Polypyrrole-coated ferroferric oxide nanoflower wave-absorbing material as well as preparation method and application thereof

A technology of ferroferric oxide and wave-absorbing materials, which is applied in the field of wave-absorbing materials, can solve problems such as the lack of synergistic effect of wave-absorbing agents, multiple loss mechanisms, and difficulty in meeting reflection loss capabilities, so as to promote multiple reflections and scattering, and prolong electromagnetic waves. The transmission path and dielectric loss are significantly enhanced by the effect of capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

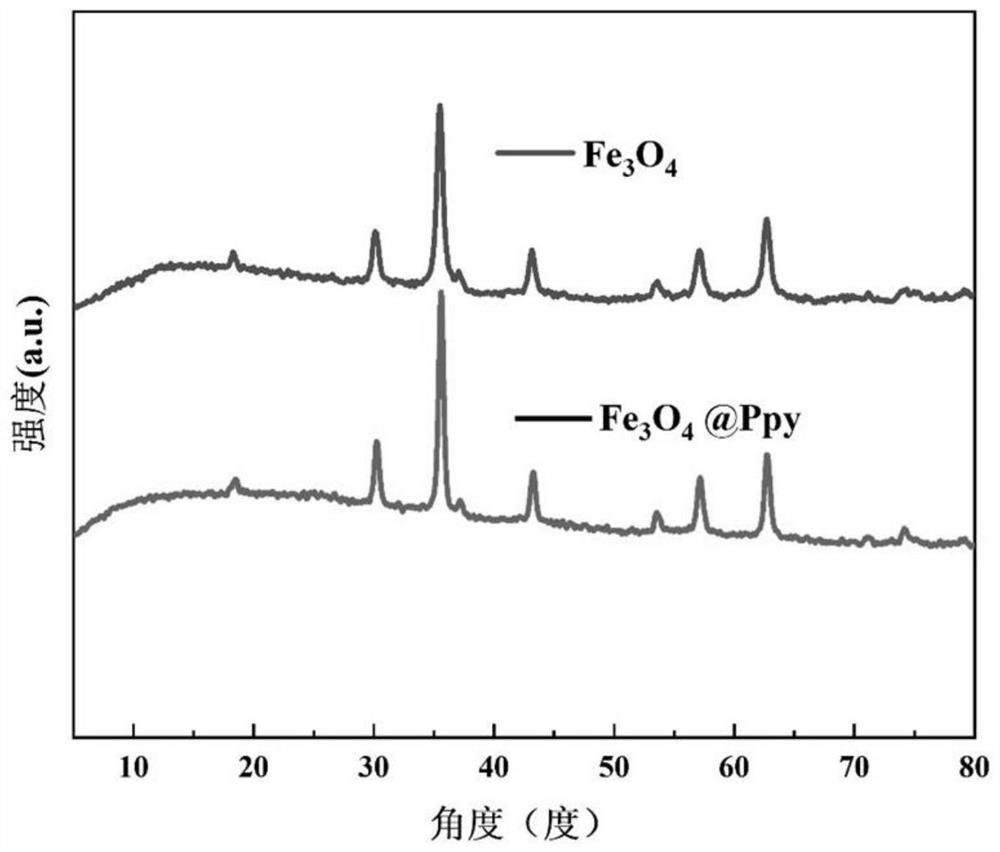

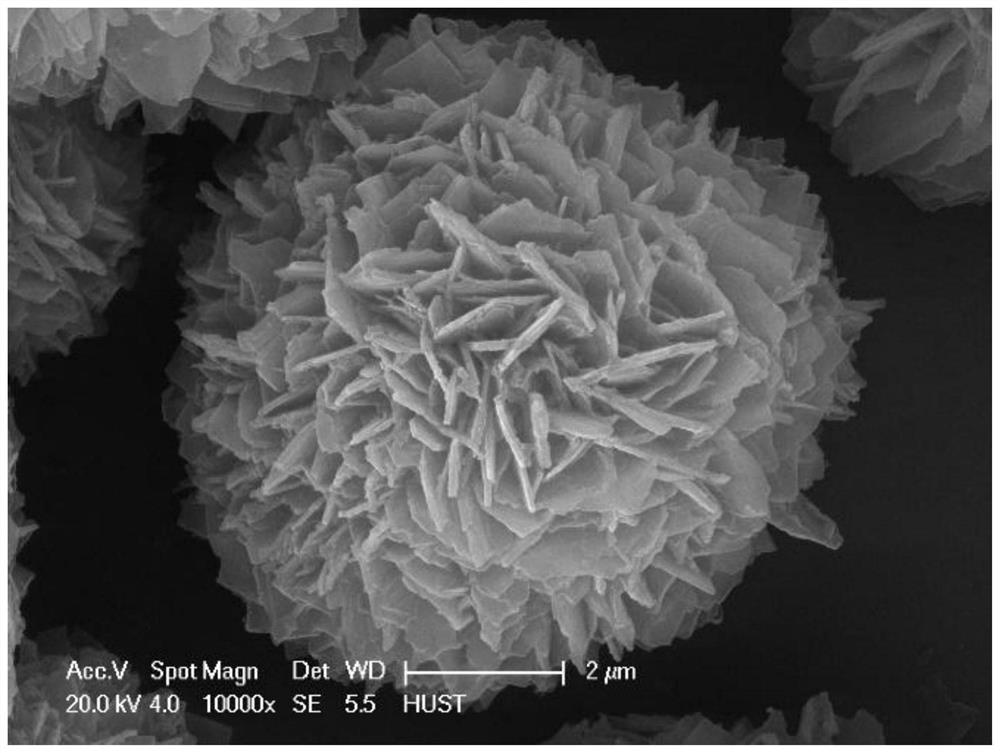

[0038] The invention provides a preparation method of a polypyrrole-coated iron ferric oxide nano flower absorbing material, comprising: S1: dissolving an inorganic ferric salt in an organic alcohol solvent, adding an alkaline substance to obtain a mixed solution, and dissolving The mixed solution is heated to 160-200 DEG C and kept warm for 2-6 hours to obtain a precursor with a hierarchical nanoflower structure; the precursor is ferric alkoxide.

