Electrooptical sensor static bias point process correction method and electro-optical sensor

An electro-optic sensor and static bias technology, applied in the field of sensors, can solve the problems of reducing the anti-electromagnetic interference performance of electro-optic sensors, failing to realize the π/2 static bias point, increasing the interference of electro-optic sensors, etc., and achieving good size reduction characteristics and structure Simple, effective method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

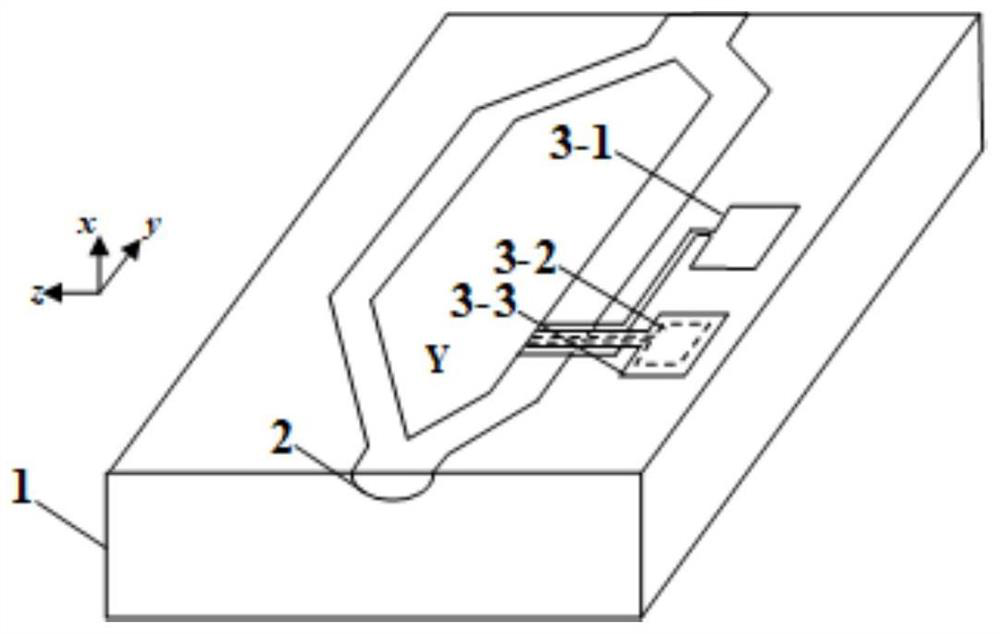

[0080] like figure 1 As shown, the substrate 1 of the electro-optic sensor is a bulk lithium niobate substrate, so the electro-optic sensor does not include the bonding buffer layer 4 and the support material 5 . Lithium niobate optical waveguide 2 adopts MZ interference optical path made by titanium diffusion or proton exchange process. The lower electrode 3-1 is made of indium tin oxide (ITO); the transition metal oxide resistive material layer 3-2 is made of tungsten trioxide (WO 3 ); the upper electrode 3-3 is made of indium tin oxide. Wherein, both Y branches in the MZ interference optical path can be replaced by a multimode interferometer (MMI).

[0081] In this technical solution, the tangential direction of the bulk lithium niobate substrate is x-cut, and the propagation direction of light is along the y-direction. The crystal coordinate system is as figure 1 The middle axis is shown.

