Microporous carbon fiber material prepared from polyacrylonitrile and used for high-selectivity separation of various micromolecular gases, and preparation method and application of microporous carbon fiber material

A technology of polyacrylonitrile and fiber materials, applied in the field of microporous carbon fiber materials and its preparation, to achieve excellent industrial application prospects, good chemical stability and hydrothermal stability, and narrow pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

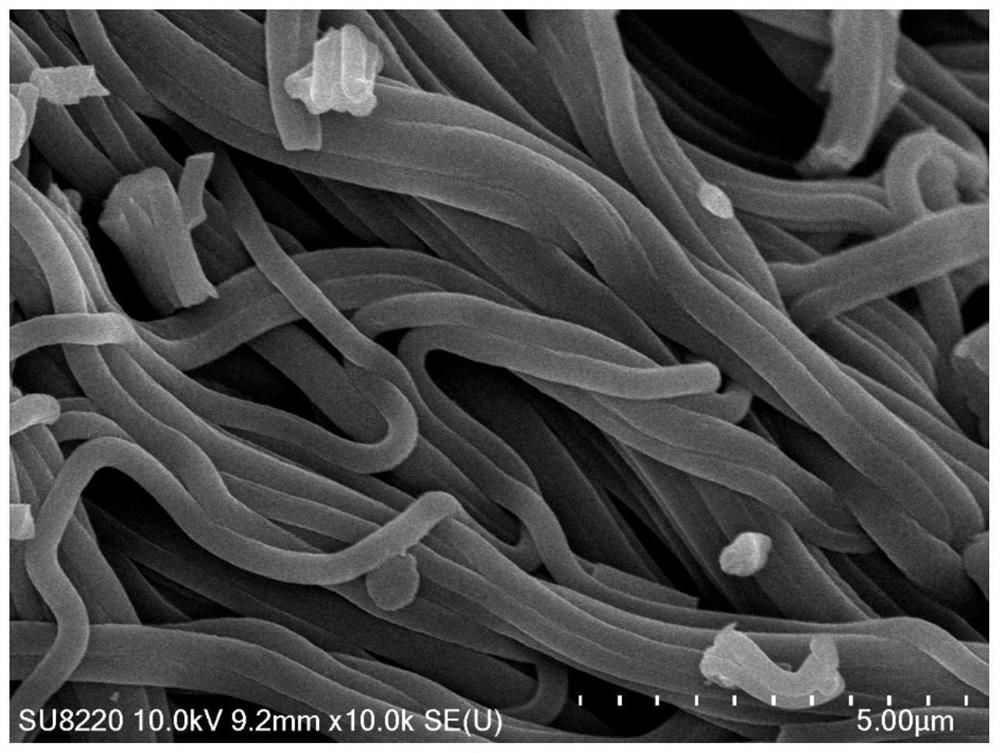

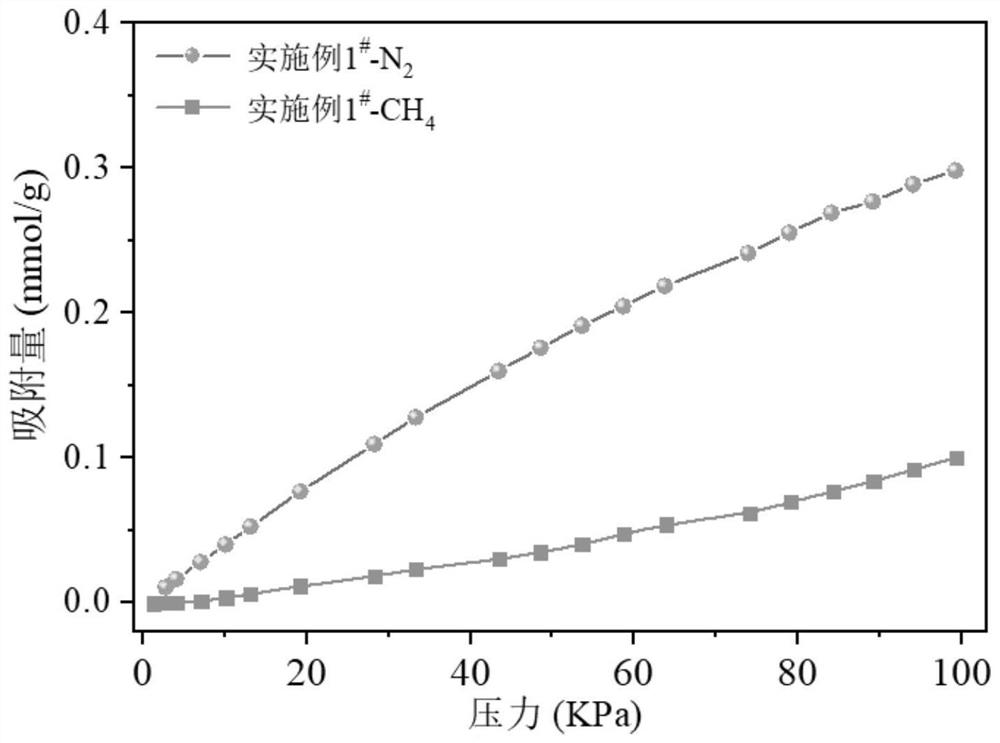

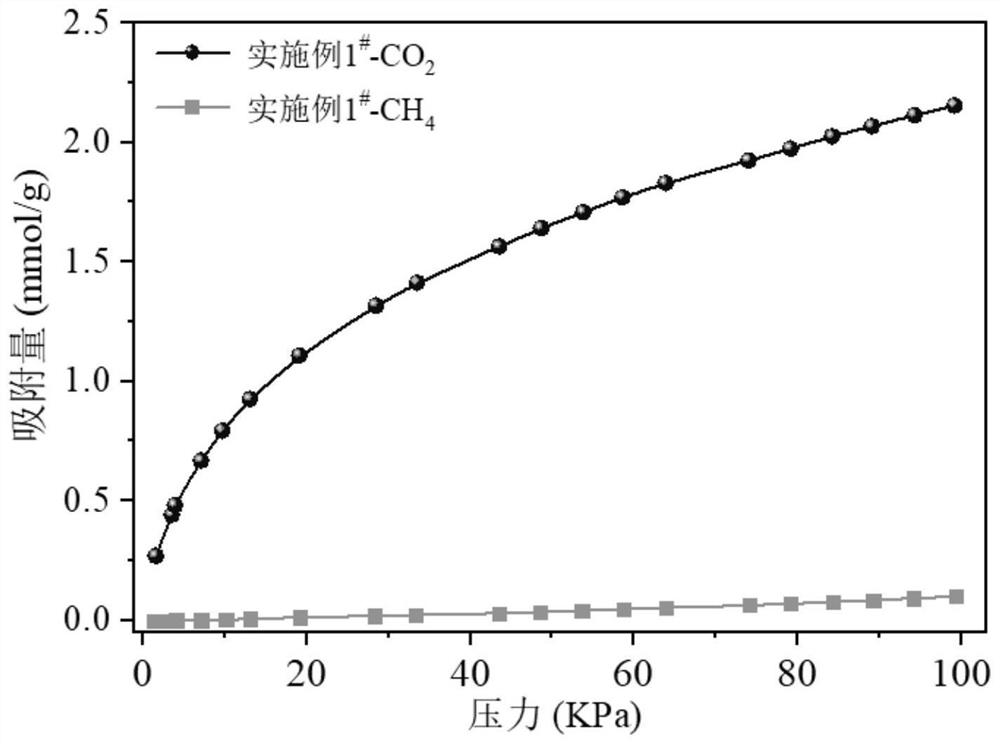

Embodiment 1

[0065] 1 g of polyacrylonitrile and 9 g of N,N-dimethylformamide were stirred and mixed at 40° C. for 24 h, and then 0.5 g of anhydrous zinc chloride was added. The mixed solution was stirred at 30°C under airtight conditions for 8 hours to make it uniformly dispersed. Then the mixed solution was subjected to electrospinning, the spinning voltage was 18KV, the injection rate was 1.0ml / h, the distance between the needle and the collector was 12cm, and the spinning time was 20h. After the polymer fibers obtained by spinning were dried at 150°C for 8 hours, 0.3 g was added to 25 ml of ethylene glycol, and while stirring at 130°C, 0.12 ml of ethylenediamine was added dropwise, reacted for 3 hours, and then suction-filtered to obtain crosslinked fibers. After the product is dried, put it in a porcelain boat, put it into a high-temperature tube furnace, and control the heating rate at 5°C / min under a nitrogen atmosphere. After rising to 800°C, perform an activation reaction for 1 ho...

Embodiment 2

