Three-dimensional nano molybdenum-based lithium ion battery negative electrode material and preparation method thereof

A lithium-ion battery, three-dimensional nanotechnology, applied in battery electrodes, nanotechnology, nanotechnology and other directions, can solve the problems of low specific energy storage capacity, poor charge-discharge cycle stability, etc., and achieve small energy storage capacity attenuation, The effect of stable structure and good energy storage capacity performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

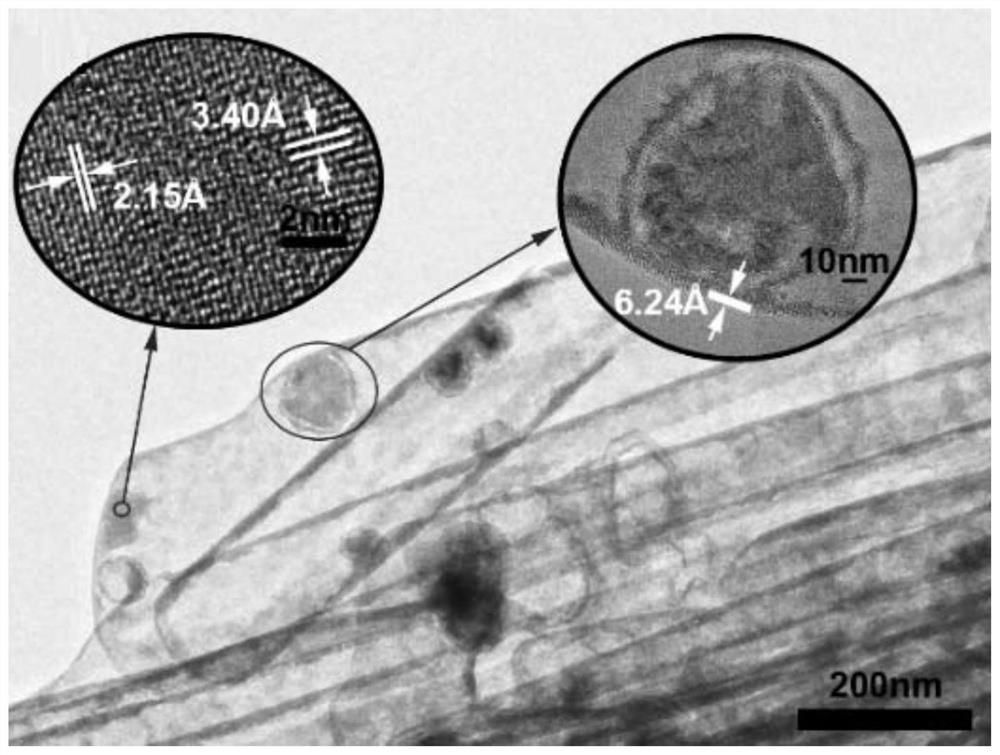

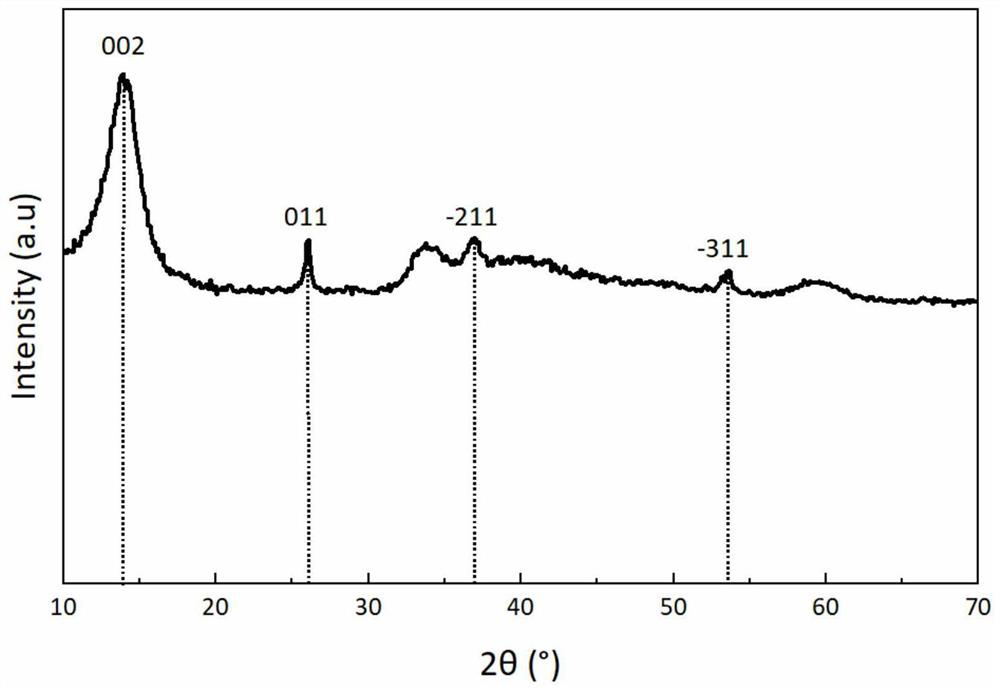

[0039] Place the molybdenum trioxide nanobelt sample in the middle of the quartz tube, and place a sufficient amount of sublimed sulfur sample near the inlet of the quartz tube, and discharge the internal air through the quartz tube with a flow rate of 500 sccm for 15 minutes, and then pass Inject hydrogen at a flow rate of 200 sccm, and heat to 300°C at a heating rate of 20°C / min. Then, the sublimated sulfur was slowly moved to the heating zone in the furnace at a temperature of 300°C and kept for 45 minutes. The sublimated sulfur reacts with hydrogen at 300°C to generate hydrogen sulfide gas, which realizes the surface sulfidation of the molybdenum trioxide nanobelt, so that the molybdenum disulfide nanomask grows in situ on the surface of the molybdenum trioxide nanobelt. Afterwards, the introduction of hydrogen gas was stopped, and the flow rate of 200 sccm was used to feed argon gas into the quartz tube, and the sample was cooled to room temperature to obtain a molybdenum...

Embodiment 2

