Medical material surface chitosan/graphene oxide coating and preparation method thereof

A technology of chitosan and graphene, applied in the field of biomedicine, can solve problems such as implant failure and high infection rate, achieve the effects of avoiding local inflammation, strong controllability, and improving antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

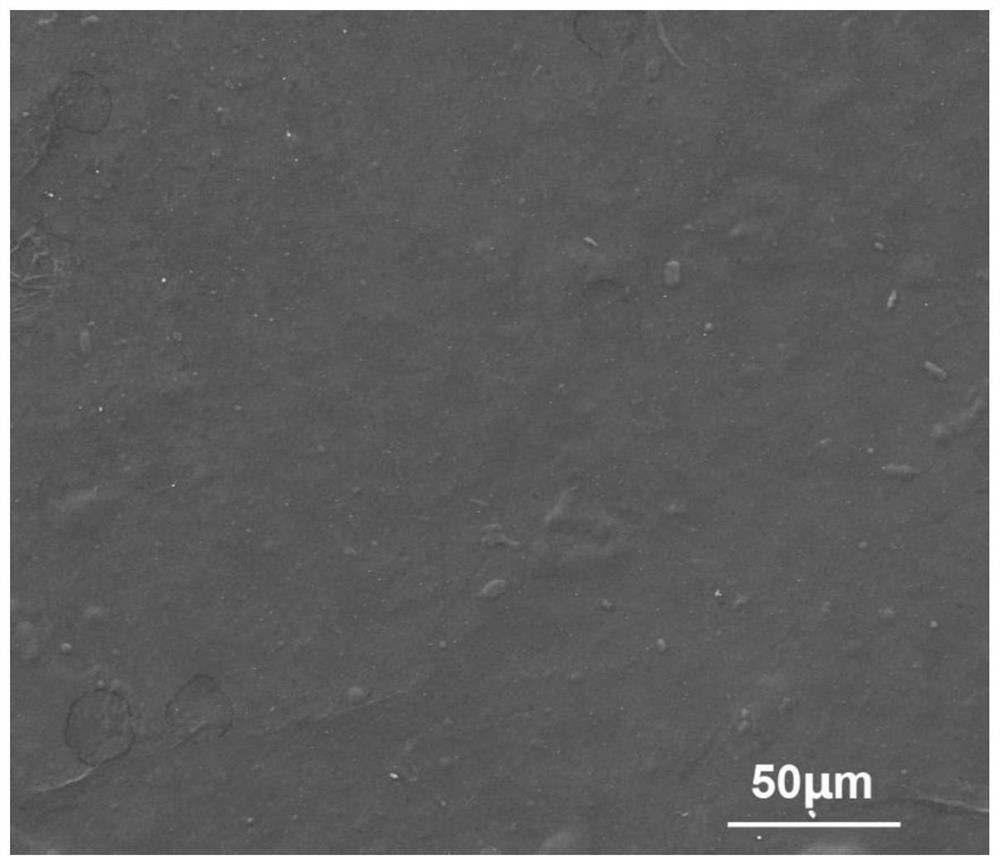

[0049] 1) Prepare a fluorine-substituted hydroxyapatite coating (FHA coating for short, the detailed preparation process can refer to "Electrodeposition of Ca-P coatings on biodegradable Mgalloy: In vitro biomineralization behavior") on the surface of the magnesium alloy substrate by electrodeposition method, and Place in a vacuum drying oven at 60°C for 12 hours;

[0050] 2) Prepare a 5 mg / mL graphene oxide aqueous solution, ultrasonically disperse for 2 hours, and prepare a graphene oxide dispersion;

[0051] 3) Put 0.2 g of chitosan into 10 mL of distilled water, add 0.1 mL of glacial acetic acid, stir with a magnetic stirrer for 24 hours until the chitosan is completely dissolved, and prepare an aqueous solution of chitosan;

[0052] 4) Get 2mL of the dispersed graphene oxide dispersion and slowly add it to the chitosan solution, using a magnetic stirrer and ultrasonic waves alternately until forming a uniformly dispersed chitosan / graphene oxide solution;

[0053] 5) Submer...

