Large-specific-surface-area barium carbonate as well as preparation method and application thereof

A technology with large specific surface area and barium carbonate, applied in the field of materials, can solve the problems of slow reaction process, high cost of raw materials, equipment requirements and high production cost, and achieves the effect of simple operation process, mild reaction conditions and inhibition of agglomeration phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

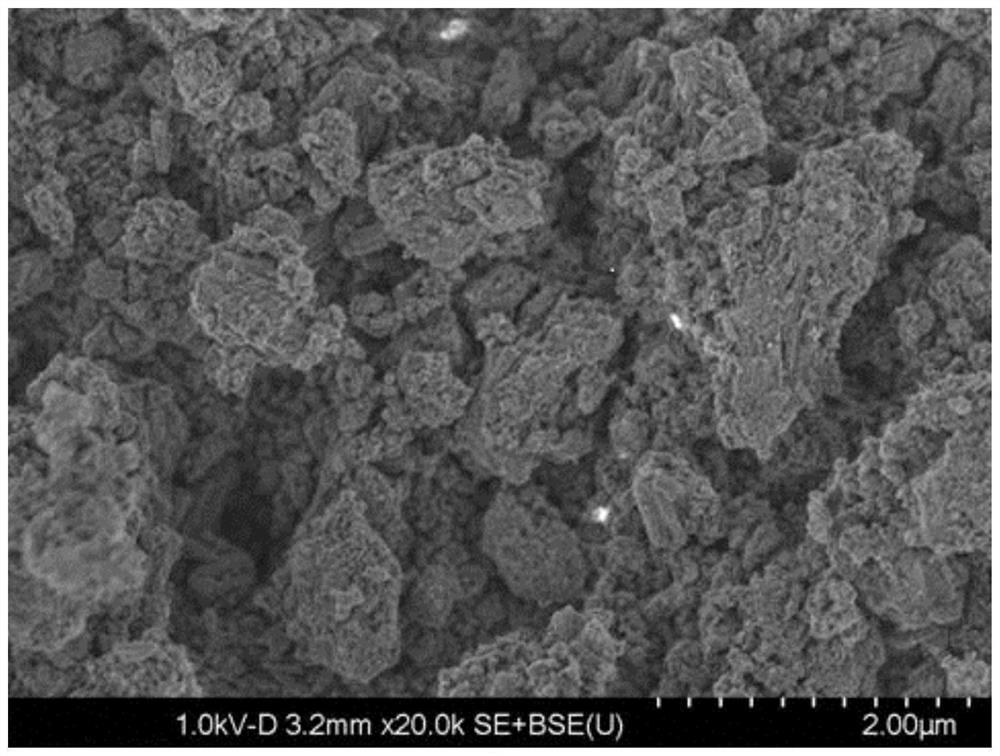

Image

Examples

preparation example Construction

[0044] First aspect, the present invention provides a kind of preparation method of barium carbonate of large specific surface area, comprises the following steps:

[0045] Add barium salt solution and carbonate solution to the dispersant solution for reaction, and prepare barium carbonate with large specific surface area after heat preservation treatment;

[0046] The barium salt solution is added to the dispersant solution one step earlier than the carbonate solution;

[0047] The barium salt solution is also dissolved with a growth regulator;

[0048] The growth regulator includes at least one of ammonium polyacrylate, polyvinyl alcohol, polyethylene glycol, carboxymethyl cellulose, polyacrylamide or polycarboxylate ammonium salt obtained through alkalization;

[0049] The barium salt includes at least one of barium chloride, barium sulfate and barium hydroxide;

[0050] The carbonates include ammonium carbonate and / or sodium carbonate.

[0051]In some embodiments of the...

