Bipolar current collector modified by self-repairing conductive coating as well as preparation method and application of bipolar current collector

A technology of conductive coating and current collector, which is applied in the field of bipolar current collector and its preparation, can solve problems such as electrolyte leakage, seepage, battery short circuit, etc., to prevent internal short circuit, prevent penetration, and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a method for preparing a bipolar current collector modified by a self-repairing conductive coating, comprising the following steps:

[0037] Preparation of microcapsules containing repairing agent;

[0038] preparing a slurry containing the microcapsules, catalyst, binder and conductive filler;

[0039] The slurry is coated on the surface of the current collector substrate to obtain a self-healing conductive bipolar current collector with coating.

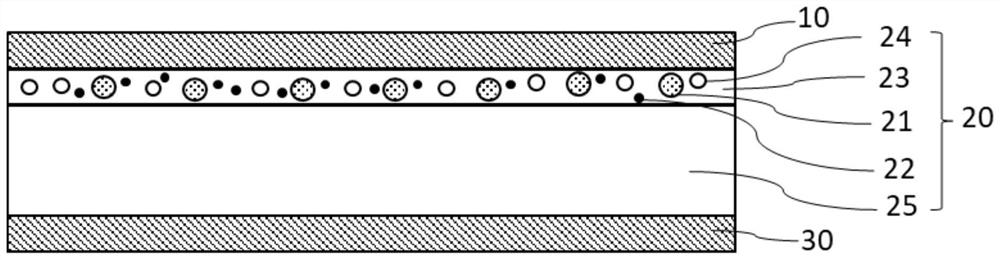

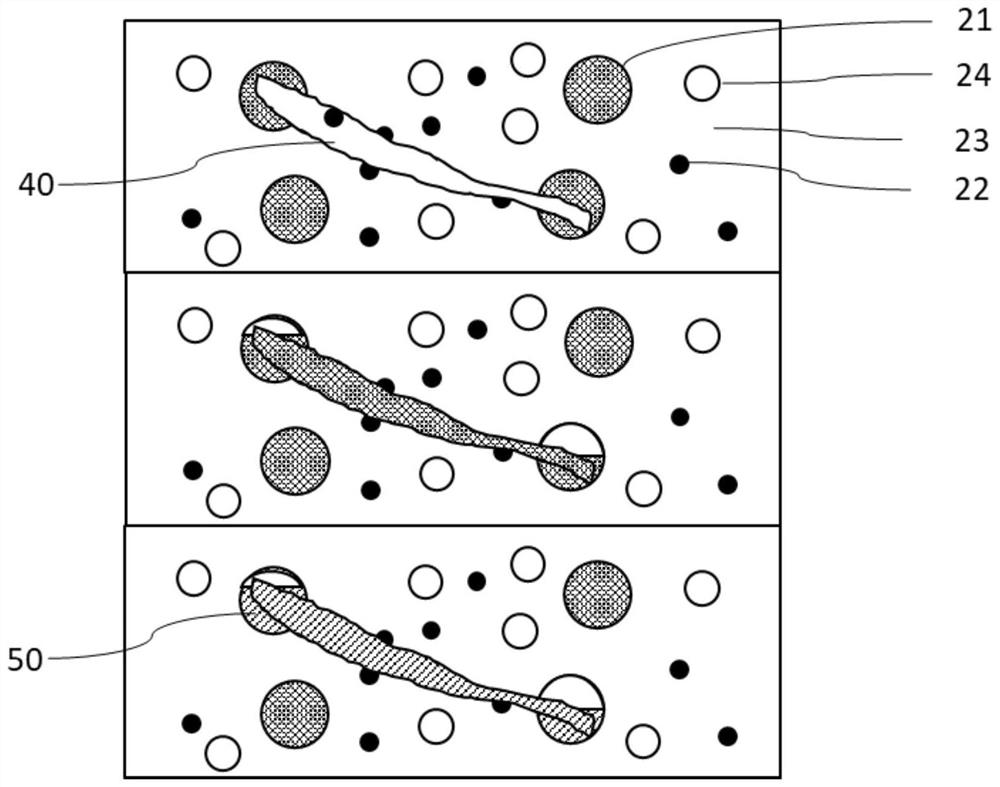

[0040] The structure of the bipolar current collector prepared by this preparation method is as follows: figure 1 As shown, it includes a positive electrode material layer 10, a current collector layer 20, and a negative electrode material layer 30 from top to bottom. The current collector layer 20 includes a current collector matrix 25 and a self-healing conductive coating. Capsule 21, catalyst 22, binder 24 and conductive agent 23. figure 2 is a schematic diagram of the self-healing process of th...

Embodiment 1

[0052] This embodiment provides a self-healing conductive bipolar current collector, the current collector includes an aluminum foil and a self-healing conductive coating, and the self-healing conductive coating is coated on both sides of the aluminum foil. The self-healing conductive coating consists of phenylisocyanate / bisphenol A epoxy resin microcapsules, dibutyltin dilaurate catalyst, polyethylene and titanium powder. The preparation method of the self-repairing conductive bipolar current collector comprises the following steps:

[0053] Synthesis of 4,4'-methylenebis(phenylisocyanate) / dicyclopentadiene self-healing microcapsules by interfacial polymerization;

[0054] Weigh 20 parts of 4,4'-methylene bis(phenyl isocyanate) / bisphenol A epoxy resin microcapsules, 5 parts of dibutyltin dilaurate sodium catalyst catalyst, 5 parts of polyethylene and 50 parts of titanium powder Adding to the toluene solution in turn, every time one material is added to the solvent, it must b...

Embodiment 2

[0060] This embodiment provides a self-healing conductive bipolar current collector, the current collector includes a copper foil and a self-healing conductive coating, and the self-healing conductive coating is coated on the surface of the copper foil on one side. The self-healing conductive coating is composed of urea-formaldehyde resin / dicyclopentadiene microcapsules, Grubbs catalyst, nitrile rubber and carbon black. The preparation method of the self-repairing conductive bipolar current collector comprises the following steps:

[0061] Synthesis of urea-formaldehyde resin / dicyclopentadiene self-healing microcapsules by in situ polymerization:

[0062] Weigh 5 parts of urea-formaldehyde resin / dicyclopentadiene microcapsules, 0.1 part of Grubbs catalyst, 5 parts of nitrile rubber and 30 parts of carbon black and add them to the toluene solution in turn, and stir evenly when adding a material to the solvent Then add another material to finally get a uniform and stable slurry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Coating thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com