Municipal solid waste heat treatment-chemical chain gasification coupling hydrogen production system and method

A municipal solid waste and chemical chain technology, applied in the field of waste treatment, can solve the problems of containing and restricting the promotion and application of waste incineration, and achieve the effects of avoiding the generation of dioxin, improving the oil yield and oil-water separation effect, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

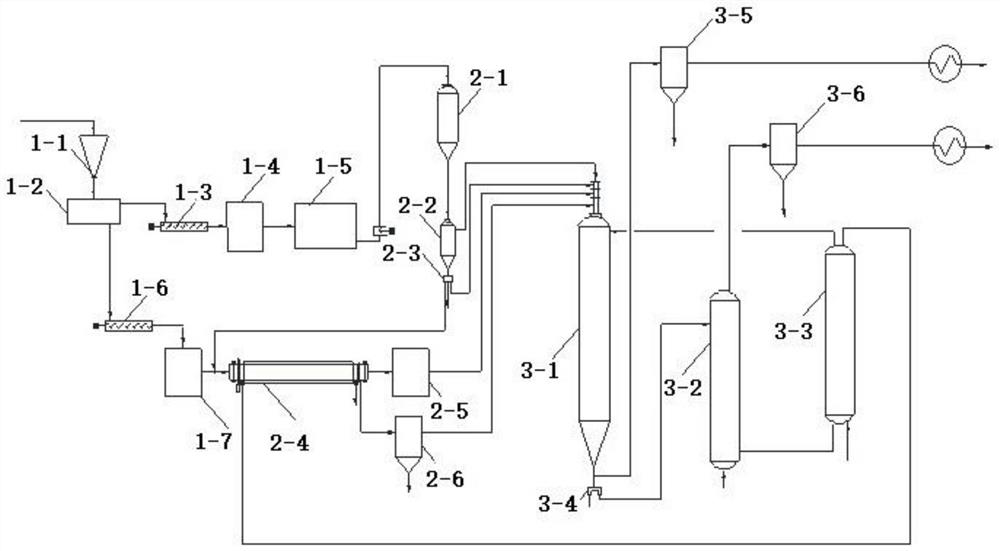

[0072] Such as figure 1 and figure 2 As shown, the municipal solid waste heat treatment-chemical looping gasification coupled hydrogen production system in this embodiment includes a pretreatment unit, a heat treatment unit, a chemical looping gasification coupled hydrogen production unit and a waste heat utilization unit connected in sequence;

[0073] The pretreatment unit includes a dry-wet sorting device 1-2 and a feed hopper 1-1 connected to the dry-wet sorting device 1-2, and the first outlet of the dry-wet sorting device 1-2 is successively It is connected with the first screw feeder 1-3 and the first crushing equipment 1-4, the outlet of the first crushing equipment 1-4 is connected with the mixing tank 1-5, and the dry and wet separation equipment 1-2 The second outlet of the second screw feeder is connected with the second screw feeder 1-6 and the second crushing equipment 1-7 in turn;

[0074] The heat treatment unit includes a first heat treatment reactor 2-1 co...

Embodiment 2

[0093] In this embodiment, wet combustible garbage is selected from kitchen waste, and the proportion of kitchen waste is shown in Table 1, wherein the base water of kitchen waste is 80% (wt), and dry combustible garbage is selected from waste plastics and waste rubber, household garbage The analytical data are shown in Table 2, and the analytical results are air-dry bases:

[0094] Table 1 The proportion of types of kitchen waste

[0095]

[0096] Table 2 Domestic waste analysis data

[0097]

[0098] In this example, the feed rate of municipal solid waste is 50kg / h, and the mass ratio of wet combustible waste and dry combustible waste entering the heat treatment system is 7:3, wherein the mass ratio of waste plastics and waste rubber in dry combustible waste is 1: 1.

[0099] This embodiment includes the following steps:

[0100] Step 1. Pretreatment: The municipal solid waste is sent to the dry and wet sorting equipment 1-2 through the hopper 1-1 for separation to ...

Embodiment 3

[0111] Wet combustible waste selects biomass among the present embodiment, and wherein the receiving base of biomass is 40% (wt) in total moisture, and dry combustible waste selects waste rubber and paper, and the analysis data of house refuse is as shown in table 4, and analysis result is Air dry basis:

[0112] Table 4 Domestic waste analysis data

[0113]

[0114]

[0115] In this example, the feed rate of municipal solid waste is 50kg / h, the mass ratio of wet combustible waste and dry combustible waste entering the heat treatment system is 7:3, and the mass ratio of waste rubber and paper in dry combustible waste is 1:1 .

[0116] This embodiment includes the following steps:

[0117] Step 1. Pretreatment: The municipal solid waste is sent to the dry and wet sorting equipment 1-2 through the hopper 1-1 for separation to obtain wet combustible garbage and dry combustible garbage, and then the wet combustible garbage is fed through the first screw The machine 1-3 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com