Crucible melt remote monitoring, temperature control and feeding system for nano nickel powder production

A remote control system, nano-nickel powder technology, applied in the remote monitoring of crucible melt, feeding system, temperature control field, can solve the problems of poor quality of nano-nickel powder, low production efficiency, fragile sensors, etc., to reduce environmental pollution, The effect of improving production efficiency and improving smelting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

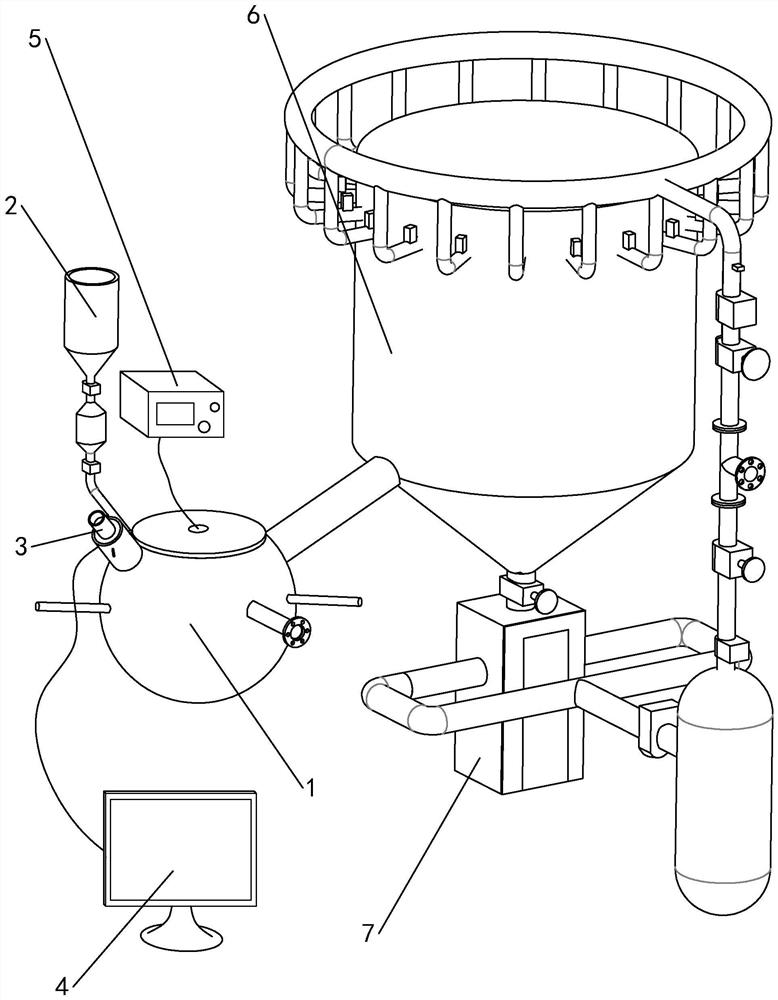

[0039] exist figure 1 Among them, the crucible melt remote monitoring, temperature control, and feeding system produced by nano-nickel powder includes a smelting evaporation device 1, a combined sensor device 3, an automatic isolation feeding device 2, an arc plasma controller 5, and a remote computer. Control system 4, condensation system 6, nanometer nickel powder collection device 7.

