Method for preparing fat-soluble nutrient microcapsules

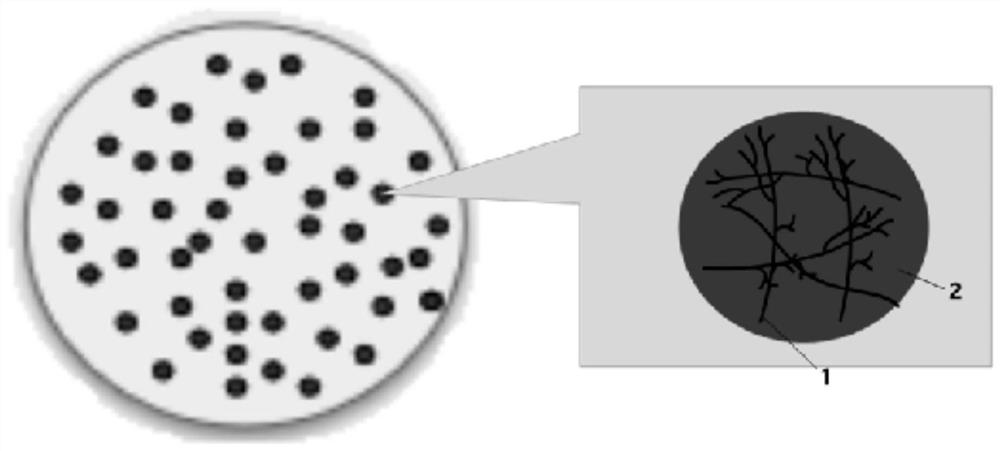

A technology of fat-soluble nutrients and microcapsules, which is applied in the direction of microcapsule preparation, microsphere preparation, food forming, etc., can solve the problems of low processing resistance of microcapsules, achieve improved processing stability, reduce steric hindrance, The effect of increasing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

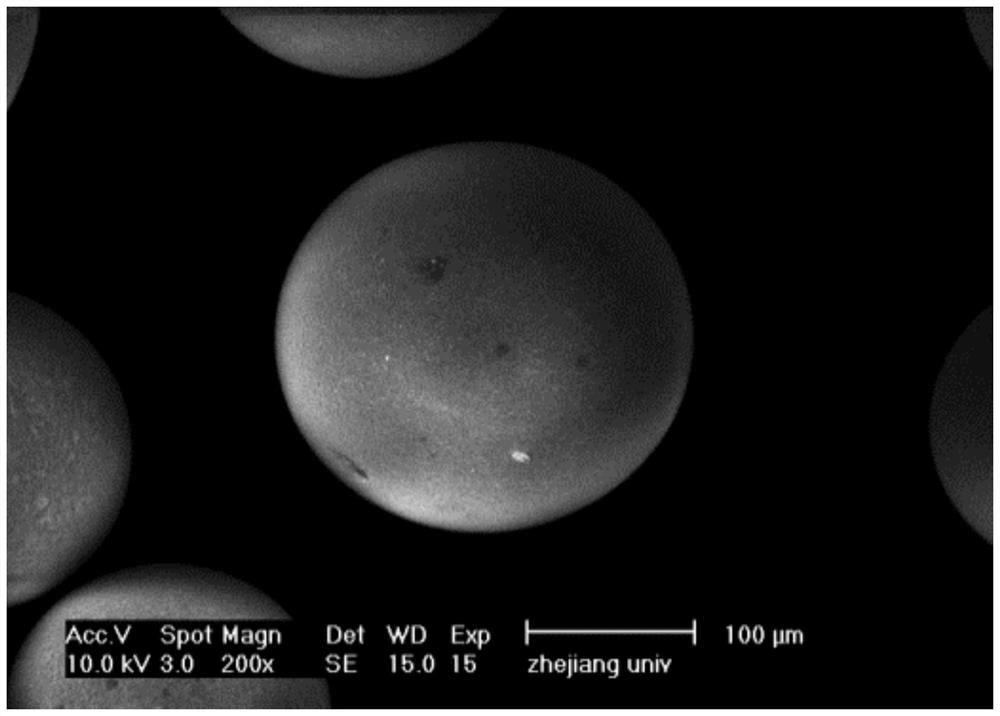

[0029] (1) Preparation of the oil phase: 4 g of Span 80 and 4 g of Tween 80 were used as emulsifiers, dissolved in 100 g of vitamin E, stirred evenly at 45°C, and used as the oil phase;