[0042] The molybdenum trioxide nanoribbon sample is placed in the middle of the quartz tube, and the argon gas with a flow rate of 600 sccm is passed into the quartz tube for 15 minutes to exhaust the internal air, and then the hydrogen sulfide gas with a flow rate of 200 sccm is introduced, and the temperature is increased at 10 ° C / Heat up to 300°C at a heating rate of min and hold for 45 minutes. Afterwards, the introduction of hydrogen sulfide gas was stopped, and argon gas was introduced into the quartz tube at a flow rate of 300 sccm, and the sample was cooled to room temperature to obtain molybdenum disulfide nanomask nanobelts with molybdenum oxide inside.

[0043] Add 100 mg molybdenum disulfide nanomask nanobelts into 200 ml hydrochloric acid and stir magnetically for 24 hours. Then pour the solution into a centrifuge tube and centrifuge at a speed of 12000r / min for 10 minutes. After centrifugation, pour out the supernatant, add hydrochloric acid again to 200 ml, ...

Embodiment 3

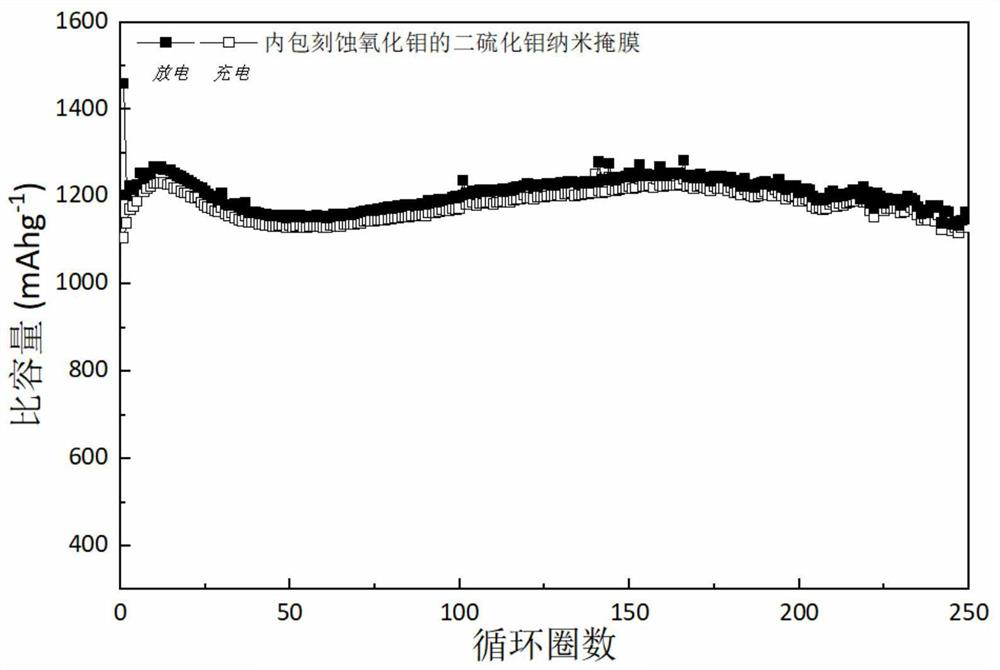

[0046] Carry out the making of lithium ion battery to the lithium ion battery material prepared by the present invention, the method is as follows:

[0047] The lithium-ion battery shell is a CR2025 button battery shell, the metal lithium sheet is used as the counter electrode, the metal copper foil is used as the collector electrode, and the microporous membrane of polypropylene material is used as the diaphragm (the model is Cellgard 2400), and the concentration is 1.0 mol / L LiPF 6 A solution of ethylene carbonate and dimethyl carbonate (volume ratio 1:1) was used as the electrolyte. Ultra-pure conductive carbon black powder is used as the conductive agent of the active material, and polyacrylic acid is used as the binder. The lithium ion battery material prepared in the present invention, the mass ratio of the conductive agent and the binder is 7:2:1, add an appropriate amount of ionic water to disperse, grind for about 20 minutes to make it fully and evenly mixed, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com