Embodiment 2

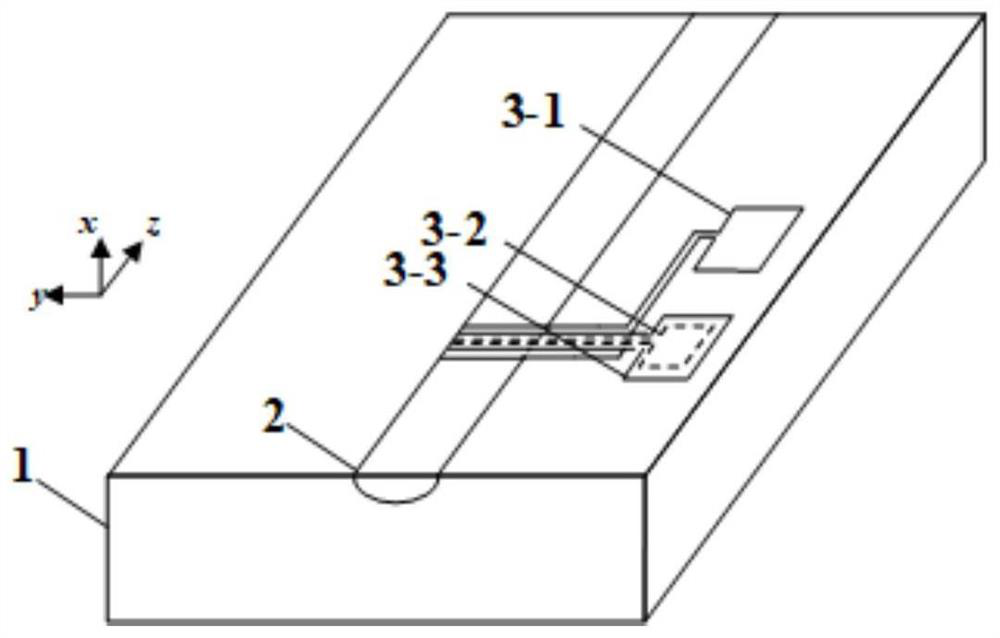

[0083] like figure 2 As shown, the substrate 1 of the electro-optic sensor is a bulk lithium niobate substrate, so the electro-optic sensor does not include the bonding buffer layer 4 and the support material 5 . The lithium niobate optical waveguide 2 is a common path interference optical path made by titanium diffusion or proton exchange technology. The lower electrode 3-1 is made of fluorine-doped tin oxide (FTO); the transition metal oxide resistive material layer 3-2 is made of titanium dioxide (TiO 2 ); the upper electrode 3-3 uses platinum (Pt).

[0084] In this technical solution, the tangent direction of the bulk lithium niobate substrate is x-cut, and the propagation direction of light is along the z-direction. The crystal coordinate system is as figure 2 The middle axis is shown.

Embodiment 3

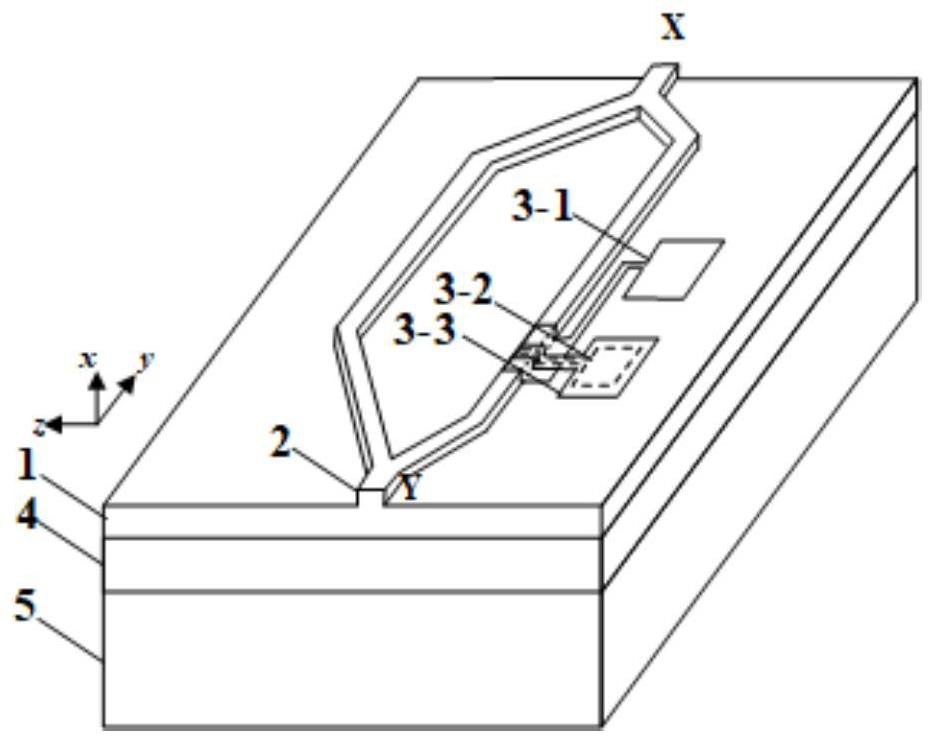

[0086] like image 3 As shown, the substrate 1 of the electro-optical sensor uses thin-film lithium niobate, which needs to be placed on the surface of the support material 5 through the bonding buffer layer 4 . Lithium niobate optical waveguide 2 is an MZ interference optical path made by etching or laser processing technology. The lower electrode 3-1 is made of indium tin oxide (ITO); the transition metal oxide resistive material layer 3-2 is made of niobium pentoxide (Nb 2 o 5 ); the upper electrode 3-3 is made of fluorine-doped tin oxide. The bonding buffer layer 4 is made of silicon dioxide. The support material 5 is block lithium niobate.

[0087] In this technical solution, the tangent direction of the lithium niobate film is x-cut, and the propagation direction of light is along the y direction. The crystal coordinate system is as image 3 The middle axis is shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com