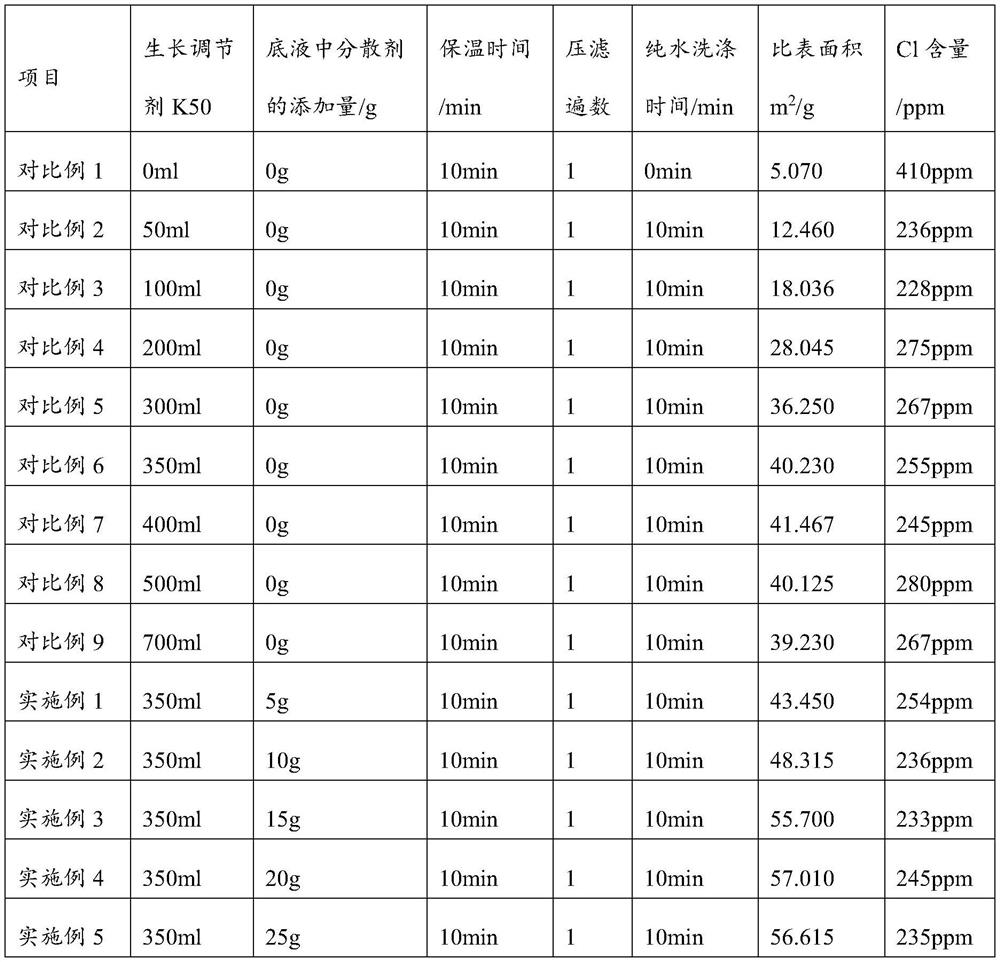

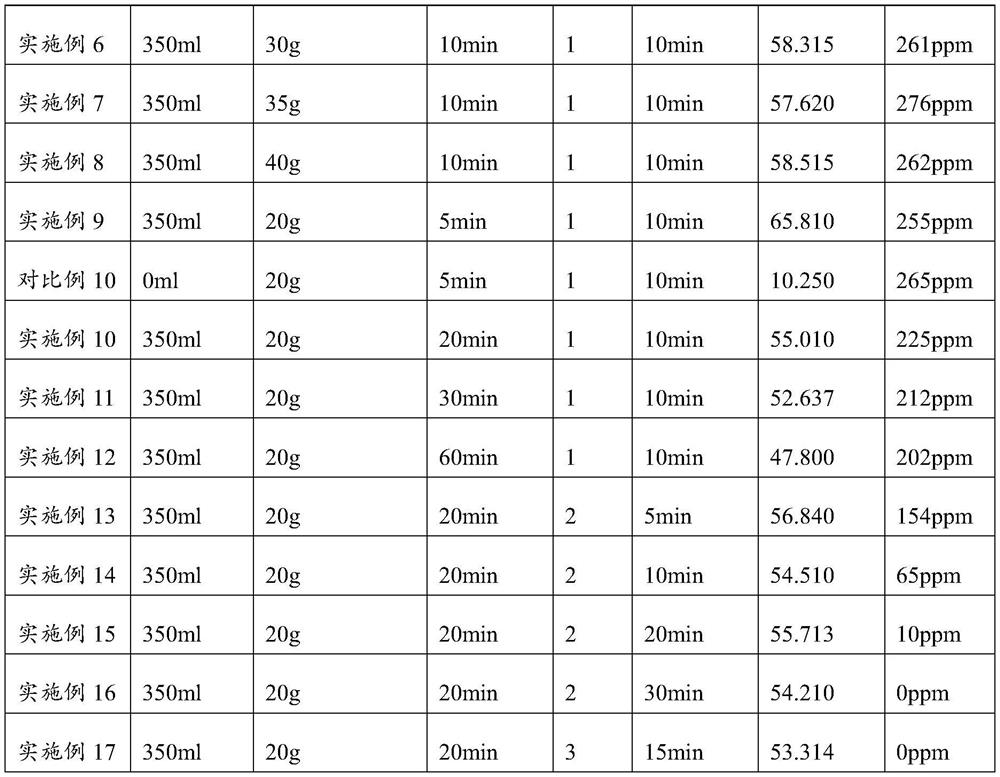

Embodiment 1-17 and comparative example 1-10

[0082] A kind of preparation method of barium carbonate of large specific surface area, comprises the steps:

[0083] (1) Preparation of the growth regulator used, code number K50, take 50g of ammonium polyacrylate, add 450ml of pure water and mix evenly, add 25ml of concentrated ammonia water with a mass concentration of 25% to carry out ammoniation treatment for 10min, and seal it for later use.

[0084] (2) Add the growth regulator K50 prepared in step (1) into 15 L of barium chloride solution with a molar concentration of 1.0 mol / L, set the stirring speed to 150 r / min, stir for 20 min, and set aside.

[0085] (3) Preparation of the base liquid, take 20 g of polyacrylamide as a dispersant, add 2 L of pure water, and stir at a speed of 100 r / min.

[0086] (4) Use a peristaltic pump to transport raw materials. During the process, add barium chloride dropwise while stirring the bottom liquid. After adding dropwise for 3 minutes, then add ammonium carbonate dropwise to control ...

Embodiment 18

[0093] A kind of preparation method of barium carbonate of large specific surface area, the difference with embodiment 9 is that growth regulator is different from the dispersant that adopts, and the preparation of growth regulator is as follows:

[0094] Take 50g of polyvinyl alcohol, add 450ml of pure water and mix evenly, add 25ml of concentrated ammonia water with a mass concentration of 25% to carry out ammoniation treatment for 10min, and seal it for later use.

[0095] The dispersant is sodium hexametaphosphate.

[0096] The specific surface area of the prepared barium carbonate is 64.020m 2 / g, Cl content is 270ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com