Method for synthesizing 2, 2-bis (4-hydroxy-3, 5-dimethylphenyl) propane by adopting microchannel reactor

A technology of microchannel reactor and dimethylphenyl, which is applied in chemical instruments and methods, preparation of organic compounds, chemical/physical/physicochemical processes, etc., can solve the problem of increasing discharge of waste liquid, waste gas and solid waste , long reaction time, poor practicability and other problems, to achieve the effect of safe, stable and controllable reaction process, short reaction time and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

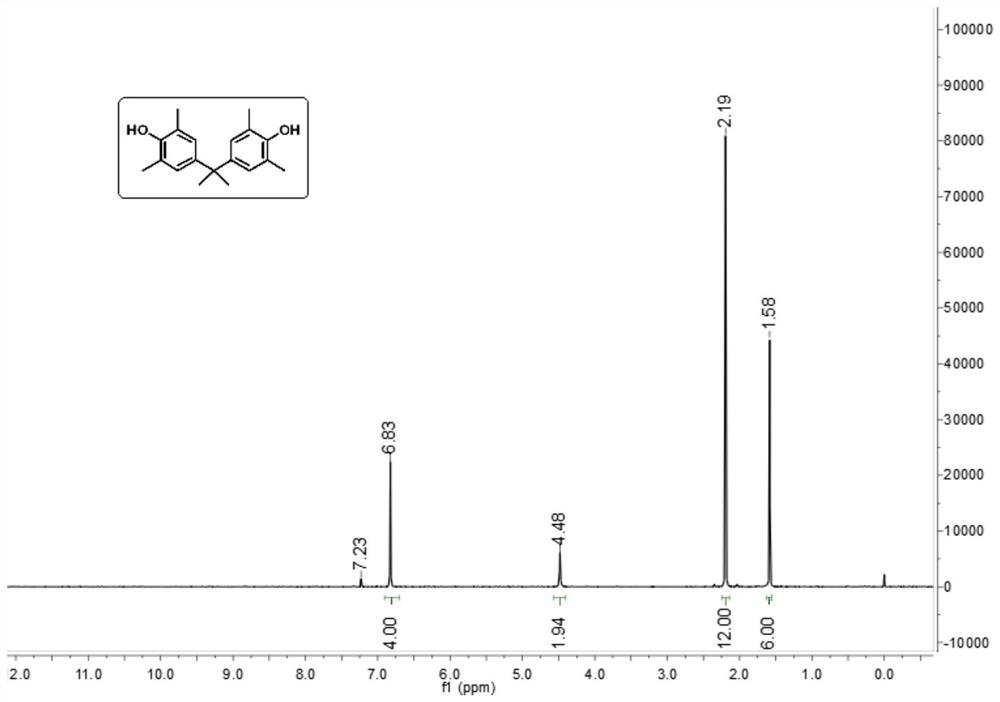

[0033]The method for synthesizing 2,2-bis(4-hydroxyl-3,5-dimethylphenyl)propane using a microchannel reactor, the steps are:

[0034] a. Equipped with reactor and raw materials:

