Method for producing electrolytic manganese by using low-grade manganese oxide three-ore method

A manganese oxide, low-grade technology, applied in the electrolysis process, electrolysis components, photography technology, etc., can solve the problems of slow leaching speed, system acid expansion, low manganese leaching recovery rate, etc., to achieve pollution elimination, high recovery rate, leaching short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

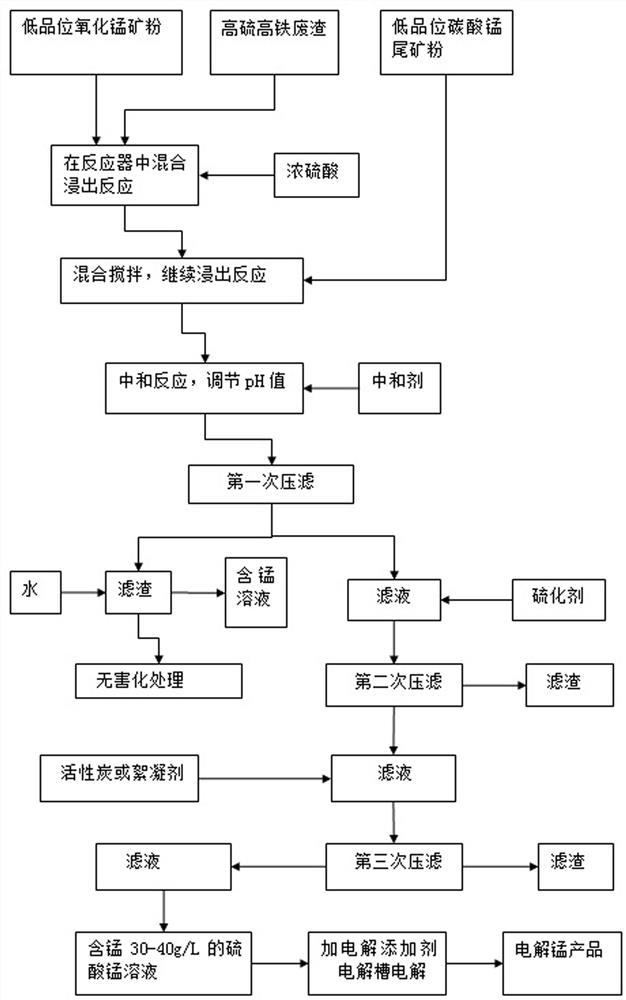

Image

Examples

Embodiment 1

[0044] A method for producing electrolytic manganese by a low-grade manganese oxide three-mineral method, comprising the following process steps:

[0045](1) According to the ratio of the three mines, the raw material of manganese oxide ore powder: high-sulfur and high-iron waste slag: the mass ratio of low-grade manganese carbonate tailings is 6.5:2.5:1, and 20% manganese oxide by weight is added to the reactor The following low-grade manganese oxide ore powder raw materials are mixed with high-sulfur and high-iron waste slag, the high-sulfur and high-iron waste slag is the sulfur-containing iron waste slag left by the selection of lead-zinc ore; For 3 hours, the amount of concentrated sulfuric acid to be added is calculated based on the manganese content in the added low-grade manganese oxide ore powder raw material and the iron content in the high-sulfur and high-iron waste slag and the concentrated sulfuric acid. Mix and stir the low-grade manganese carbonate tailings powd...

Embodiment 2

[0050] A method for producing electrolytic manganese by a low-grade manganese oxide three-mineral method, comprising the following process steps:

[0051] (1) Add low-grade manganese oxide ore powder raw materials containing less than 20% manganese oxide weight content and high-sulfur and high-iron waste slag into the reactor, add concentrated sulfuric acid with a mass content of 98% for redox leaching reaction for 3.5 hours, and the concentration of concentrated sulfuric acid The addition amount is calculated based on the manganese content in the added low-grade manganese oxide ore powder raw material and the iron content in the high-sulfur and high-iron waste slag reacting with the concentrated sulfuric acid in accordance with the stoichiometric ratio; Mix and stir the low-grade manganese carbonate tailings powder, and continue the leaching reaction for 2.5 hours; after the leaching reaction, add 8% ammonia water to the solution, adjust the pH value to 6.5, remove iron, silic...

Embodiment 3

[0056] A method for producing electrolytic manganese by a low-grade manganese oxide three-mineral method, comprising the following process steps:

[0057] (1) Add low-grade manganese oxide ore powder raw materials containing less than 20% manganese oxide weight content and high-sulfur and high-iron waste slag into the reactor, add concentrated sulfuric acid with a mass content of 98% to carry out redox leaching reaction for 4 hours, the concentration of concentrated sulfuric acid The addition amount is calculated based on the manganese content in the added low-grade manganese oxide ore powder raw material and the iron content in the high-sulfur and high-iron waste slag reacting with the concentrated sulfuric acid in accordance with the stoichiometric ratio; Mix and stir the low-grade manganese carbonate tailings powder, and continue the leaching reaction for 2 hours; after the leaching reaction, add neutralizing agent calcium carbonate powder and ammonia water to the solution, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com