Biomass waste residue-based monatomic metal catalyst as well as preparation method and application thereof

A metal catalyst and biomass technology, which is applied in the field of biomass waste residue-based single-atom metal catalyst and its preparation, can solve the problems of unfavorable single-atom catalyst for large-scale production and application, high cost, harsh preparation conditions, etc. Utilization rate, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

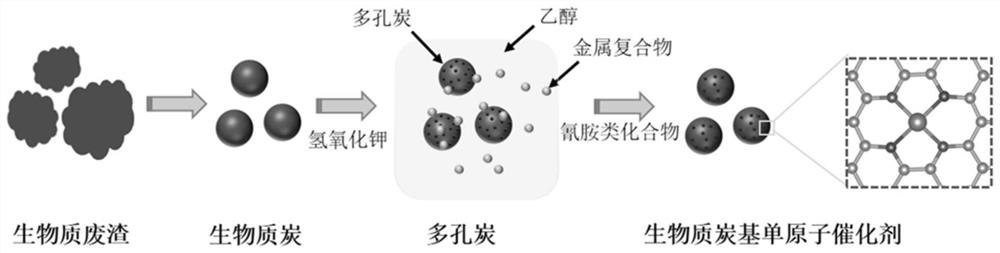

[0028] The invention provides a method for preparing a biomass waste slag-based single-atom metal catalyst such as figure 1 As shown, the method includes the following steps:

[0029] 1) Drying, pulverizing, and sieving the biomass waste residue to obtain waste residue powder, and then performing oxygen-limited pyrolysis to obtain biochar;

[0030] 2) mixing the biochar with potassium hydroxide solution, stirring, then drying, and then performing secondary pyrolysis under oxygen-limited conditions to obtain porous carbon;

[0031] 3) Dissolve the metal precursor and o-phenanthroline in an organic solvent, then add porous carbon, stir, and then dry to obtain a powder, mix the powder with a cyanamide compound evenly, and sinter in a protective atmosphere, that is A biomass waste slag-based single-atom metal catalyst is obtained.

[0032] In step 1), the biomass waste residue includes one or more of furfural residue, biogas residue, activated sludge, and coffee grounds, and the...

Embodiment 1

[0038] 1. Preparation of biochar

[0039] After drying 10g of furfural slag, crush it with a crusher and pass through a 200-mesh sieve to obtain finely divided furfural slag powder, transfer it to a crucible to fill it up, and pyrolyze it at 600°C for 2 hours with limited oxygen to obtain biochar.

[0040] 2. Preparation of porous carbon carrier

[0041] 6g of biochar and 500mL of 0.42mol / L KOH mixed solution were stirred for 0.5h, then transferred to an oven for drying, then transferred to a crucible, and pyrolyzed at 800°C for 2h under oxygen-limited conditions to obtain porous carbon.