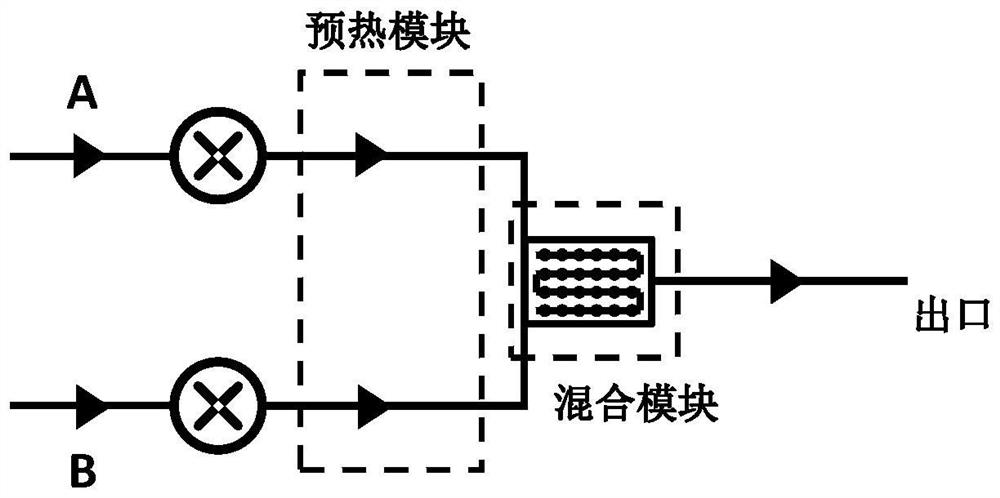

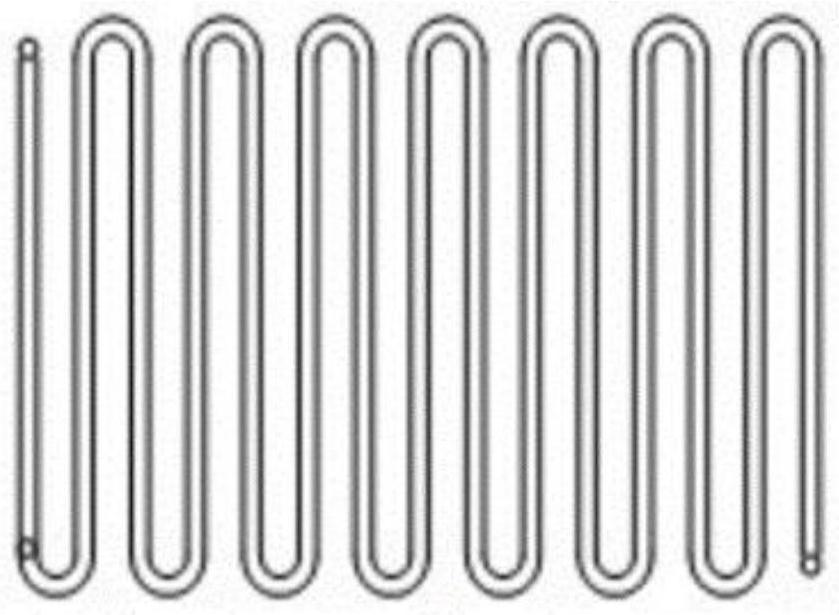

[0035] Equipped with Corning high-throughput continuous flow microchannel reactor (direct-flow microchannel preheating module + T-type microchannel enhanced mass transfer mixing module) as the reactor, the number of mixed reaction modules is determined according to the flow rate and reaction residence time, and the heat exchange medium For heat transfer oil;

[0036] The Corning high-flux continuous flow microchannel reactor contains (i.e. includes) a direct-flow type preheating module (i.e. a direct-flow microchannel preheating module), an enhanced mass transfer type mixing module (i.e. a T-type microchannel enhanced mass transfer type Mixing module), A entrance, B entrance, exit;

[0037] Using molten 2,6-dimethylphenol and acetone as raw materials, using hydrochloric acid with a mass fraction of...

Embodiment 2

[0041] The method for synthesizing 2,2-bis(4-hydroxyl-3,5-dimethylphenyl)propane using a microchannel reactor, the steps are:

[0042] a. Equipped with reactor and raw materials:

[0043] Equipped with Corning high-throughput continuous flow microchannel reactor (direct-flow microchannel preheating module + spherical microchannel enhanced mass transfer mixing module) as the reactor, the number of mixed reaction modules is determined according to the flow rate and reaction residence time, and the heat exchange medium For heat transfer oil;

[0044] The Corning high-throughput continuous flow microchannel reactor contains (that is, includes) a direct-flow type preheating module (that is, a direct-flow microchannel preheating module), an enhanced mass transfer type mixing module (that is, a spherical microchannel enhanced mass transfer type Mixing module), A entrance, B entrance, exit;

[0045] Using molten 2,6-dimethylphenol and aldehyde or ketone solution as raw materials, us...

Embodiment 3

[0049] The method for synthesizing 2,2-bis(4-hydroxyl-3,5-dimethylphenyl)propane using a microchannel reactor, the steps are:

[0050] a. Equipped with reactor and raw materials:

[0051] Equipped with Corning high-throughput continuous flow microchannel reactor (direct-flow microchannel preheating module + heart-shaped microchannel enhanced mass transfer mixing module) as the reactor, the number of mixed reaction modules is determined according to the flow rate and reaction residence time, and the heat exchange medium For heat transfer oil;

[0052] The Corning high-throughput continuous flow microchannel reactor contains (that is, includes) a direct-flow type preheating module (that is, a direct-flow microchannel preheating module), an enhanced mass transfer type mixing module (that is, a heart-shaped microchannel enhanced mass transfer type) Mixing module), A entrance, B entrance, exit;

[0053] Using molten 2,6-dimethylphenol and acetone as raw materials, taking sulfuric...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap