Preparation method of hemp seed oil with high polyunsaturated fatty acid content

A technology of unsaturated fatty acids and hemp seed oil, which is applied in the direction of fat oil/fat refining and fat production, can solve the problems of polyunsaturated fatty acid enrichment and purification methods in hemp oil that have not yet been seen, and achieve good industrial preparation prospects. Enhanced nutritional and functional value, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

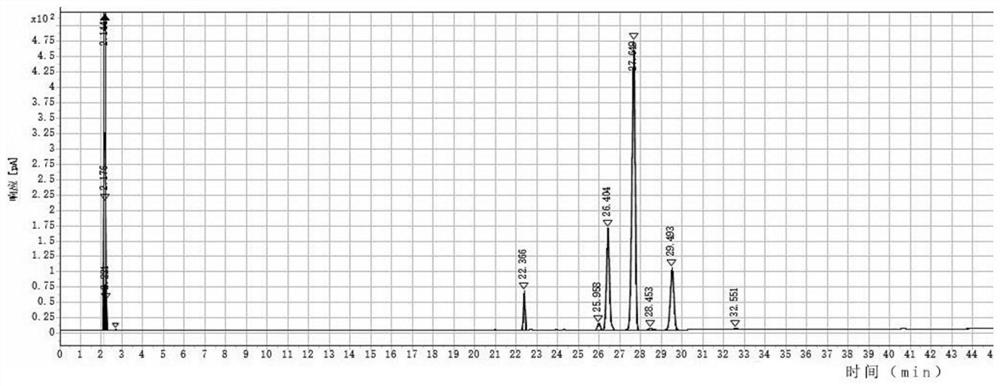

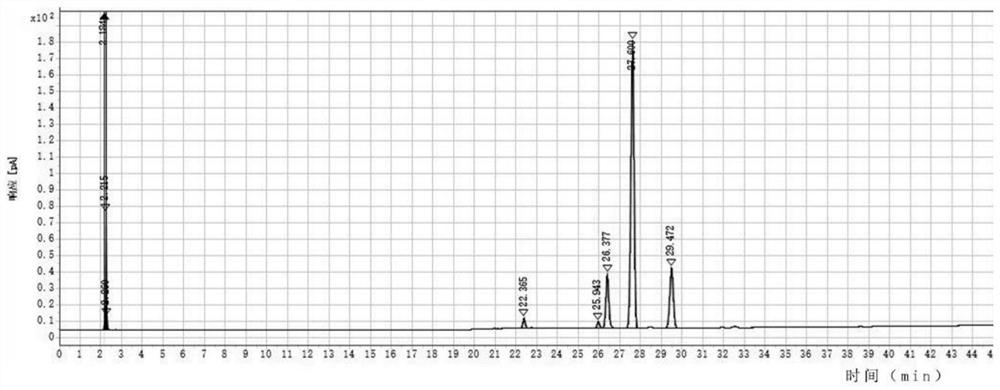

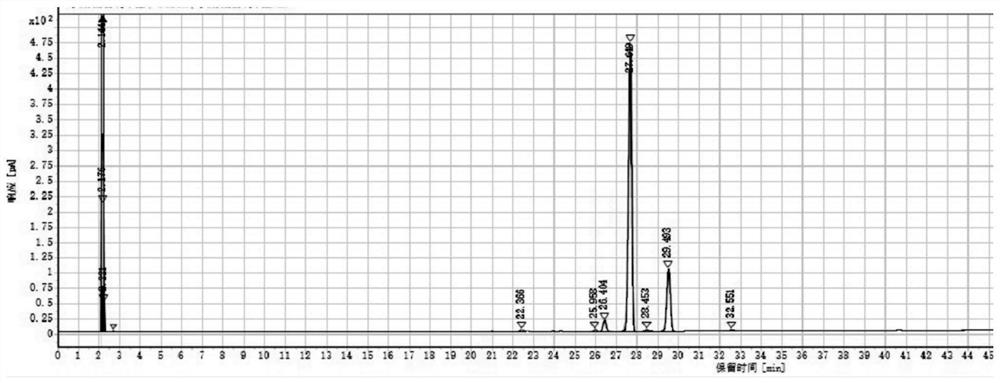

Image

Examples

Embodiment 1

[0112] Hemp seed oil with high unsaturated fatty acid content was prepared as follows.

[0113] ① Weigh 500g of sodium hydroxide, dissolve it in 30L of 90% ethanol (Vol%) to make a mixed solution, place it in a reaction kettle, put in 3kg of commercially available hemp oil raw material, keep the temperature at 70°C, stir for 30min, and perform the cracking reaction.

[0114]② After the cleavage reaction is completed, lower the temperature to 0°C, and solid fatty acid precipitation in the form of Na salt will appear. Continue to incubate for 30 minutes, stir evenly, put it into a centrifuge, centrifuge at 3000rpm, discard the ethanol test solution, -0.065MPa, 65°C Concentrate under reduced pressure to recover ethanol; the sodium fatty acid solid was rinsed twice with saturated saline, redissolved in water, adjusted to pH 2.0 with 6M hydrochloric acid, and separated completely after standing for 15 minutes. Back-extract twice, and completely separate the water phase to obtain 2....

Embodiment 2

[0118] Hemp seed oil with high unsaturated fatty acid content was prepared as follows.

[0119] ①Weigh 3kg of ammonium bicarbonate, dissolve it in 30L 60% acetone (Vol%) solution to make a mixed solution, put it in a reaction kettle, put into 10kg of oil leftovers produced by pressing hemp oil in the factory, keep the temperature at 40°C, stir for 120min, and carry out Crack.

[0120] ② After the cleavage reaction is completed, move to the concentration tank, concentrate under reduced pressure at -0.085MPa at 45°C, and recover acetone; return to the reaction kettle to cool down to room temperature, then stir while adjusting the pH to 4.0 with 6M phosphoric acid, and let it stand for 20 minutes to separate layers , take the fatty acid in the upper layer oil phase separately, back-extract three times with 15L pure water, and completely separate the water phase to obtain 9.58kg of fatty acid crude product oil;

[0121] ③Transfer the crude fatty acid oil above to a solid-phase ex...

Embodiment 3

[0125] Hemp seed oil with high unsaturated fatty acid content was prepared as follows.

[0126] ① Weigh 500g of potassium hydroxide, disperse it in 12L of n-heptane to make a mixed solution, place it in a reaction kettle, add 3kg of commercially available hemp oil, keep the temperature at 60°C, and fully stir for 60min to carry out cracking.

[0127] ② After the cleavage reaction is completed, move to the concentration tank, concentrate under reduced pressure at -0.075MPa at 60°C, and recover heptane; add 1L of purified water while it is hot, and return to the reactor to room temperature, then stir while adjusting the pH to 4.0, stand for 25 minutes to separate the layers, separate the fatty acid in the oil phase of the upper layer, back-extract three times with 6L pure water, completely separate the water phase, and obtain 2.78kg of crude fatty acid oil;

[0128] ③Transfer the crude fatty acid oil above to a solid-phase extraction column (8L, d:L=1:4) equipped with 3kg of dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com