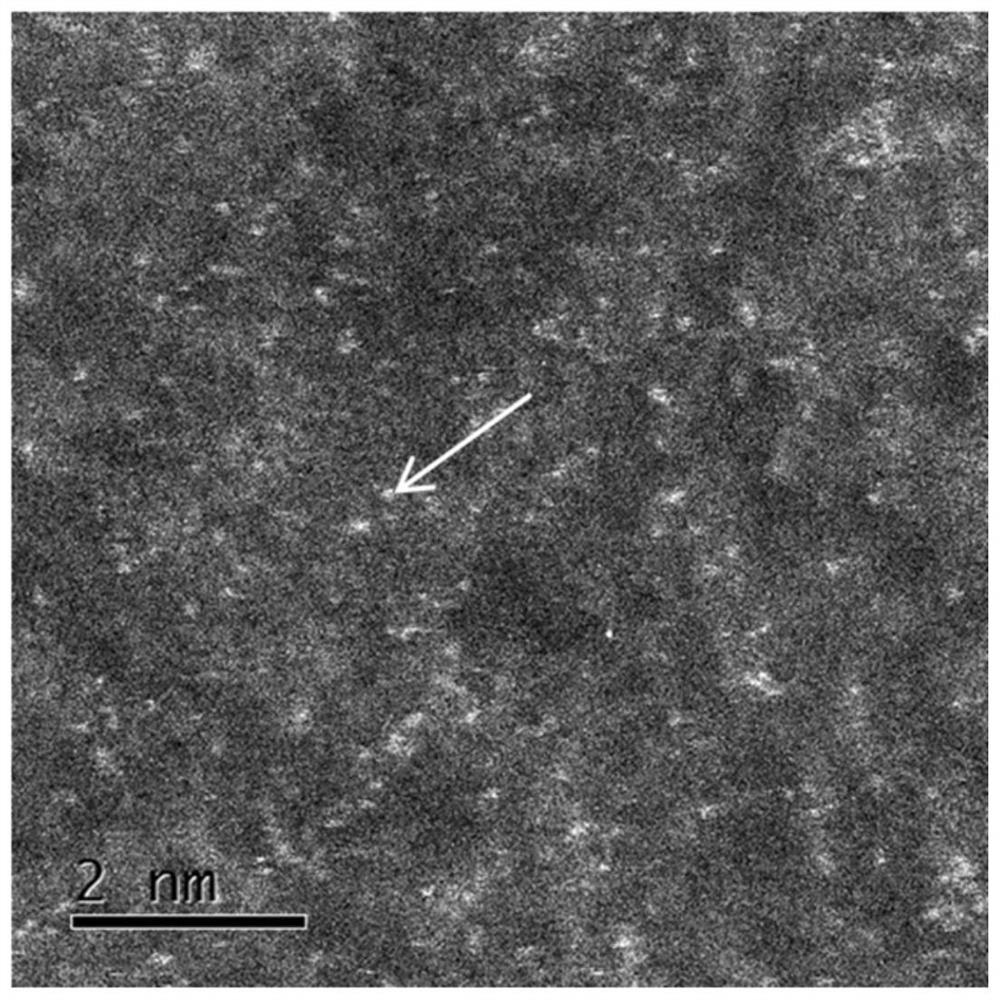

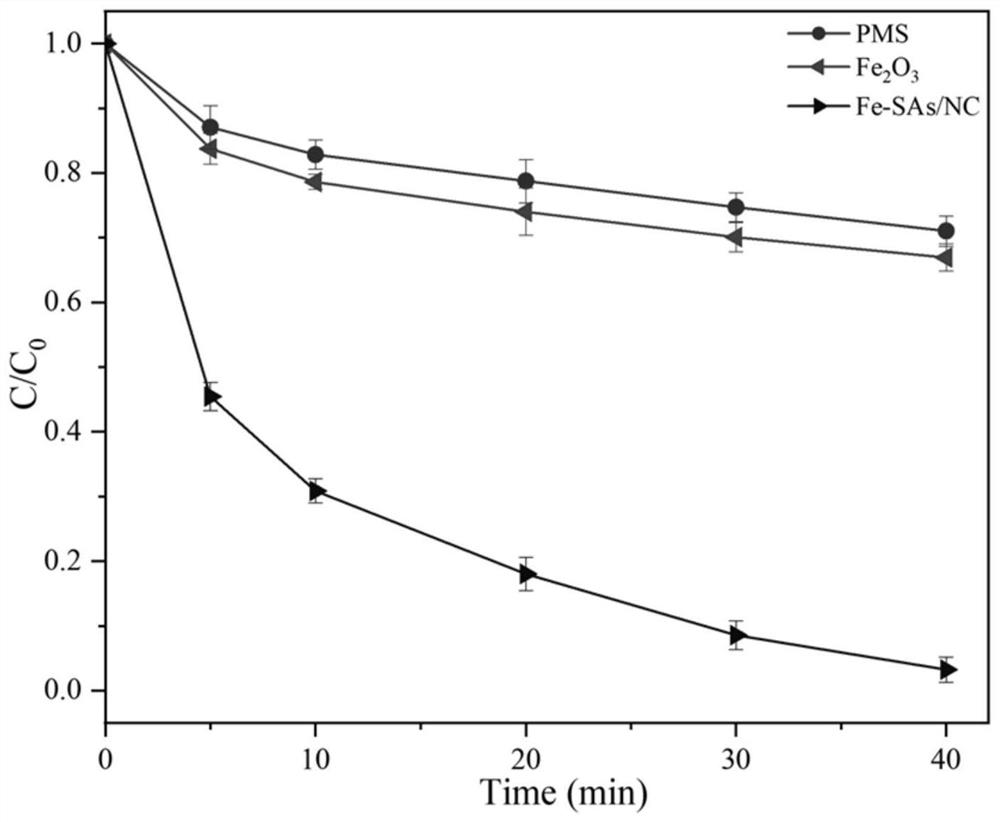

[0042] 3. Preparation of biomass waste residue-based monatomic iron catalyst

[0043] 0.4mmol of ferrous acetate and 2.0mmol of o-phenanthroline monohydrate were dissolved in 50mL of ethanol to obtain a mixed solution, 300mg of porous carbon was placed in the mixed solution and stirred for 0.5h, then dried to obtain a powder, which was mixed with melamine in a mass ratio of 1:4 Grind in a ...

Embodiment 2

[0047] 1. Preparation of biochar

[0048] After drying 20g of furfural slag, crush it with a crusher and pass through a 100-mesh sieve to obtain finely divided furfural slag powder, transfer it to a crucible to fill it up, and pyrolyze it at 700°C for 3 hours with limited oxygen to obtain biochar.

[0049] 2. Preparation of porous carbon carrier

[0050] Stir 10 g of biochar with 200 mL of 1.8 mol / L KOH mixed solution for 1 h, transfer to an oven for drying, then transfer to a crucible for compaction, and pyrolyze at 800 °C for 3 h under oxygen-limited conditions to obtain porous carbon.

[0051] 3. Preparation of biomass waste residue-based single-atom cobalt catalyst

[0052] 0.6mmol of cobaltous acetate and 3.0mmol of o-phenanthroline monohydrate were dissolved in 30mL of ethanol to obtain a mixed solution, 500mg of porous carbon was placed in the mixed solution and stirred for 0.5h, and then dried to obtain a powder, which was mixed with melamine in a mass ratio of 1:5 G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com