Hafnium diboride-silicon carbide-tantalum disilicide-gadolinium oxide composite coating and preparation method thereof

A technology of tantalum disilicide and hafnium diboride, which is applied in coating, metal material coating process, fusion spraying, etc., can solve the problem of low high-temperature emissivity of oxidation products, improvement of coating oxidation rate, and coating oxygen barrier ability Dropping and other problems, to achieve the effect of retaining the characteristics of powder materials, reducing coating defects, and improving the compactness of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

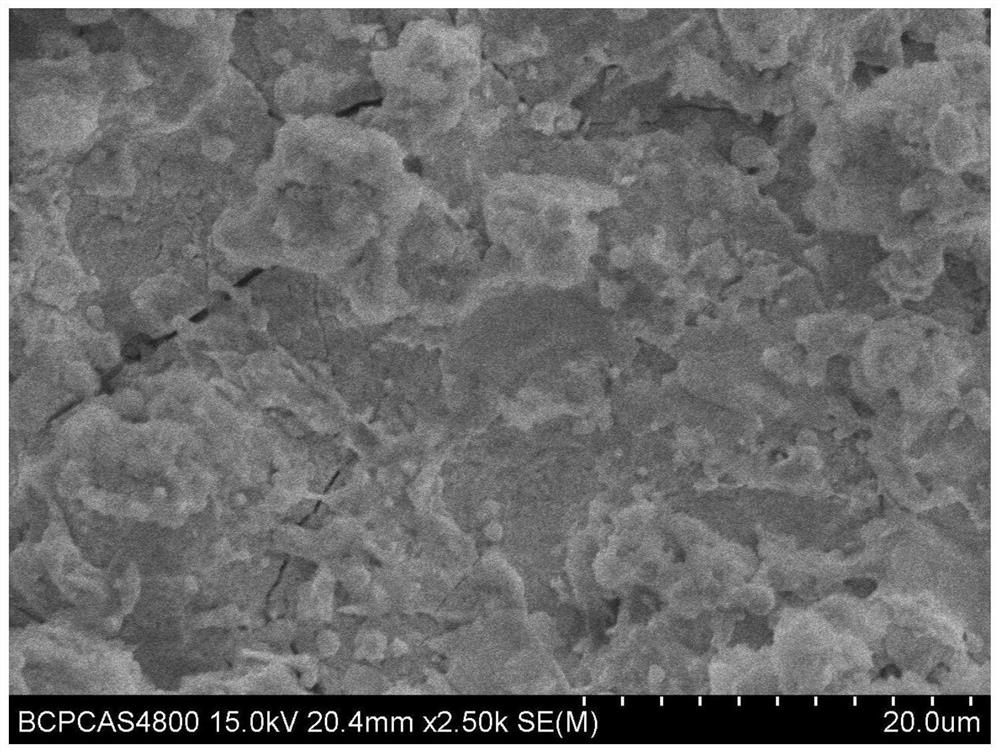

[0031] The invention provides a preparation method of hafnium diboride-silicon carbide-tantalum disilicide-gadolinium oxide composite coating, comprising the following steps:

[0032] Preheat the substrate, and spray the hafnium diboride-silicon carbide-tantalum disilicide-gadolinium oxide composite powder on the surface of the preheated substrate by atmospheric plasma spraying to obtain the hafnium diboride-silicon carbide-tantalum disilicide-gadolinium oxide composite coating layer;

[0033] The hafnium diboride-silicon carbide-tantalum disilicide-gadolinium oxide composite powder is in a molten eutectic state, and its components include the following components in volume percentage:

[0034]

[0035] In the present invention, the substrate is preheated first. In the present invention, the matrix is preferably a matrix that requires high-temperature anti-oxidation protection on the surface; further, the matrix is preferably a carbon fiber-reinforced carbon-matrix com...

