Catalytic conversion method for inferior oil product

A technology for catalytic conversion and oil products, applied in chemical instruments and methods, molecular sieve catalysts, physical/chemical process catalysts, etc., can solve the problems of shortage of resources, limited output of paraffin-based crude oil, etc., and achieve high yields of low-carbon olefins and aromatics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

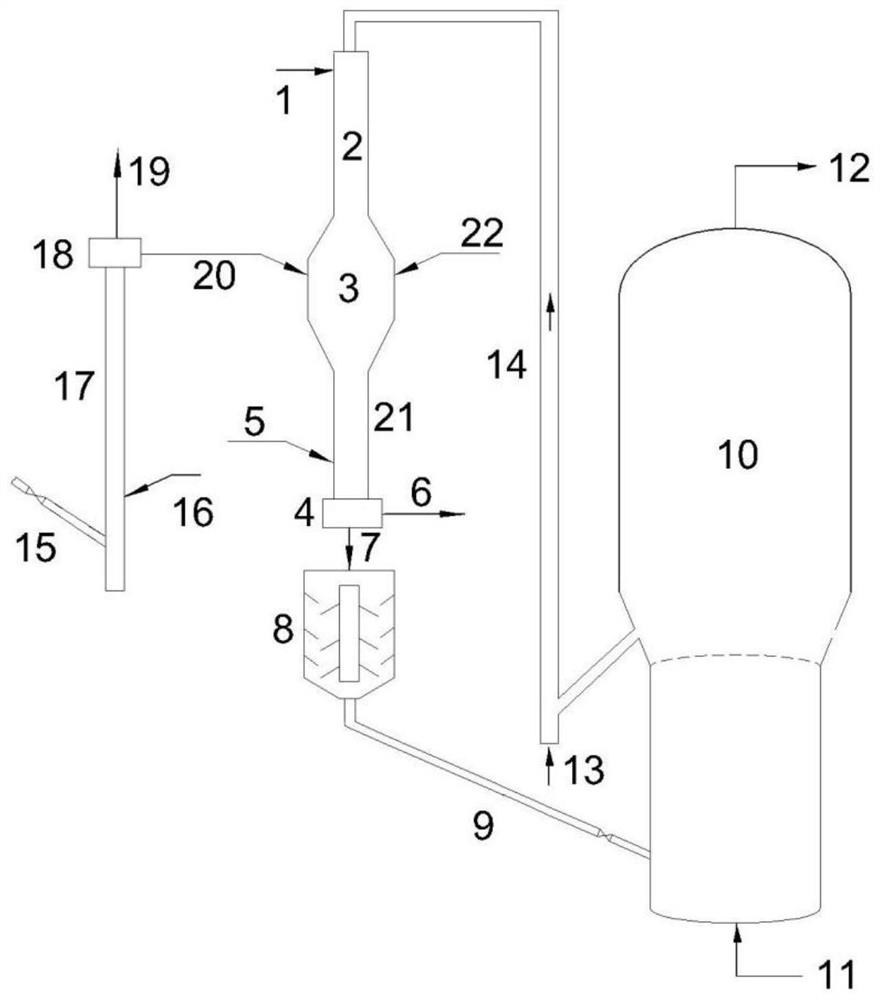

Method used

Image

Examples

Embodiment 1

[0037] The preparation process of the catalyst used is as follows. Mix kaolin, halloysite and water for beating, add amorphous silica-alumina oxide, alumina, silica gel and stir evenly, then add aluminum sol for beating evenly, finally add MFI modified molecular sieve, FAU modified molecular sieve, BEA molecular sieve and stir evenly, Adjust the pH of the slurry to 3.5 to 4.0, then add a mixed solution of ferric nitrate, magnesium nitrate, cerium nitrate, and manganese nitrate, and stir evenly. Calculated on a dry basis of oxides, kaolin, halloysite, amorphous silicon aluminum oxide, and Silicon, aluminum sol, MFI modified molecular sieve, FAU modified molecular sieve, BEA molecular sieve and the ratio of iron oxide, magnesium oxide, cerium oxide, manganese oxide are 30.0%, 6.4%, 8.5%, 3.5%, 5.0%, 24.0%, 6.5%, 5.4%, and 4.0%, 1.6%, 3.0%, 2.1%, the solid content is controlled at 27%, and the mixed slurry is spray-molded.

[0038] The preparation method of MFI modified molecula...

Embodiment 2

[0052] This example uses raw material oil with embodiment 1, uses catalyst to be conventional catalytic cracking catalyst. The catalyst is composed of kaolin, aluminum oxide, aluminum sol binder and molecular sieve, and the proportions of Y molecular sieve and ZSM-5 contained in the catalyst are 16.5 and 18.3% respectively. Operation scheme is the same as embodiment 1. The implementation effect is listed in Table 2.

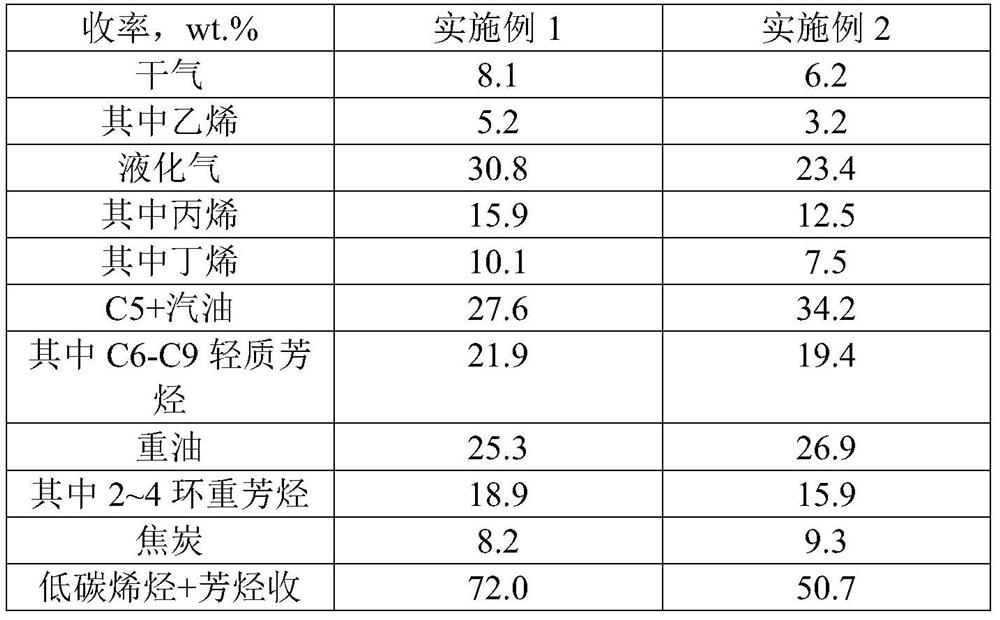

[0053] As can be seen from Table 2, using the method provided by the invention, when using the inferior intermediate heavy oil with a hydrogen content of 12.29%, an asphaltene content of 3.0%, and nickel and vanadium content of 12.5 μg / g and 5.1 μg / g as raw material, the implementation The total yield of low carbon olefins and aromatics in Example 2 has also reached 50.7%, and the yield of low carbon olefins in Example 1 has reached 31.2%, the total yield of low carbon olefins and aromatics has reached 72.0%, and the coke yield has only 8.2% %, the two examples...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com