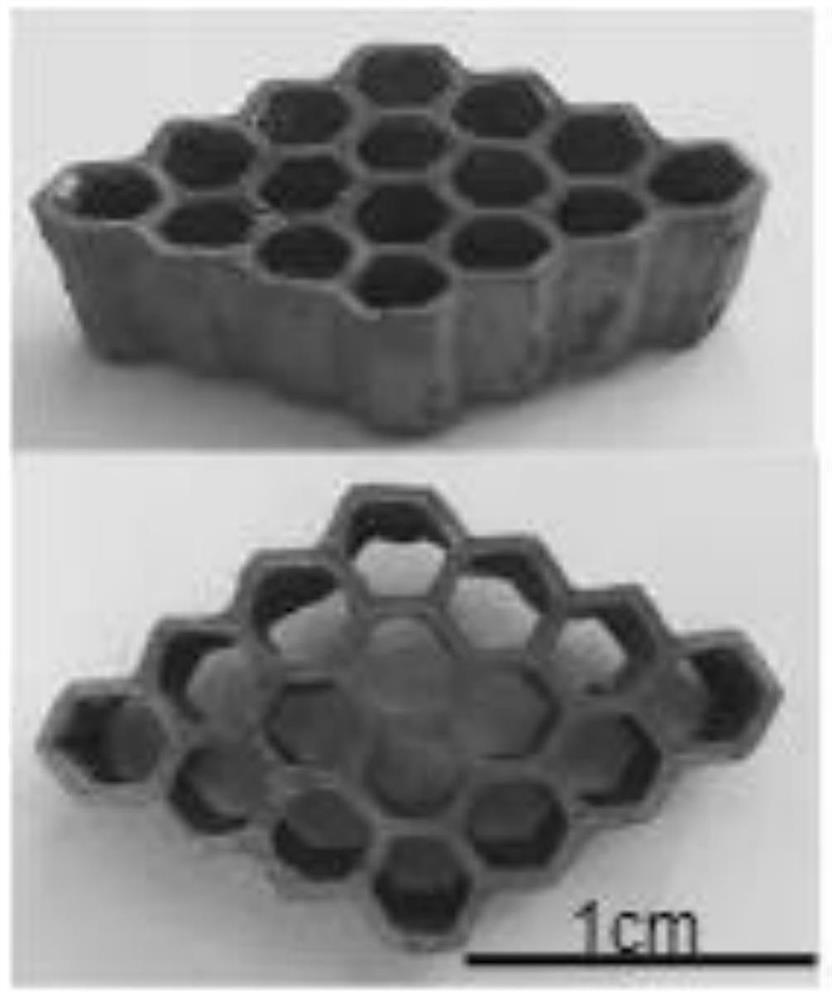

Method for preparing hard alloy with three-dimensional structure through photocuring 3D printing

A 3D printing and three-dimensional structure technology, applied in the field of additive manufacturing, can solve the problems of discontinuous large holes and small holes, high sphericity and high loose packing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Using sodium tungstate as tungsten salt, three-dimensional structure cemented carbide was prepared by light-curing 3D printing:

[0047] At room temperature, deionized water (5 g), sodium tungstate (5 g), cobalt acetate (1 g), acrylic acid (5 g) and N, N'-methylenebisacrylamide (0.2 g) were mixed with photoinitiator TPO (0.1g) were mixed, and magnetically stirred to prepare photocurable 3D printing ink. The temperature for all operations was controlled at around 20°C.

[0048] Then carry out photo-curing 3D printing, the photo-curing 3D printing layer thickness is 0.01mm, and the exposure time of each layer is 1s.

[0049] The printed green body was taken out from the trough, and then placed at a humidity of 80% and a temperature of 60°C for 96 hours to make the green body completely dry.

