Preparation method of nanocellulose hollow microspheres and coating material of nanocellulose hollow microspheres

A nano-cellulose, hollow technology, applied in the direction of coating, etc., can solve the problems of no public reports in the research, achieve good application prospects, increase the diffusion rate, and improve the dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

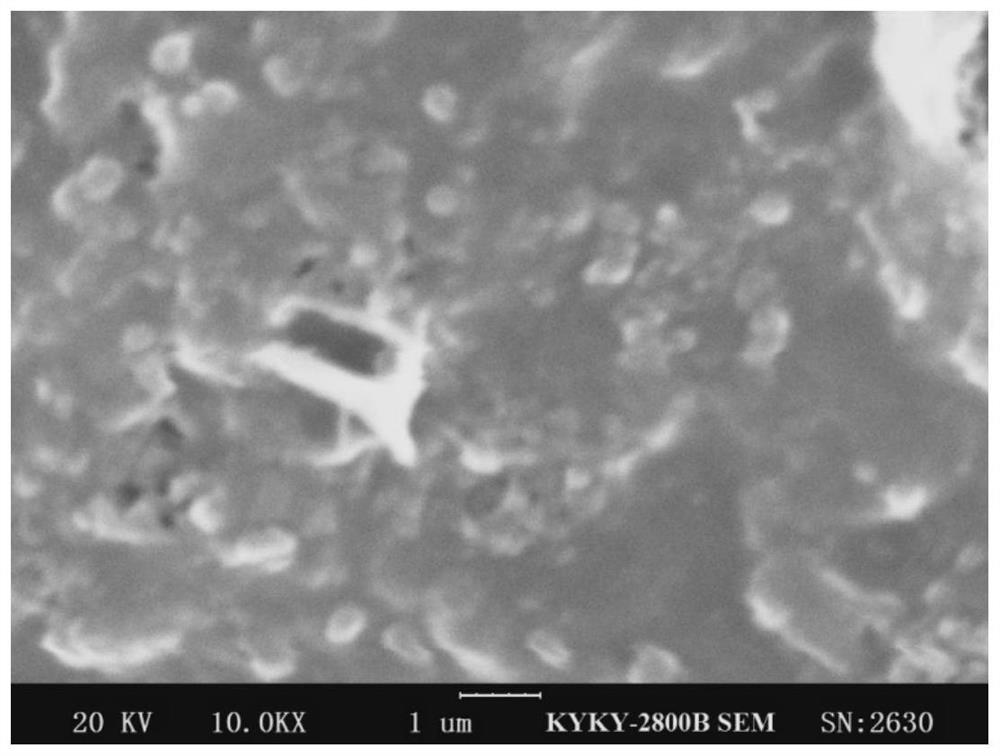

Image

Examples

preparation example Construction

[0025] The embodiment of the present invention provides a preparation method of nanocellulose hollow microspheres, comprising the following steps:

[0026] Step 1, the nanocellulose is subjected to esterification surface modification to obtain a modified nanocellulose Pickering emulsifier;

[0027] Step 2, dispersing the modified nanocellulose Pickering emulsifier into deionized water to obtain a modified nanocellulose aqueous solution;

[0028] In step 3, the modified nanocellulose aqueous solution is used as the water phase, and the mixed solution of dichloromethane and acrylate monomer is used as the oil phase, and the nanocellulose hollow microsphere composite material is obtained by the Pickering emulsion polymerization method.

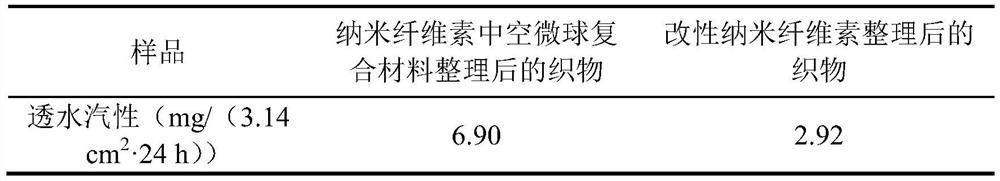

[0029] An embodiment of the present invention also provides a reinforced, toughened and highly air-permeable nanocellulose hollow microsphere coating material, which includes a nanocellulose hollow microsphere coating material and a film layer at...

Embodiment 1

[0033] 1) Preparation of modified nanocellulose Pickering emulsifier: prepare 70 parts of nanocellulose anhydrous pyridine solution, the mass concentration of nanocellulose anhydrous pyridine solution is 0.1g / mL, ultrasonic treatment for 10min, and then add it to a 100mL three-necked flask , add 30 parts of succinic anhydride, stir at room temperature for 6 hours, after the reaction, the modified nanocellulose is precipitated, then repeatedly washed with absolute ethanol, centrifuged, and then placed in a vacuum drying oven to constant weight to obtain a white Solid powder to prepare modified nano-cellulose Pickering emulsifier.

[0034] 2) Preparation of modified nanocellulose aqueous solution: Weigh 1 part of modified nanocellulose prepared in step 1, dissolve it in deionized water, and obtain modified nanocellulose aqueous solution; wherein, the mass concentration of modified nanocellulose solution 0.1g / mL.

[0035] 3) Preparation of nanocellulose hollow microsphere compos...

Embodiment 2

[0037] 1) Preparation of modified nanocellulose Pickering emulsifier: prepare 75 parts of nanocellulose anhydrous pyridine solution, the mass concentration of nanocellulose anhydrous pyridine solution is 0.1g / mL, ultrasonic treatment for 15min, and then add it to a 100mL three-necked flask , add 25 parts of acetic anhydride, and stir at room temperature for 8 hours. After the reaction, the nanocellulose after esterification modification is precipitated, then repeatedly washed with absolute ethanol, centrifuged, and then placed in a vacuum drying oven to constant weight to obtain a white The solid powder of esterified modified nanocellulose Pickering emulsifier was obtained.

[0038] 2) Preparation of modified nanocellulose aqueous solution: Weigh 1 part of modified nanocellulose prepared in step 1, dissolve it in deionized water, and obtain modified nanocellulose aqueous solution; wherein, the mass concentration of modified nanocellulose solution 0.1g / mL.

[0039]3) Preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com