Preparation method and device of sulfur tetrafluoride

A technology for preparing sulfur tetrafluoride, which is applied in the direction of carbon fluoride, sulfur and halogen compounds, etc., can solve the problem of high added value of by-products, and achieve the effects of active chemical reaction, accelerated reaction rate, and lower reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

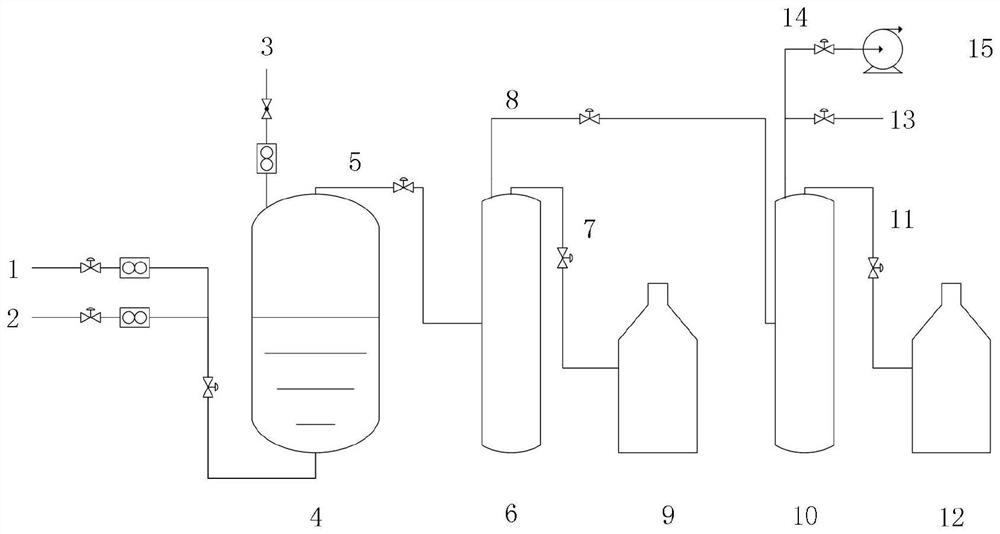

[0035] Such as figure 1 As shown, the preparation device of sulfur tetrafluoride in this embodiment includes a fluorination reactor 4, the bottom of the fluorination reactor 4 is connected with a fluorine gas pipeline 1 and an inert gas pipeline 2, and the top of the fluorination reactor 4 passes through Connecting pipeline one 5 is connected to cryogenic collector I6, the top of said low-temperature collector I6 is connected to sulfur tetrafluoride storage tank 9 through connecting pipeline two 7, and said low-temperature collector I6 is connected to low-temperature collector II10 through connecting pipeline three 8 , the top of the low-temperature collector II10 is connected to the carbon tetrafluoride storage tank 12 through the connecting pipe IV11; the top of the fluorination reactor 4 is connected to the liquid inlet pipe 3, and the top of the low-temperature collector II10 is connected to the emptying pipe , the evacuation pipeline includes a normal pressure evacuation ...

Embodiment 2

[0040] Adopt the preparation device in the embodiment 1 to prepare the method for sulfur tetrafluoride, may further comprise the steps:

[0041] S1, first adopt vacuum pump 15 to carry out vacuum pretreatment to each part of device; Then use argon to purge and replace the residual air and moisture in the system; carbon disulfide is input in the fluorination reactor 4 through the liquid inlet pipeline 3, and the fluorine Gas and argon are passed into the fluorination reactor 4 at a volume ratio of 1:9, the operating pressure of the fluorination reactor 4 is set to -0.05MPa, and the reaction is carried out at a temperature of 20°C to obtain the initial product;

[0042] S2. Pass the primary product obtained in S1 into the low-temperature collector I6, set the operating pressure of the low-temperature collector I6 to be -0.09MPa, and obtain light exhaust gas and liquefied tetrafluoroethylene at a temperature of -110°C Sulfur tetrafluoride, the sulfur tetrafluoride liquefied in th...

Embodiment 3

[0047] Adopt the preparation device in the embodiment 1 to prepare the method for sulfur tetrafluoride, comprise the steps:

[0048] S1, first use the vacuum pump 15 to carry out vacuum pretreatment on each part of the device; then use nitrogen to purge and replace the residual air and moisture in the system; enter the mixed solution of carbon disulfide and sulfur into the fluorination reactor 4 through the liquid inlet pipe 3 In the process, fluorine gas and nitrogen gas are passed into the fluorination reactor 4 with a volume ratio of 1:24, the operating pressure of the fluorination reactor 4 is set to -0.03MPa, and the reaction is performed at 30°C to obtain the initial product; The mass ratio of sulfur and carbon disulfide in the mixture of carbon disulfide and sulfur is 1:0.8;

[0049] S2. Pass the primary product obtained in S1 into the low-temperature collector I6, set the operating pressure of the low-temperature collector I6 to -0.05MPa, and obtain light exhaust gas a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com