Preparation method of polyether ester type melt-spun spandex slices

A technology of polyether ester and melt spinning, applied in textiles and papermaking, single-component synthetic polymer rayon, fiber chemical characteristics, etc., can solve the problem of inability to guarantee the uniformity, controllability, mechanical strength, and heat resistance of the reaction system Resilience decreases, different reaction rates of isocyanates, etc., to achieve the effect of high molecular weight, narrow molecular weight distribution, and uniform reaction system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

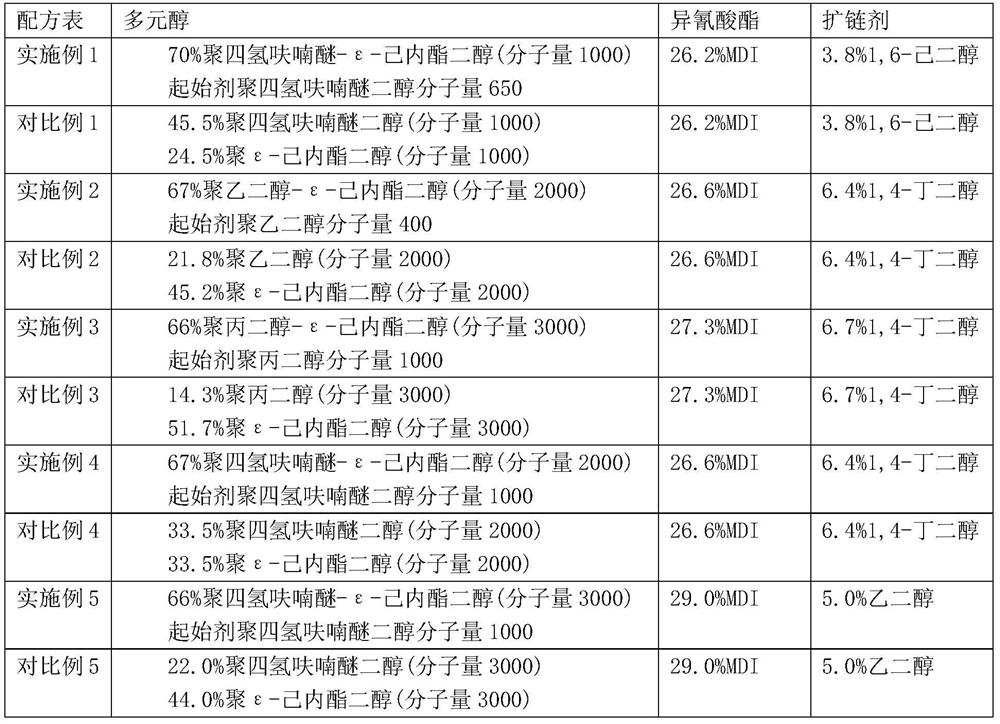

[0022] A method for preparing polyether ester type melt-spun spandex chips, the polyether ester type melt-spun spandex chips first use polyether polyol as an initiator to initiate ring-opening polymerization of ε-caprolactone to form polyether-ε -Caprolactone polyol, then add small molecule chain extender and isocyanate to the twin-screw reaction extruder at a molar ratio of 1:(0.5~3.7):(1.5~5.3) for extruding and manufacturing Granules, dried.

[0023] Wherein, the number average molecular weight of the polyether-ε-caprolactone polyol is 1000~3000; the preparation method of the polyether-ε-caprolactone polyol comprises the following steps:

[0024] A. The polyether polyol is dewatered under vacuum at 100-150°C, and the ε-caprolactone raw material is dewatered under vacuum at 90-110°C, until the moisture content is below 500ppm.

[0025] B. Add polyether polyol and ε-caprolactone with a molar ratio of 1:(3~18) to remove water into the reactor, stir evenly at 120°C, add 50~500...

Embodiment approach

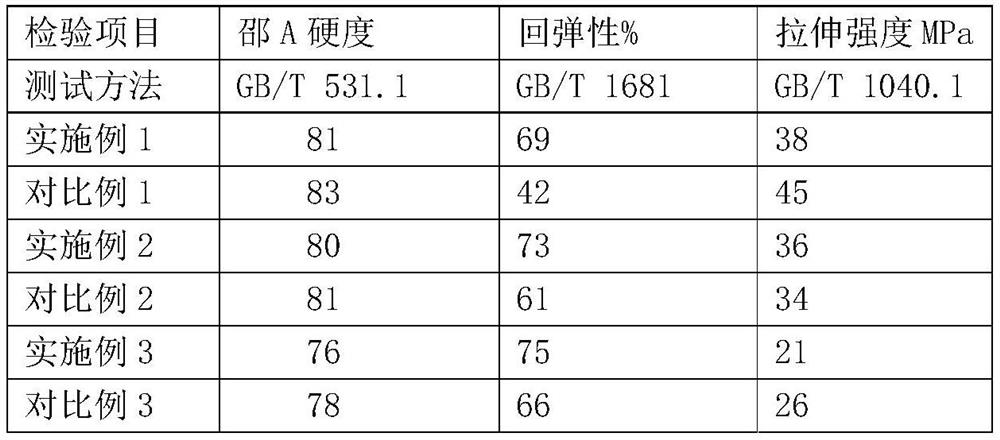

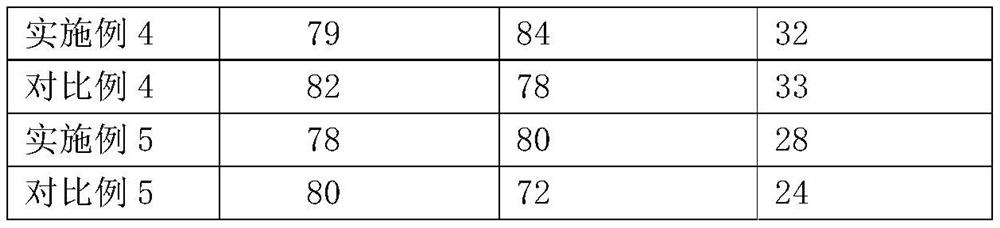

[0030] The test methods or test methods described in the following examples, unless otherwise specified, are conventional methods; the reagents and materials, unless otherwise specified, are obtained from conventional commercial channels or prepared by conventional methods.

[0031] The molecular weight described in the present invention is the number average molecular weight. Before the raw materials are used, water is removed under reduced pressure to a moisture content below 500 ppm, and parts by mass are used in the following examples.

Embodiment 1

[0033] Add 65 parts of polytetrahydrofuran ether diol (molecular weight 650) and 35 parts of ε-caprolactone into the reactor, stir well at 120°C, add 50ppm tetrabutyl titanate, blow nitrogen, raise the temperature to 160°C for 4 hours, and the acid value 0.45mgKOH / g, the acid value was 0.12mgKOH / g after vacuuming for 4 hours, and the reaction was completed to obtain polytetrahydrofuran ether-ε-caprolactone diol with a molecular weight of 1000.

[0034] Inject 70 parts of the obtained polytetrahydrofuran ether-ε-caprolactone diol, 3.8 parts of 1,6-hexanediol, and 26.2 parts of 4,4'-diphenylmethane diisocyanate into the twin-screw extruder with a metering pump In the machine, after extrusion at 190°C, it is pelletized underwater, dried, and packaged to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com