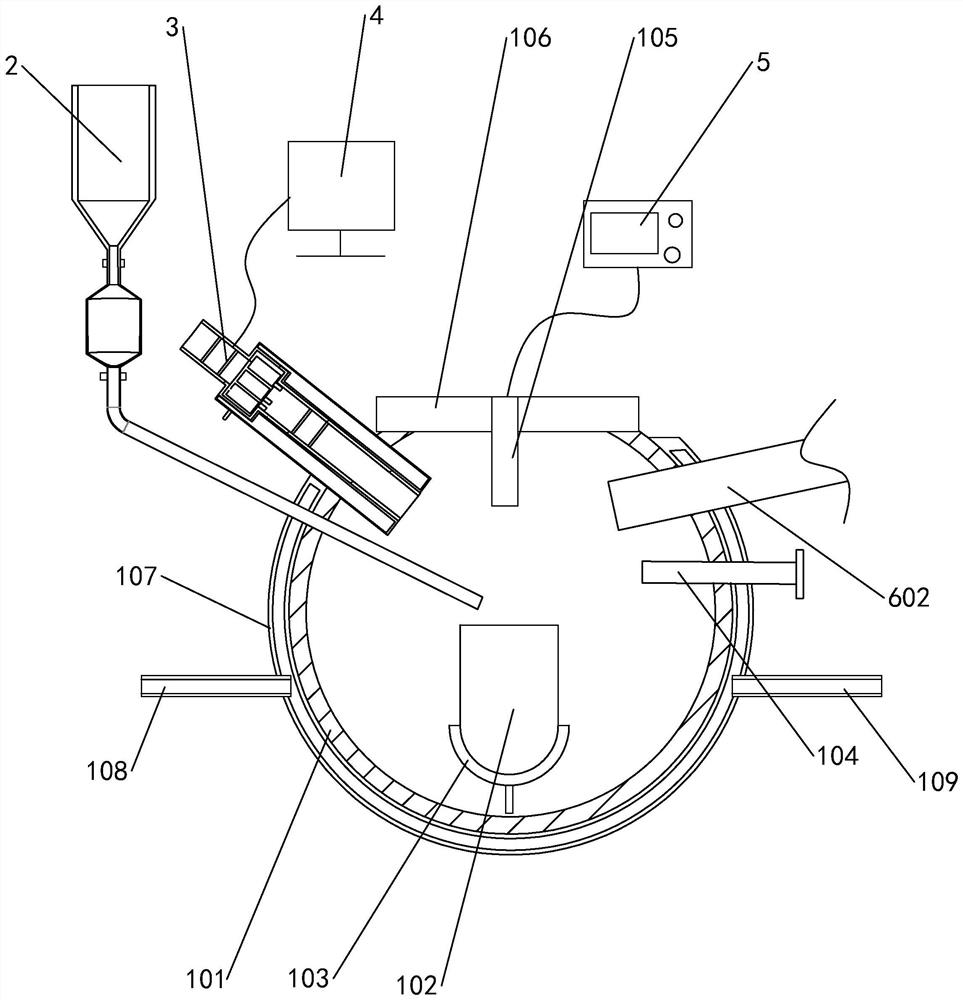

[0040] exist figure 2 Among them, the smelting and evaporating device 1 includes a crucible 102, an inner shell 101, a cathode 105, an anode 103, a hydrogen-argon gas mixture input pipe 104, a cover plate 106, an outer shell 107, a cooling water input pipe B108, and a cooling water output pipe B109; the inner casing 101 and the outer casing 107 are spherical, and a detachable cover plate 106 with an opening is arranged on the top, and a cathode 105 is installed on the cover plate 106, and the cathode 105 is connected to the arc plasma controller 5 An anode 103 is installed at the bottom of...

Embodiment 2

[0052] exist figure 1 Among them, the crucible melt remote monitoring, temperature control, and feeding system produced by nano-nickel powder includes a smelting evaporation device 1, a combined sensor device 3, an automatic isolation feeding device 2, an arc plasma controller 5, and a remote computer. Control system 4, condensation system 6, nanometer nickel powder collection device 7.

[0053] exist figure 2 Among them, the smelting and evaporating device 1 includes a crucible 102, an inner shell 101, a cathode 105, an anode 103, a hydrogen-argon gas mixture input pipe 104, a cover plate 106, an outer shell 107, a cooling water input pipe B108, and a cooling water output pipe B109; the inner casing 101 and the outer casing 107 are spherical, and a detachable cover plate 106 with an opening is arranged on the top, and a cathode 105 is installed on the cover plate 106, and the cathode 105 is connected to the arc plasma controller 5 An anode 103 is installed at the bottom of...

Embodiment 3

[0065] exist figure 1 Among them, the crucible melt remote monitoring, temperature control, and feeding system produced by nano-nickel powder includes a smelting evaporation device 1, a combined sensor device 3, an automatic isolation feeding device 2, an arc plasma controller 5, and a remote computer. Control system 4, condensation system 6, nanometer nickel powder collection device 7.

[0066] exist figure 2 Among them, the smelting and evaporating device 1 includes a crucible 102, an inner shell 101, a cathode 105, an anode 103, a hydrogen-argon gas mixture input pipe 104, a cover plate 106, an outer shell 107, a cooling water input pipe B108, and a cooling water output pipe B109; the inner casing 101 and the outer casing 107 are spherical, and a detachable cover plate 106 with an opening is arranged on the top, and a cathode 105 is installed on the cover plate 106, and the cathode 105 is connected to the arc plasma controller 5 An anode 103 is installed at the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com