Electroplating chromium-containing wastewater resourceful treatment method based on interface coordination regulation and control

A treatment method and technology for chromium wastewater, applied in the environmental field, can solve the problems of being easily poisoned by heavy metals, high production cost, large amount of precipitation, etc., and achieve the effects of resource treatment, low production cost, and high chromium removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

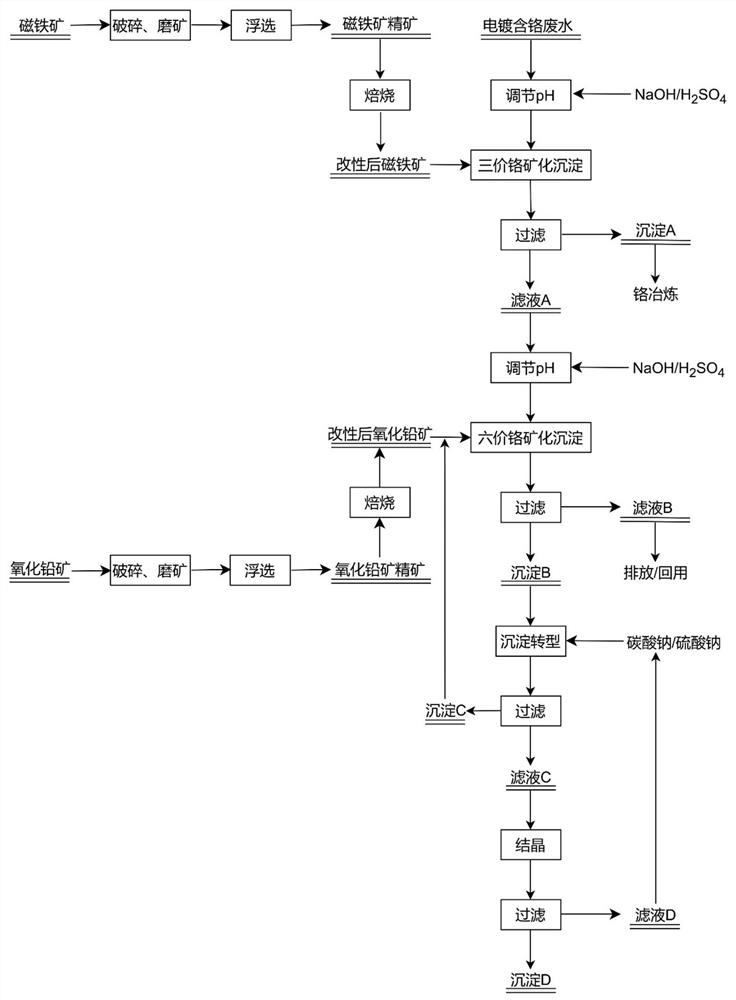

[0036] A resourceful treatment method for electroplating chromium-containing wastewater based on interface coordination regulation, such as figure 1 shown, including the following steps:

[0037] The pH of an electroplating wastewater is 7.3, the total chromium concentration is 100mg / L, and the hexavalent chromium concentration is 92mg / L. Take 250mL of the waste water, adjust the pH value to 2.7, add 0.006g of modified magnetite, stir and react for 30min, and then filter. Add modified lead oxide powder to the filtrate according to twice the stoichiometric number of chromate and lead ions, stir and grind for 120 minutes, let it stand for 30 minutes, and the total chromium concentration in the filtrate is reduced to 0.18 mg / L after filtration, and the concentration of hexavalent chromium down to 0.05mg / L, all reaching the discharge standard of electroplating wastewater. The filtered precipitate is mainly composed of lead oxide ore and chrome-lead ore after detection. Dilute wi...

Embodiment 2

[0039] A resourceful treatment method for electroplating chromium-containing wastewater based on interface coordination regulation, such as figure 1 shown, including the following steps:

[0040]The pH of electroplating chromium-containing wastewater from a factory in Suzhou, Jiangsu Province is 4.8, the total chromium content is 416mg / L, and the hexavalent chromium content is 321mg / L. Take 1L of the wastewater, adjust the pH to 2.5, and add 0.285g of modified maghemite. After stirring and reacting for 30 minutes, it is filtered, and the filter residue is composed of chromite and magnetite, which can be recovered as ore blending for smelting chromium. Adjust the pH of the filtrate to 3.0, add the modified lead oxide powder according to 3 times the stoichiometric number of chromate and lead ions, stir and grind for 120 minutes, let stand for flocculation and precipitation, and the total chromium concentration in the supernatant after precipitation is reduced to 0.20mg / L, the ...

Embodiment 3

[0042] A resourceful treatment method for electroplating chromium-containing wastewater based on interface coordination regulation, such as figure 1 shown, including the following steps:

[0043] The pH of electroplating chromium-containing wastewater from a factory in Nanjing, Jiangsu Province is 2.7, the total chromium content is 382mg / L, and the hexavalent chromium content is 267mg / L. Take 1L of the waste water, without adjusting the pH, directly add 0.345g of modified maghemite, stir and react for 30 minutes, and then filter. Adjust the pH value of the filtrate to 3.5, add 4g of modified lead oxide powder, stir and grind for 120min, let it stand for precipitation, after precipitation, the total chromium concentration in the supernatant drops to 0.2mg / L, and the hexavalent chromium concentration drops to 0.05mg / L, all meet the discharge standard of electroplating wastewater. The precipitate produced after filtration is introduced into the transformation tank, diluted wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com