Embodiment 1

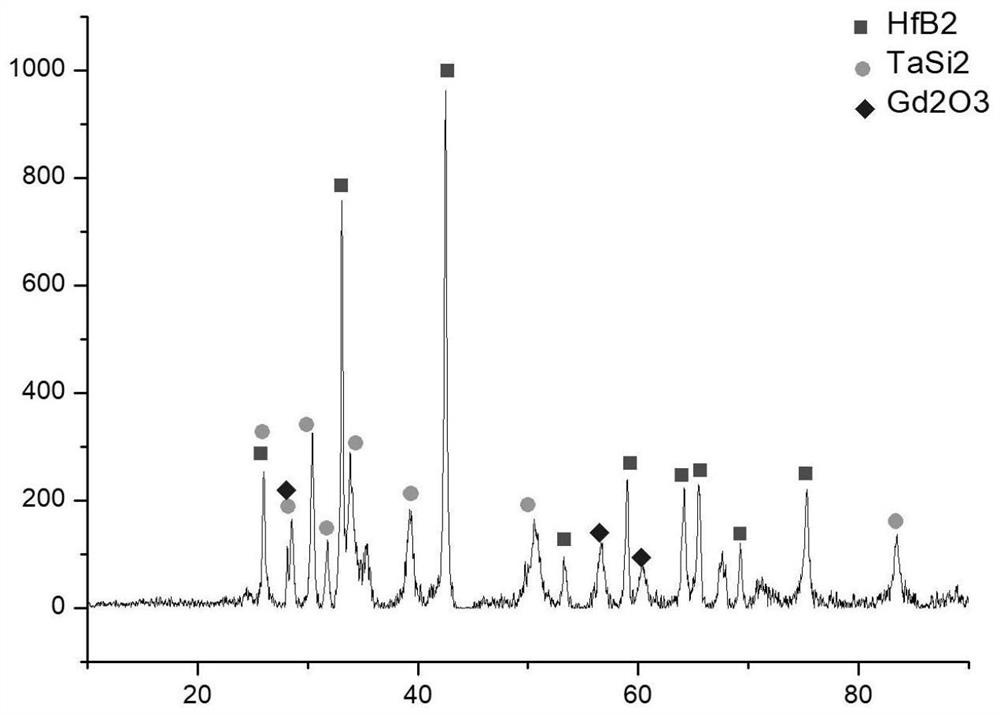

[0088] (1) Add 1150g of hafnium diboride, 75g of silicon carbide, 214g of tantalum disilicide, 61g of gadolinium oxide, 7.5g of PVA and 2250g of deionized water into the ball mill tank with a ball-to-material ratio of 4:1, and ball mill at 250r / min 3h, make each component mix uniformly, obtain the suspension of precursor powder;

[0089] (2) Transfer the suspension obtained in step (1) to a spray drying granulation tower for agglomeration and granulation. The granulated powder is first dried in an oven at 80°C for 30 hours, and then passed through a test sieve to obtain granules. HfB with diameter2 -SiC-TaSi 2 -Gd 2 o 3 Agglomerated powder (HfB 2 , SiC, TaSi 2 、Gd 2 o 3 The volume ratio is 66.5:14.25:14.25:5);

[0090] Among them, the spray drying granulation parameters are: inlet temperature 250°C, outlet temperature 130°C, nozzle speed 35Hz, peristaltic pump speed 30rpm;

[0091] (3) HfB 2 -SiC-TaSi 2 -Gd 2 o 3The agglomerated powder is sent to the induction plas...

Embodiment 2

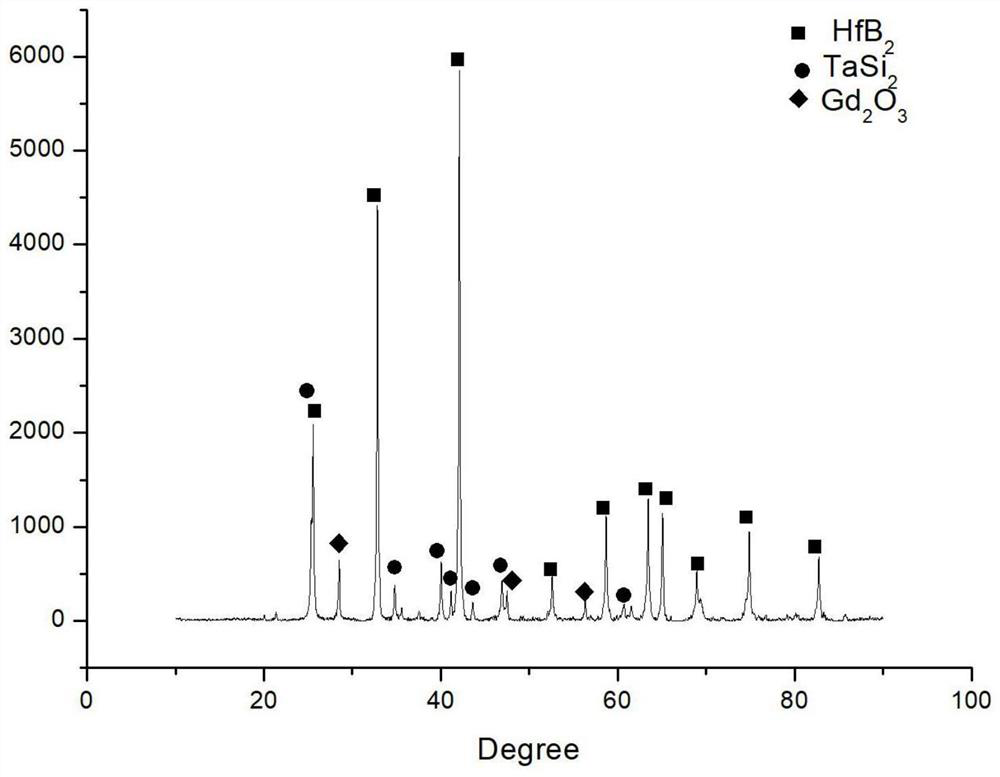

[0102] (1) Add 1101g of hafnium diboride, 72g of silicon carbide, 204g of tantalum disilicide, 123g of gadolinium oxide, 7.5g of PVA and 2250g of deionized water into the ball mill tank with a ball-to-material ratio of 4:1, and ball mill at 400r / min 2h, make each component mix uniformly, obtain the suspension of precursor powder;

[0103] (2) Transfer the suspension obtained in step (1) to a spray drying granulation tower for agglomeration and granulation. The granulated powder is first dried in an oven at 150°C for 20 hours, and then passed through a test sieve to obtain granules. HfB with diameter2 -SiC-TaSi 2 -Gd 2 o 3 Agglomerated powder (HfB 2 , SiC, TaSi 2 、Gd 2 o 3 The volume ratio is 63:13.5:13.5:10);

[0104] Among them, the spray drying granulation parameters are: inlet temperature 250°C, outlet temperature 130°C, nozzle speed 35Hz, peristaltic pump speed 35rpm;

[0105] (3) HfB 2 -SiC-TaSi 2 -Gd 2 o 3 The agglomerated powder is sent to the induction plas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com