Preparation process of bacteriostatic bacillus subtilis microecological preparation

A technology of Bacillus subtilis and microecological preparations, which is applied in the field of preparation technology of bacteriostatic Bacillus subtilis and microecological preparations, can solve problems such as the gap in effect and achieve the effect of strong high temperature resistance and strong antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

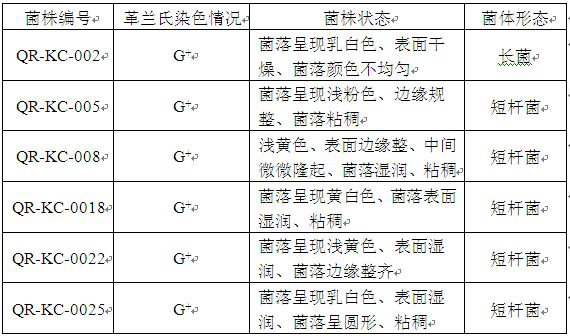

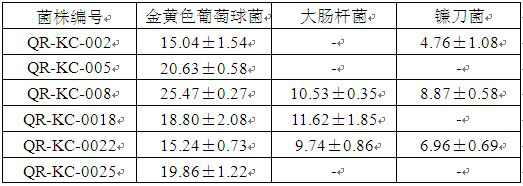

[0033] The separation and purification of embodiment 1 Bacillus subtilis QR-KC-008:

[0034] (1) Sample processing:

[0035] The sandy soil near the company was selected as the sample, and the soil sample was boiled in sterile water at 90°C for 20 minutes.

[0036] (2) Then use an inoculation loop to dip the treated sample solution into the solidified plate culture medium on the slope of the mother species, mark the line, and incubate in a 40°C incubator at a constant temperature for 24 hours, and pick colonies with good growth and similar colonies And the colony with the largest number is isolated and purified until the single bacteria with the same colony shape, and the isolated single bacteria are subjected to protease detection test, bacteriostatic test, and Gram staining microscope inspection.

[0037] The plate medium is: 2% glucose, 0.5% peptone, 0.1% yeast extract, 0.02% magnesium sulfate, 0.15% potassium dihydrogen phosphate, 1% sodium chloride, 2% agar, pH 7.0.

[...

Embodiment 2

[0054] Example 2 Bacillus subtilis QR-KC-008 fermentation production process.

[0055] The preferred bacterial strain QR-KC-008 obtained by screening in Example 1 was expanded and cultivated to prepare bacterial powder. The specific production process is as follows:

[0056] The preparation process of Bacillus subtilis bacterial agent of the present invention comprises the following concrete steps:

[0057] (1) The strain is Bacillus subtilis strain numbered QR-KC-008;

[0058] (2) Cultivation of slant mother species: Inoculate Bacillus subtilis strains preserved in glycerol freeze-dried tubes on solid slant medium and culture at 40°C for 2 days;

[0059] (3) Erlenmeyer flask mother seed culture: Inoculate the prepared slant mother seed under sterile conditions, pick two rings with an inoculation loop and put them in 150mL triangular flask mother seed medium, and cultivate at 40°C, 150r / min for 1.5 d, making the first-grade triangular flask seed solution;

[0060] (4) Expan...

Embodiment 3

[0067] Example 3 Preparation process of Bacillus subtilis QR-KC-008 probiotics.

[0068] Use the QR-KC-008 fermented in Example 2 to ferment, use the GQ-105 centrifuge to set the speed at 16000r / min, feed the flow rate at 2.68L / min, and centrifuge. After the centrifugation, collect the sludge and place it in a 4°C freezer Save for later use. Centrifuge the bacteria slurry to dissolve.

[0069] The preparation process of Bacillus subtilis QR-KC-008 probiotics mainly includes the following steps:

[0070] (1) Preparation of Bacillus subtilis QR-KC-008 suspension, using sterile saline at 250r / min to stir for 15min to prepare the centrifuged sludge into 30% (w / v) bacterial suspension;

[0071] (2) Preparation of core material mixture mixture: Sodium alginate 2% (w / v), glycerin 4.5% (w / v), carbogel 0.5% (w / v), Tween 80 0.2% (w / v) Add 30% (w / v) of Bacillus subtilis QR-KC-008 to a certain amount of distilled water and mix well;

[0072] (3) Inject the core material mixture prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com