Embodiment 2

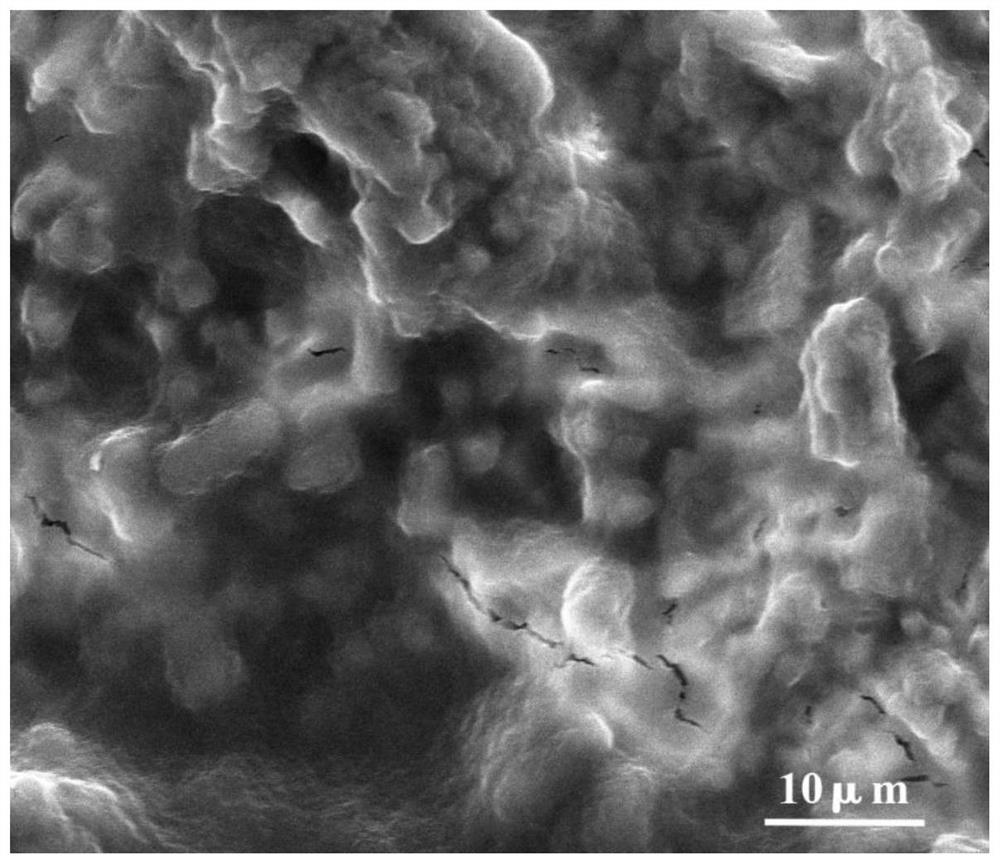

[0056] 1) Electrodeposition is used to prepare calcium zincite coating (SLZ coating for short, please refer to "Synthesis and degradation behavior of Zn modified coating on Mgalloy" for detailed preparation process) on the surface of magnesium alloy substrate, and put it in a vacuum drying oven for 60 ℃ drying for 12 hours;

[0057] 2) Prepare a 2 mg / mL graphene oxide aqueous solution, ultrasonically disperse for 2 hours, and prepare a graphene oxide dispersion;

[0058] 3) Put 0.2 g of chitosan into 10 mL of distilled water, add 0.1 mL of glacial acetic acid, stir with a magnetic stirrer for 24 hours until the chitosan is completely dissolved, and prepare an aqueous solution of chitosan;

[0059] 4) Get 2mL of the dispersed graphene oxide dispersion and slowly add it to the chitosan solution, using a magnetic stirrer and ultrasonic waves alternately until forming a uniformly dispersed chitosan / graphene oxide solution;

[0060] 5) Submerge the SLZ-coated magnesium alloy sampl...

