Method for separating beet polysaccharide and betaine by coupling compound enzyme with continuous nanofiltration membrane

A compound enzyme and betaine technology, applied in chemical instruments and methods, preparation of organic compounds, climate sustainability, etc., can solve problems such as affecting the crystallization rate and quality of sugar products, high process energy consumption, and low sugar production efficiency. , to reduce the viscosity of the feed liquid, make full use of resources and increase the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

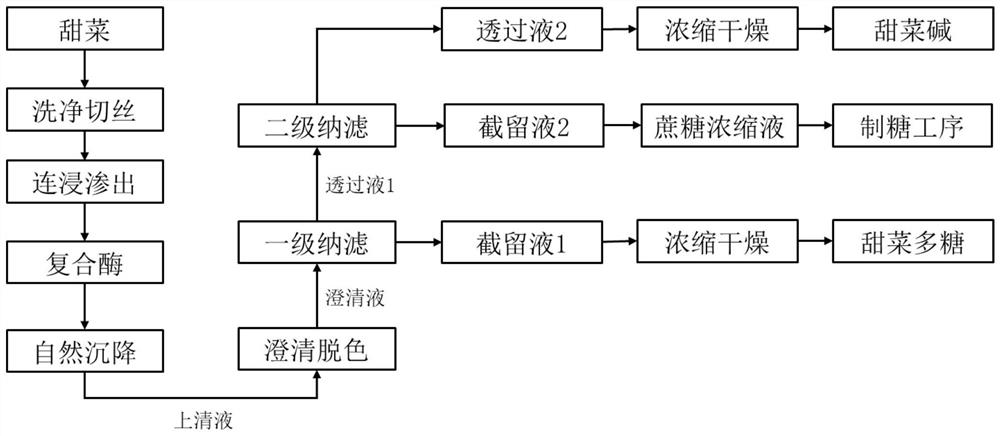

[0034] A method for separating beet polysaccharide and betaine by a composite enzyme coupled continuous nanofiltration membrane, the specific steps are as follows (see attached figure 1 ):

[0035] (1) Pretreatment: After the sugar beet is washed and shredded, water is used as the extract, which is continuously exuded in the exudator, and impurities are removed in the hydrocyclone to obtain the beet extract.

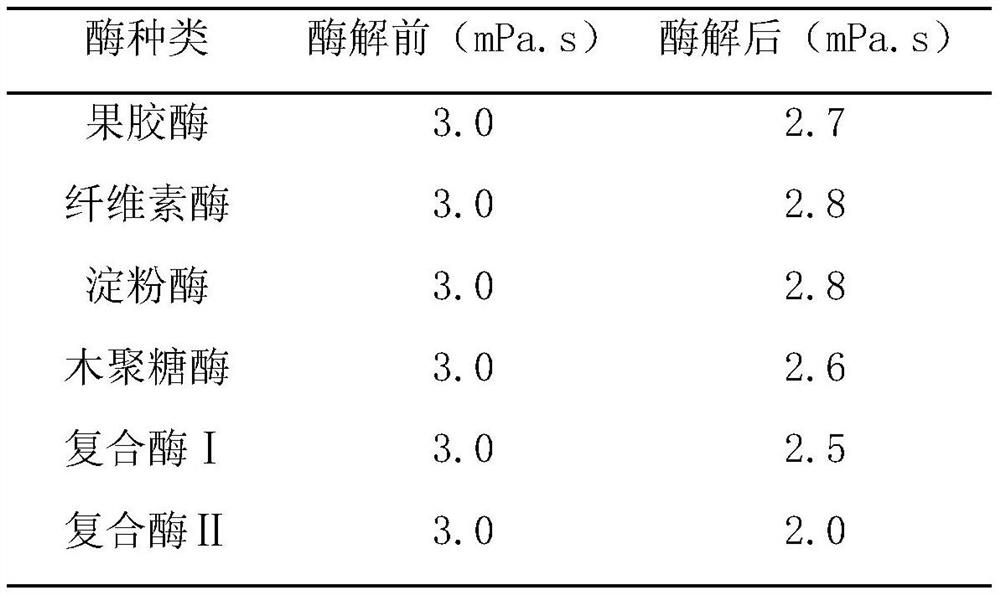

[0036] (2) Compound enzymatic hydrolysis: add 3‰(w / v) compound enzyme (pectinase:amylase:xylanase=7:2:1) to the sugar beet extract, mix well, adjust with citric acid The pH of the feed solution was 5, and the temperature was heated to 45° C. for enzymatic hydrolysis for 2 h to obtain an enzymatic hydrolysis leaching solution. The processing capacity of the enzymatic hydrolysis tank in this example is 300m 3 / h.

[0037] (3) Clarification and decolorization: The enzymatic hydrolysis leaching solution settles naturally for 30 minutes, and the supernatant liquid is clari...

Embodiment 2

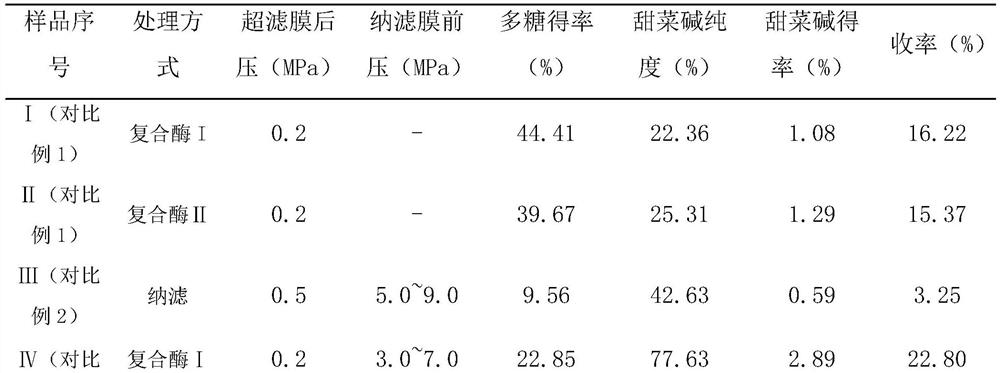

[0069] Detect the polysaccharide and betaine content of the dry beet polysaccharide and betaine dry products or beet polysaccharide and betaine mixed crude products obtained in Example 1 and Comparative Examples 1-3, and the results are shown in Table 2.

[0070] The yield of crude polysaccharide was measured by the phenol-sulfuric acid method (g of crude polysaccharide / weight of raw material g × 100%), and the purity of betaine in the freeze-dried crude product was measured by HPLC (g of betaine mass / weight of crude product / g × 100%); betaine Yield (betaine mass g / raw material weight g×100%), yield (betaine betaine total weight g / raw material weight g×100%).

[0071] Table 2

[0072]

[0073]

[0074] It can be seen from the above results that after the treatment of compound enzymes I and II, the monosaccharides, disaccharides and pectin enzymolysis products (galacturonic acid) and the same polysaccharides in the exudate enter the ultrafiltration stage together, and are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com