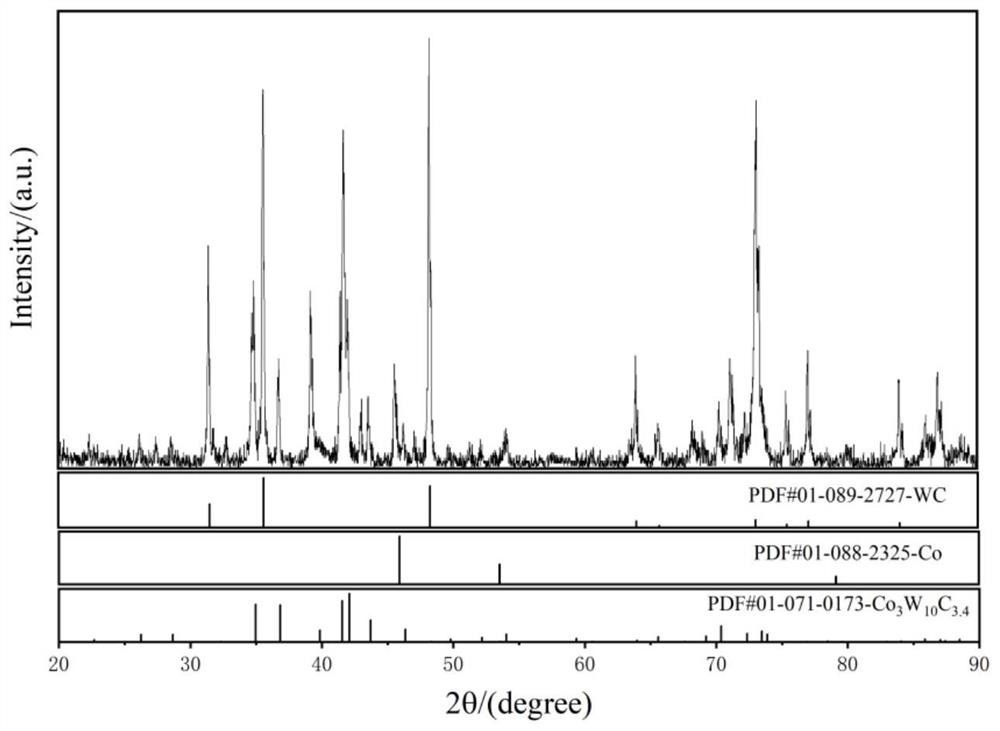

[0050] Finally, the green body was placed in hydrogen, and the temperature was raised to 500°C at a rate of 0.5°C / min for 2 hours, and the temperature was raised to 900°C at a rate...

Embodiment 2

[0052] Using ammonium paratungstate as tungsten salt, three-dimensional structure cemented carbide was prepared by light-curing 3D printing

[0053] At room temperature, deionized water (4 g), ammonium paratungstate (6 g), cobalt nitrate (1 g), acrylic acid (6 g) and ethyl methacrylate (0.3 g) were magnetically stirred with photoinitiator 651 (0.1 g) to prepare Light curing 3D printing ink. The temperature for all operations was controlled at around 20°C.

[0054] Then carry out photo-curing 3D printing, the photo-curing 3D printing layer thickness is 0.01mm, and the exposure time of each layer is 1s.

[0055] The molded green body is taken out from the trough, and then placed at a humidity of 80% and a temperature of 70° C. for 48 hours to make the green body completely dry.

[0056] Finally, the green body was placed in hydrogen, and the temperature was raised to 400°C at a rate of 0.5°C / min for 2 hours, and the temperature was raised to 1000°C at a rate of 5°C / min under v...

Embodiment 3

[0058] Using ammonium metatungstate as tungsten salt, three-dimensional structure cemented carbide was prepared by light-curing 3D printing

[0059] At room temperature, deionized water (3g), ammonium metatungstate (10g), cobalt acetate (1.5g), acrylic acid (6g) and polyethylene glycol dimethacrylate (1g) were mixed with photoinitiator TPO- L (0.1g) was subjected to magnetic stirring to prepare photocurable 3D printing ink. The temperature for all operations was controlled at around 20°C.

[0060] Then carry out photo-curing 3D printing, the photo-curing 3D printing layer thickness is 0.01mm, and the exposure time of each layer is 1s.

[0061] Take the molded green body out of the trough, put it in a freeze dryer, let it cool down to -70°C, then gradually raise the temperature to 20°C, and make the green body completely dry with a vacuum degree of 0.01MPa.

[0062] Finally, the green body was placed in hydrogen, and the temperature was raised to 500 ° C at a rate of 0.5 ° C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com