[0067] 1 g of polyacrylonitrile and 9 g of N,N-dimethylformamide were stirred and mixed at 30° C. for 24 h, and then 0.5 g of anhydrous zinc chloride was added. The mixed solution was stirred at 30°C under airtight conditions for 8 hours to make it uniformly dispersed. Then the mixed solution was subjected to electrospinning, the spinning voltage was 20KV, the injection rate was 0.8ml / h, the distance between the needle and the collector was 10cm, and the spinning time was 20h. After drying the polymer fiber obtained by spinning at 130°C for 10 hours, take 0.5g and add it to 25ml of glycerol, while stirring at 135°C, add 0.25ml of 1,2-propylenediamine dropwise, react for 3 hours, and then filter with suction to obtain Cross-linked fibers. After the product is dried, put it in a porcelain boat, put it into a high-temperature tube furnace, and control the heating rate at 5°C / min under a nitrogen atmosphere. After rising to 800°C, perform an activation reaction for 1 hour to obta...

Embodiment 3

[0069] 1 g of polyacrylonitrile and 9 g of N,N-dimethylformamide were stirred and mixed at 30° C. for 24 h, and then 1.0 g of anhydrous zinc acetate was added. The mixed solution was stirred at 30°C under airtight conditions for 8 hours to make it uniformly dispersed. Then the mixed solution was subjected to electrospinning, the spinning voltage was 20KV, the injection rate was 0.8ml / h, the distance between the needle and the collector was 10cm, and the spinning time was 20h. After the polymer fibers obtained by spinning were dried at 120°C for 12 hours, 0.5 g was added to 25 ml of propylene glycol, and while stirring at 135°C, 0.4 ml of ethylenediamine was added dropwise, reacted for 3 hours, and suction filtered to obtain crosslinked fibers. After the product is dried, put it in a porcelain boat, put it into a high-temperature tube furnace, and control the heating rate at 5°C / min under a nitrogen atmosphere. After rising to 900°C, perform an activation reaction for 1 hour to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com