Embodiment 3

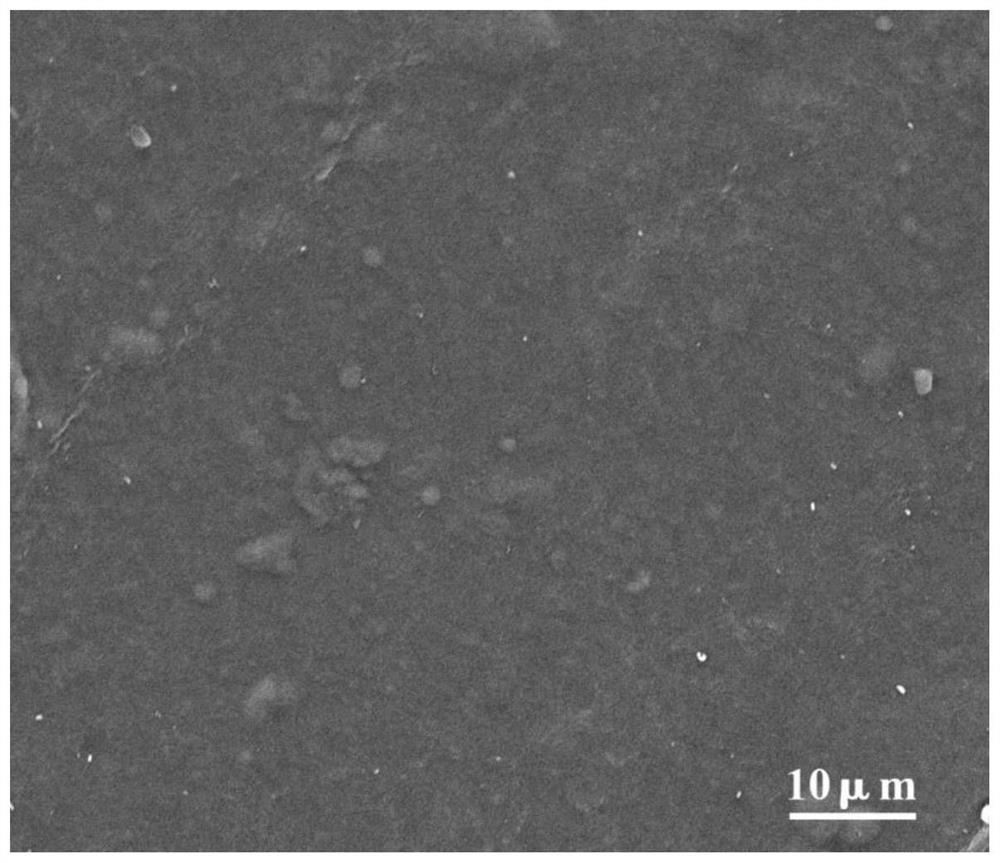

[0063] 1) Prepare calcium hydrogen phosphate dihydrate coating (abbreviated as DCPD coating) on the surface of the magnesium alloy substrate by electrodeposition method, and refer to "Enhanced corrosion resistance and antibacterial property of Zndoped DCPD coating on biodegradable Mg" for detailed preparation process, and put it into Dry in a vacuum oven at 60°C for 12 hours;

[0064] 2) Prepare a 1 mg / mL graphene oxide aqueous solution, ultrasonically disperse for 2 hours, and prepare a graphene oxide dispersion;

[0065] 3) Put 0.1g of chitosan into 10mL of distilled water, add 0.1mL of glacial acetic acid, stir with a magnetic stirrer for 24 hours until the chitosan is completely dissolved, and prepare an aqueous solution of chitosan;

[0066] 4) Take 1 mL of the dispersed graphene oxide solution and slowly add it to the chitosan solution, and use a magnetic stirrer and ultrasonic waves alternately until a uniformly dispersed chitosan / graphene oxide solution is formed;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com