Functional water-based anti-flash-rust agent and preparation method thereof

An anti-flash rust agent and functional technology, applied in anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve problems such as slow volatilization speed, easy rusting of metal substrates, poor anti-flash rust effect, etc., to achieve Effect of lowering surface tension, enhancing adhesion and corrosion resistance, improving flash rust prevention and corrosion inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

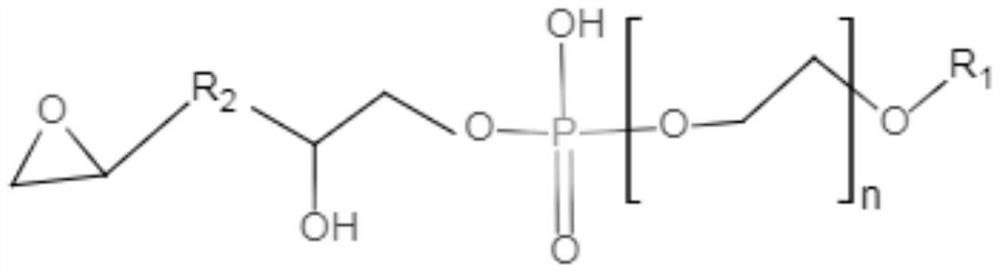

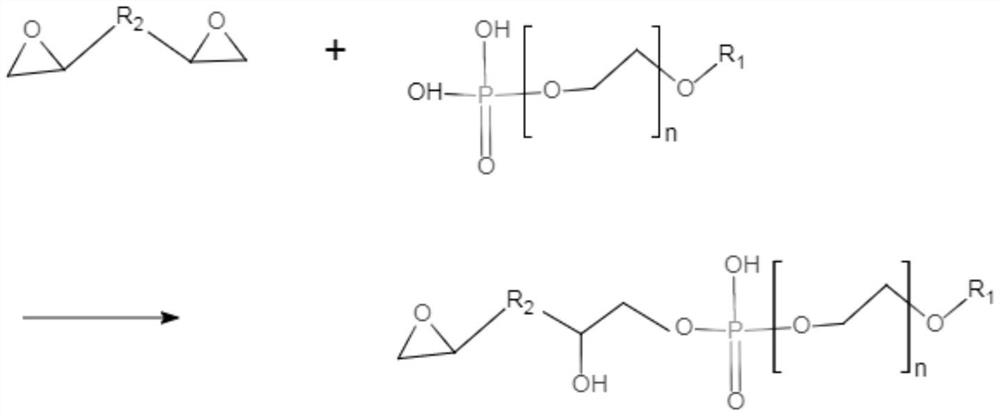

Image

Examples

Embodiment 1

[0028] (1) Mix 0.1 mol of dehydrated oleic acid polyoxyethylene ether phosphate with 300 ml of toluene, add 0.2 g of boron trifluoride etherate complex, and stir and add 0.1 mol of ethylene glycol dishrinkle Glyceryl ether, the reaction temperature is controlled at 85°C, and the intermediate 1 is obtained after 30 minutes of reaction;

[0029] (2) Add 0.2mol diethanolamine, react at 80°C for 60min to obtain main active compound 2;

[0030] (3) Distill out the organic solvent, cool down to 60°C, stir and add 0.15mol morpholine and deionized water, add deionized water according to the solid content of 80%, keep warm for 3-10h, filter the material, and obtain the function of phosphate group Type water-based anti-flash rust product.

[0031] (4) the water-based anti-flash rust agent prepared by the present invention is added in the water-based epoxy coating, and the addition is 1.5%, and the coating is sprayed on the cast iron surface afterwards, and is sprayed with the coating t...

Embodiment 2

[0034] Basically the same as Example 1, the difference is that the following steps are also included between steps (1) and (2): add 0.03mol oxalic acid and 0.005mol p-toluenesulfonic acid to intermediate 1, and react at 80°C for 120min; Carry out the reaction in step (2) again.

Embodiment 3

[0036] (1) Mix 0.1 mol of dehydrated octylphenol polyoxyethylene ether phosphate with 300 ml of dioxane, add 0.2 g of ammonium persulfate, and stir and add 0.08 mol of 1,4-butanediol under the condition of keeping warm at 55°C Diglycidyl ether, the reaction temperature is controlled at 110°C, and the intermediate 1 is obtained after 40 minutes of reaction;

[0037] (2) Add 0.025mol succinic acid and 0.005mol p-toluenesulfonic acid to intermediate 1, react at 110°C for 30min;

[0038] (3) Add 0.2mol monoethanolamine, react at 40°C for 120min to obtain main active compound 2;

[0039] (4) distill off the organic solvent, lower the temperature to 60°C, stir and add 0.15mol tolylbenzotriazole and deionized water, add the deionized water according to the solid content of 25%, keep warm for 3-10h, filter and discharge the material, and obtain Phosphate-based functional water-based anti-flash rust agent product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com