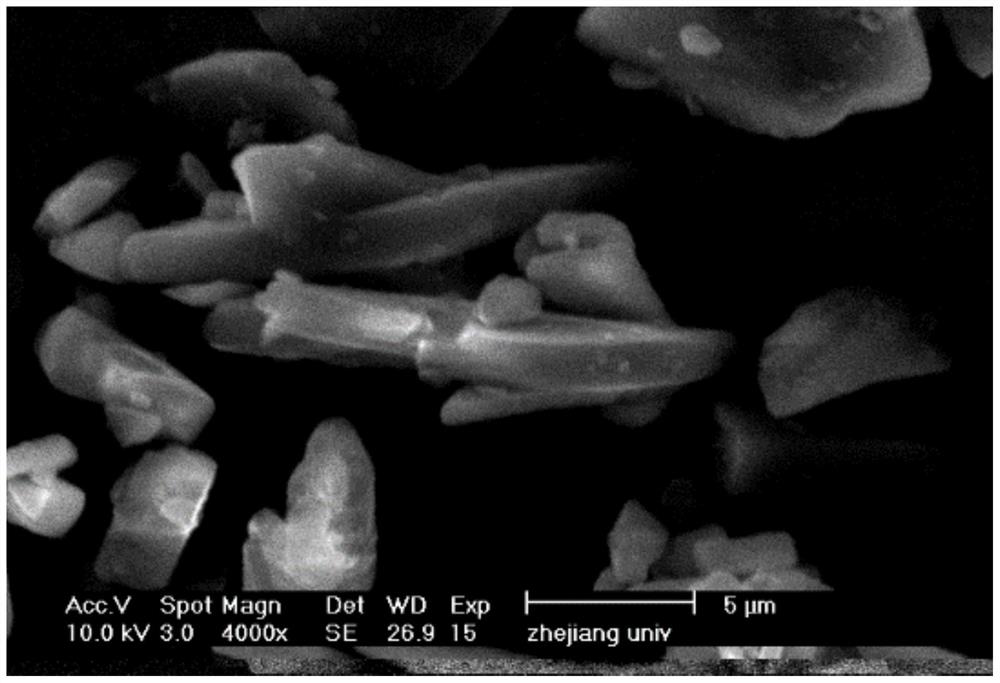

[0030] (2) Water phase preparation: add 10 mL of deionized water to 1 g of waxy corn starch, treat in an oil bath at 120 ° C for 30 min, add 10 mL of an aqueous solution in which 0.01 g of sodium trimetaphosphate is dissolved while stirring, and add while stirring, as the water phase ;

[0031] (3) W / O emulsion preparation: add the water phase to the oil phase dropwise to form a water-in-oil emulsion (W / O);

[0032] (4) Preparation of W / O / W emulsion: Weigh 200g of waxy corn starch octenyl succinate and 200g of water, stir evenly at 40-45°C until completely dissolved, and add 0.02g of sodium trimetaphosphate to obtain water Sol solution; the water-in-oil emulsion obtained in step (3) is slowly added to the hydrosol solution to form a W / O / W emulsion;

[0033] (5) Pre-reaction: Stir the W / O / W ...

Embodiment 2-5

[0038] After adjusting the types of fat-soluble nutrients and their mass ratios to Span and Tween in Step 1, refer to Example 1 for other conditions and preparation methods.

[0039]

Embodiment 6-10

[0041] The starch type in step 2 and its pretreatment method and the type of crosslinking agent, starch: crosslinking agent: water mass ratio are adjusted according to the following table, vitamin A is used for fat-soluble nutrients, and other conditions and preparation methods refer to Example 1 .

[0042]

[0043] The octenyl succinic acid waxy corn starch ester in the above example 6 is 1 part of waxy corn starch and 0.03 part of octenyl succinic anhydride at pH = 8, 40 degrees for 3 hours, after the reaction, the pH is adjusted to Neutral, filtered, washed with deionized water for 5 times, and finally dried to obtain starch octenyl succinate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com