Denitration agent, preparation method thereof and flue gas purification method

A denitrification agent and flue gas technology, applied in the field of flue gas denitrification, can solve the problems of inability to meet treatment requirements, unfavorable reactions proceed stably, low material reactivity, etc., to solve furnace wall corrosion, alleviate ammonia escape, and reaction selectivity. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

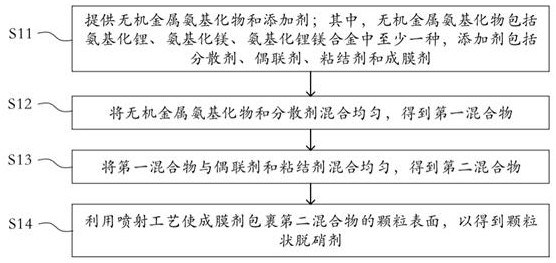

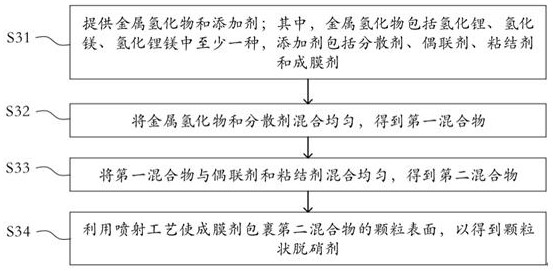

[0042] Based on the same inventive concept, the present application also provides a method for preparing a denitration agent, please refer to figure 1 , figure 1 It is a schematic flow chart of an embodiment of the preparation method of the denitrification agent of the present application, and the preparation method includes the following steps.

[0043] Step S11, providing an inorganic metal amide and an additive; wherein, the inorganic metal amide includes at least one of lithium amide, magnesium amide, and lithium-magnesium amide alloy, and the additive includes a dispersant, a coupling agent, a binder, and a forming agent. film.

[0044] Inorganic metal amide A (NH 2 ) x For the specific properties and reaction mechanism of , please refer to the above-mentioned embodiments, which will not be repeated here.

[0045] In step S12, the inorganic metal amide and the dispersant are uniformly mixed to obtain a first mixture. Dispersants are used to promote the dispersion and...

Embodiment 1

[0144]Weigh 68 parts of magnesium amide and 2.6 parts of white carbon black and place them in a horizontal mixer to mix, the stirring speed is 40 rev / min, and the stirring time is 15 minutes to obtain the first mixture Ta1; further, introduce 1.6 parts of silane in Ta1 The coupling agent and 0.8 parts of E51 epoxy resin were mixed uniformly in a horizontal mixer, the stirring speed was 80 rpm, and the stirring time was 5 minutes to obtain a granular second mixture Ta2 with a diameter of 2mm-3mm; In the rotating machine, the rotating stirring rate was 60 rpm, and the stirring time was 8 minutes. While stirring, 0.4 parts of polyurethane was sprayed and wrapped on the surface of Ta2 by the spraying process. The spraying process temperature was 160 °C, and the spraying process pressure was 6 bar. After cooling and drying, a granular denitration agent Ta with a diameter of 2mm-3mm is obtained.

[0145] The denitration agent Ta prepared in Example 1 is injected into the furnace, th...

Embodiment 2

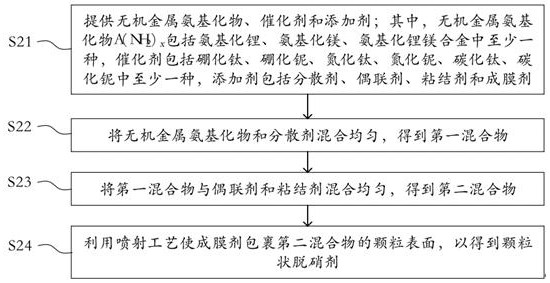

[0150] Weigh 68 parts of magnesium amide, 1.6 parts of titanium nitride and 2.6 parts of white carbon black and place them in a horizontal mixer to mix, the stirring speed is 40 rev / min, and the stirring time is 15 minutes to obtain the first mixture Tb1; further, in Introduce 1.6 parts of silane coupling agent and 0.8 parts of E51 epoxy resin into Tb1, mix them uniformly in a horizontal mixer, the stirring speed is 80 rpm, and the stirring time is 5 minutes to obtain a granular second mixture with a diameter of 2mm-3mm Tb2; put Tb2 in a rotating machine, the rotating stirring rate is 60 r / min, and the stirring time is 8 minutes. While stirring, 0.4 parts of polyurethane is sprayed and wrapped on the surface of Tb2 by the spraying process. The spraying process temperature is 160 ° C. The spraying process The pressure is 6 bar, and after cooling and drying, a granular denitration agent Tb with a diameter of 2mm-3mm is obtained.

[0151] The denitration agent Tb prepared in Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com