Method for industrially producing crotonic acid by adopting microchannel reactor

A micro-channel reactor, a technology for industrial production, applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, preparation of carboxylate salts, etc. Process development and other issues, to achieve the effect of reducing production steps, avoiding a large number of emissions, and shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

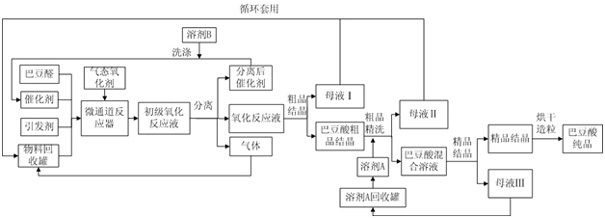

Image

Examples

Embodiment 1

[0049] A kind of method adopting microchannel reactor industrial production crotonic acid, carries out according to the following steps:

[0050] S1. Material oxidation process: Cobalt acetate, activated alumina, and iron phosphomolybdate are used in a weight ratio of 1:1:1 to form a composite catalyst, and the initiators are selected from acetonitrile, dimethylformamide, and dimethylacetamide in a weight ratio of 1 :1:2 composite initiator. The gaseous oxidant is passed into the silicon carbide ceramic plate microchannel reactor, the gaseous oxidant is oxygen+air, and the consumption of the gaseous oxidant (according to O 2 The molar weight of the form) is 25±2% of the mass of crotonaldehyde. When the pressure in the silicon carbide ceramic plate microchannel reactor reaches 1.6MPa, the crotonaldehyde, catalyst, and initiator (weight ratio 1:0.015:0.15) are mixed and pre- After heating to 30~35°C, inject it into the microchannel reactor through a metering pump, the materia...

Embodiment 2

[0057] A kind of method adopting microchannel reactor industrial production crotonic acid, carries out according to the following steps:

[0058] S1. Material oxidation process: Cobalt acetate, activated alumina, and iron phosphomolybdate are used in a weight ratio of 1:1:1 to form a composite catalyst, and the initiators are selected from acetonitrile, dimethylformamide, and dimethylacetamide in a weight ratio of 1 :1:2 composite initiator. The gaseous oxidant (air + oxygen) is passed into the silicon carbide ceramic plate microchannel reactor, and the amount of oxygen oxidant (according to O 2 The molar weight of the form) is 30±2% of the mass of crotonaldehyde. When the pressure in the silicon carbide ceramic plate microchannel reactor reaches 0.8MPa, mix and preheat the crotonaldehyde, catalyst, and initiator (weight ratio 1:0.01:0.30) After reaching 30~35°C, it is injected into the microchannel reactor through a metering pump, the material flow rate is 900±10ml / min, the ...

Embodiment 3

[0065] A kind of method adopting microchannel reactor industrial production crotonic acid, carries out according to the following steps:

[0066] S1. Material oxidation process: Cobalt acetate, activated alumina, and iron phosphomolybdate are used in a weight ratio of 1:1:1 to form a composite catalyst, and the initiators are selected from acetonitrile, dimethylformamide, and dimethylacetamide in a weight ratio of 1 :1:2 composite initiator. The gaseous oxidant (air + oxygen) is passed into the silicon carbide ceramic plate microchannel reactor, and the amount of the gaseous oxidant (according to O 2 The molar weight of the form) is 35±2% of the mass of crotonaldehyde. When the internal pressure of the silicon carbide ceramic plate microchannel reactor reaches 1.8MPa, the crotonaldehyde, catalyst, and initiator (weight ratio 1:0.015:0.20) are mixed and pre- After heating, it is injected into the microchannel reactor through a metering pump, the material flow rate is 1000±10ml...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com