Porous ceramic and preparation method thereof

A technology of porous ceramics and ceramic embryos, which is applied to ceramic products, other household utensils, and household utensils. It can solve the problems of large pore size, easily affected stability of porous ceramics, and low thermal conductivity, so as to improve adsorption performance and equipment. Low requirements, the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

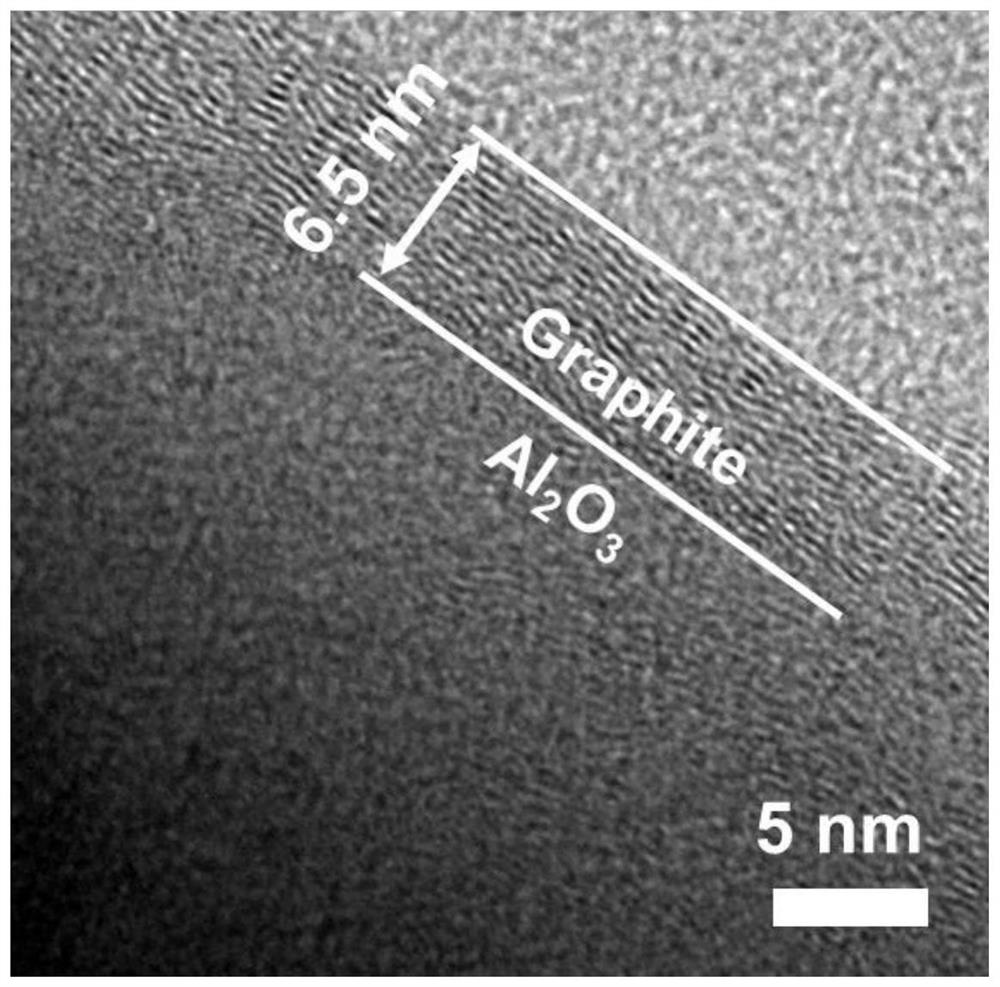

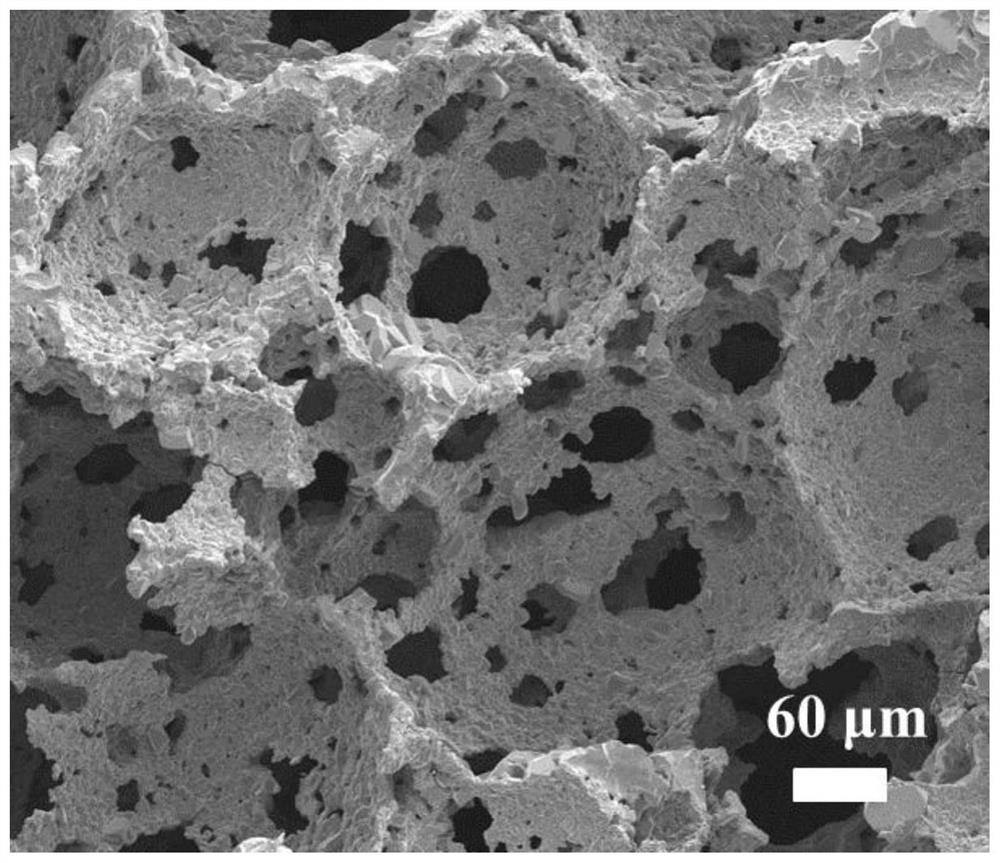

[0042] Put 50g of alumina particles, 10g of sucrose, and 1.5g of ammonium polyacrylate in 100mL of deionized water and stir evenly at room temperature; then add n-hexylamine solution (n-hexylamine 1.5g, ethanol 2mL) dropwise under stirring to make a dispersion , the dropping rate is 2mL / min; add 100mL n-hexane to the prepared dispersion liquid, foam with a hand-held mixer, the stirring rate is 15000rpm, and the stirring time is 3min to form a stable Pickering emulsion; the above-mentioned Pickering emulsion is dried at room temperature and placed Put it into the quartz tube of the tube furnace, fill the system with argon gas, the flow rate of argon gas is 10-20mL / min, so that there is no active gas such as oxygen in the quartz tube. The Pickering foam was heated at a rate of 10°C / min to the final carbonization temperature of 1500°C, and kept at this temperature for 3 hours. Slowly lower the temperature under argon to obtain a porous alumina ceramic, marked as C1.

[0043] For...

Embodiment 2