[0039] S2: Calcining the precursor to obtain ferric iron tetroxide with a hierarchical nanoflower structure.

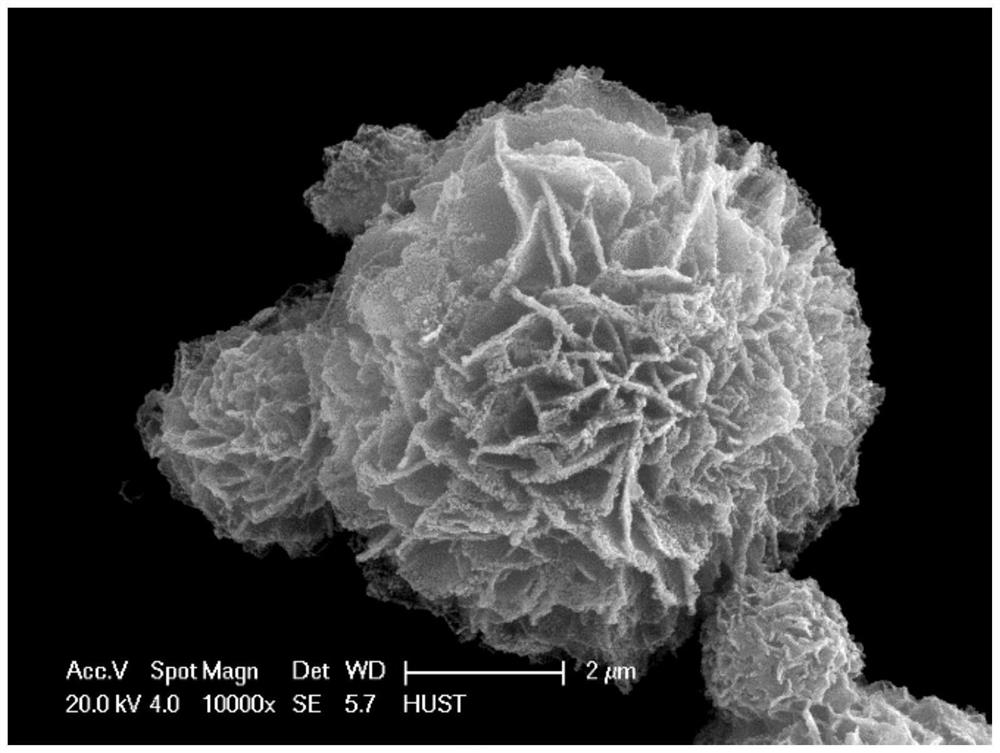

[0040] S3: Disperse the ferric oxide in deionized water, add pyrrole, and then add an oxidizing agent, so that the free radicals of the pyrrole cations are coupled and polymerized along the surface of the ultrathin sheet to obtain polypyrrole-coated ferric oxide nano-flowers wave material.

[0041] The principle of the above-mentioned preparation process is as follows:

[0042] Organic alcohols and iron ions are chelated t...

Embodiment 1

[0045] This embodiment includes the following preparation steps:

[0046] (1) Use anhydrous ferric chloride (FeCl 3 ) as a raw material, the precipitating agent is urea, and ethylene glycol is used as a solvent. The molar ratio of the above-mentioned anhydrous ferric chloride and urea is 1:8, and ultrasonically dissolve in 40mL of ethylene glycol for 40 minutes. Subsequently, the yellow solution was quickly transferred to a polytetrafluoroethylene-lined reactor with a volume of 100ml, and the program was set to raise the temperature to 200°C at a rate of 5°C / min for 4 hours. After the reaction program was completed, it was naturally cooled to room temperature. . The precipitate was collected by high-speed centrifugation, and washed three times with absolute ethanol and deionized water respectively, at a rotation speed of 12000 rpm, for four minutes each time. The centrifuged pellet was lyophilized for 12 hours.

[0047] (2) The precipitate obtained by freeze-drying was pas...

Embodiment 2-7

[0054] Examples 2-7 were prepared in the same manner as Example 1, see Table 1 for the differences.

[0055] The preparation process parameter table of table 1 embodiment 2-7

[0056]

[0057]

[0058] All of the above examples can obtain the polypyrrole-coated ferric oxide nanoflower absorbing material, and all exhibit good electromagnetic wave absorbing effects. Specifically, the electromagnetic wave absorption performance results are shown in Table 2 below:

[0059] The electromagnetic wave absorption performance of table 2 embodiment 2-7

[0060] Thickness (mm) Frequency range of reflectivity RL≤-10dB (GHz) Example 2 2mm 14(GHz)-17(GHz) Example 3 2.3mm 13.2(GHz)-16.7(GHz) Example 4 1.75mm 13.7(GHz)-18(GHz) Example 5 2mm 15.6(GHz)-18(GHz) Example 6 5mm 4.8(GHz)-7.2(GHz) Example 7 1.75mm 12.9(GHz)-18(GHz)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com