Preparation method of mesoporous metal oxide catalytic material

A technology of catalytic materials and oxides, applied in the direction of metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, chemical instruments and methods, etc., can solve the problem of difficult mesopore structure and easy aggregation of metal oxide grains , maintenance and difficult to control the pore size, to achieve the effect of simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 2.56g of cerium nitrate and 2.53g of zirconium nitrate and dissolve them in 5mL of ethanol respectively. Then the ethanol solutions of cerium nitrate and zirconium nitrate were mixed, and stirred at a speed of 700 r / min for 2 hours by magnetic stirring to obtain the ethanol solution of the metal precursor. Place the metal precursors in a vacuum oven at 80 °C to remove the solvent. Finally, the templating agent is removed by 600°C temperature-programmed calcination to obtain the mesoporous transition metal oxide material.

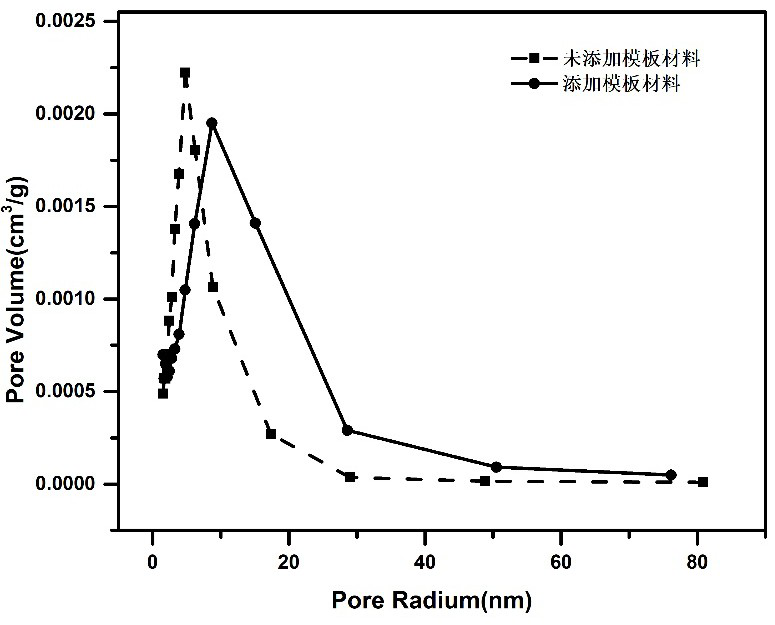

[0031] The transition metal oxide obtained by this method has a porous structure, and its pore radius distribution is concentrated between 0 and 30 nm, and its pore radius distribution is as follows: image 3 shown.

Embodiment 2

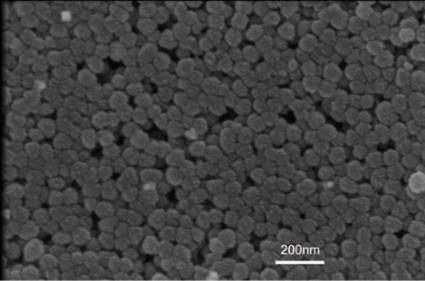

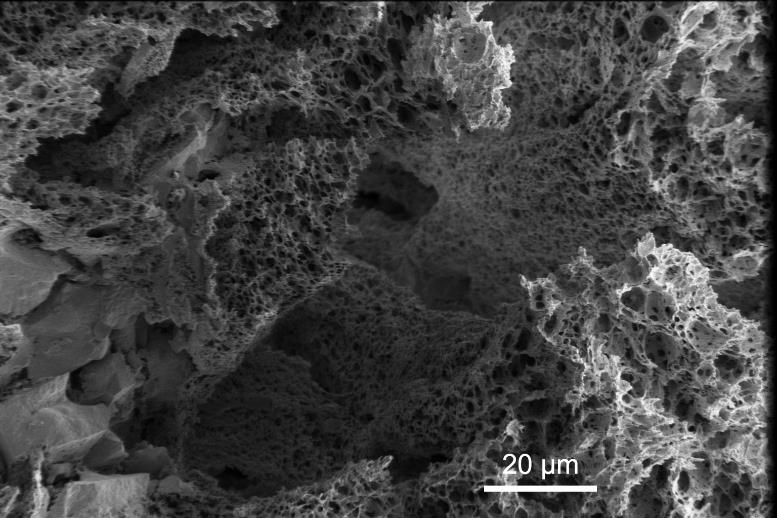

[0033] Firstly, the template material is prepared, and polyacrylonitrile nanoparticles are prepared by emulsion polymerization with acrylonitrile as a monomer. The particle size of the nanoparticles is 70nm, and the scanning electron microscope picture is as figure 1 shown. Using this as a template, the polymer particle dispersion was placed in a clean petri dish to dry to obtain a thin sheet formed by the particles, and its surface morphology was as follows: figure 1 shown. Weigh 2.56g of cerium nitrate and 2.53g of zirconium nitrate and dissolve them in 5mL of ethanol respectively. Then the ethanol solutions of cerium nitrate and zirconium nitrate were mixed, and stirred at a speed of 700 r / min for 2 hours by magnetic stirring to obtain the ethanol solution of the metal precursor. The thin sheet formed by assembling the template material was immersed in the ethanol solution of the metal precursor, and filtered to remove excess metal precursor solution after immersion for 2...

Embodiment 3

[0036] First, a template material was prepared, and polyphenolic resin nanoparticles were prepared by emulsion polymerization with phenol and formaldehyde as monomers. The particle size of the nanoparticles was 50 nm, and this was used as a template material. Weigh 2.56g of cerium nitrate and 0.25g of zirconium nitrate and dissolve them in 5mL of ethanol respectively. Then the ethanol solutions of cerium nitrate and zirconium nitrate were mixed, and stirred at a speed of 700 r / min for 2 hours by magnetic stirring to obtain the ethanol solution of the metal precursor. The dispersion of the template material is mixed with the ethanol solution of the metal precursor, and the amount of the dispersion of the template material is between 2 and 5 g. The mixed solution was placed in a vacuum oven at 80° C. to remove the solvent. Finally, the templating agent is removed by temperature-programmed calcination at 600° C. to obtain a mesoporous transition metal oxide material.

[0037] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com