[0046] Put 60g of alumina particles, 18g of sucrose, and 2g of ammonium polyacrylate in 100mL of deionized water and stir evenly at room temperature; then add propyl gallate solution dropwise under stirring (2g of propyl gallate, 2mL of ethanol) to prepare Dispersion, drop rate 2mL / min; Add 150mL n-dodecane to the prepared dispersion, foam with a hand-held mixer, stirring speed 15000rpm, stirring time 3min, to form a Pickering emulsion with stable particles; the Pickering emulsion above After drying at room temperature, put it into the quartz tube of the tube furnace, fill the system with argon gas, and the flow rate of argon gas is 10-20mL / min, so that there is no active gas such as oxygen in the quartz tube. The ceramic green body was heated at a rate of 10°C / min to a final carbonization temperature of 1500°C, and kept at this temperature for 3 hours. Slowly lower the temperature under argon to obtain porous alumina ceramics, marked as C2.

[0047] The average pore diameter...

Embodiment 3

[0049] Put 40 g of alumina particles, 15 g of starch, and 1 g of ammonium polyacrylate into 100 mL of deionized water and stir evenly at room temperature; Methyl ammonium bromide 1g, water 2mL) make dispersion liquid, drop rate 1mL / min; Add 200mL n-hexane in the dispersion liquid made, and foam with hand-held mixer, stirring rate 15000rpm, stirring time 3min, form Particle-stabilized Pickering emulsion; the above-mentioned stable Pickering emulsion is put into the quartz tube of the tube furnace after drying at room temperature, and the system is filled with argon gas, the flow rate of argon gas is 10-20mL / min, so that there is no active gas such as oxygen in the quartz tube . The ceramic green body was heated at a rate of 10°C / min to a final carbonization temperature of 1600°C, and kept at this temperature for 3 hours. Slowly lower the temperature under argon to obtain porous alumina ceramics, marked as C3.

[0050] The average pore diameter of the porous alumina ceramic pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com