mL of ethanolamine at a stirring rate of 200rpm, heat up after it is completely dissolved, and react at 190°C for 2 hours to obtain a white precipitate;

[0040] (2) Wash the white precipitate with ethanol, then dry the white precipitate, and finally calcinate the white precipitate in a muffle furnace at 600°C for 2h at a heating rate of 1°C / min to obtain flaky manganese trioxide.

[0041](3) Weigh 0.49g of flaky manganese trioxide, 0.196g of nickel hydroxide, 0.446g of L-lithium lactate, add 0.022g of hexapraseodymium undecoxide, disperse them all in ethanol and stir at room temperature for 22h , and then dry in a vacuum oven, and finally use a ball mill to grind the material for 5 hours at a speed of 800 rpm.

[0042] (4) The homogeneously mixed material is directly calcined at high temperature at a temperature of 900°C, a constant temperature time of ...

Embodiment 3

[0044] (1) Weigh 1.0g (0.004mol) of manganese acetylacetonate and dissolve it in 40mL of ethylene glycol solution, add 0.8g of polyethylene glycol 2000, stir at 100rpm, heat up after it is completely dissolved, and react at 195°C for 3h. A white precipitate was obtained;

[0045] (2) Wash the white precipitate with ethanol, then dry the white precipitate, and finally calcinate the white precipitate in a muffle furnace at 500°C for 5h at a heating rate of 1°C / min to obtain flaky manganese trioxide.

[0046] (3) Weigh 0.49g of flaky manganese trioxide, 0.386g of nickel oxalate dihydrate, 0.237g of lithium oxalate, add 0.034g of samarium trioxide, disperse it all in ethanol and stir at room temperature for 24h, then Dry in a vacuum oven, and finally use a ball mill to grind the material for 8 hours at a speed of 500 rpm.

[0047] (4) The homogeneously mixed material is directly calcined at high temperature at a temperature of 1000°C, a constant temperature time of 24h, a heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com