Ultrasonic response type polymer fluorescent hydrogel material as well as preparation method and application thereof

A hydrogel and polymer technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of unstable shape and difficult to meet application requirements, and achieve the effect of good stability, low equipment requirements and high contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

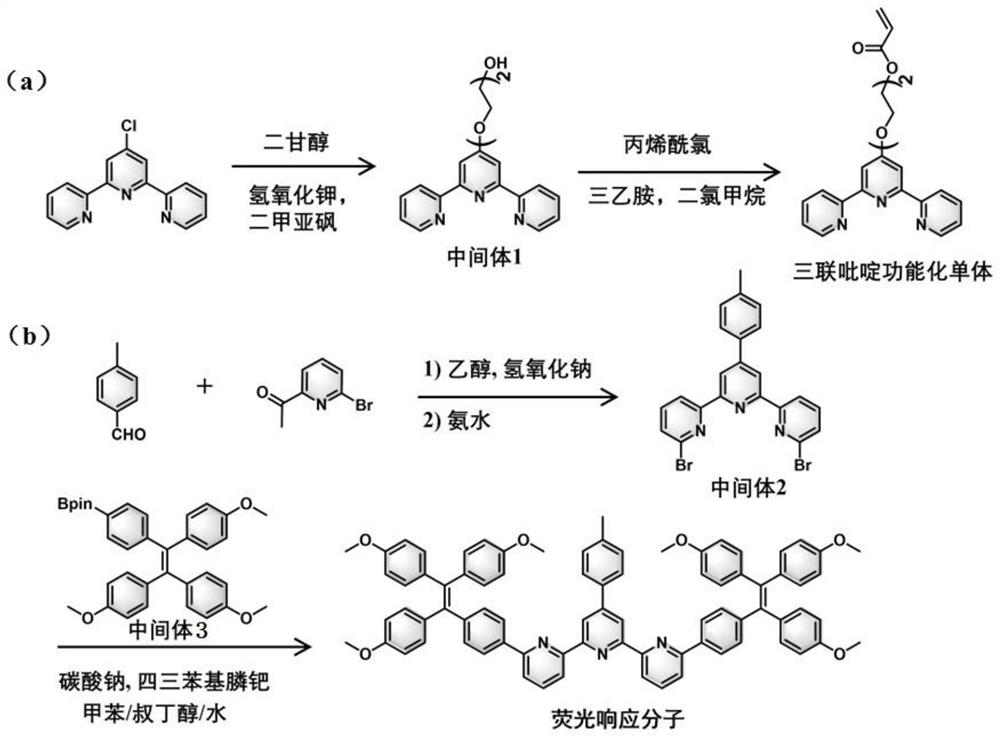

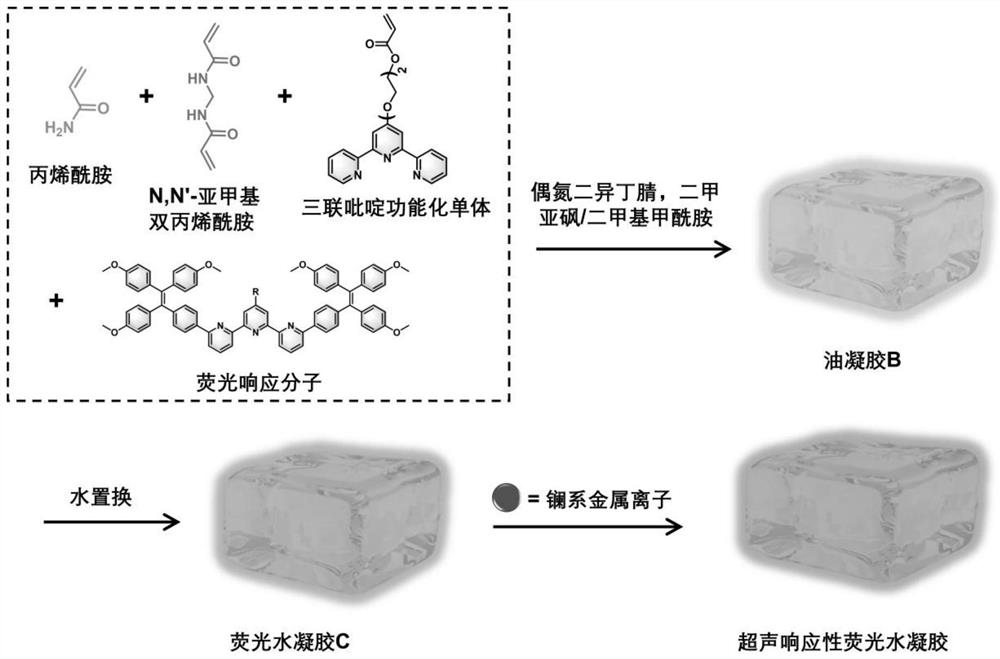

[0049] In this example, the synthesis route of the ultrasonic responsive polymer fluorescent hydrogel material is as follows: figure 2 shown.

[0050] Mix 1.5g of acrylamide (AAm), 10mg of the above-mentioned terpyridine functionalized monomer, 1mg of the above-mentioned fluorescent response molecule, 15mg of N,N'-methylenebisacrylamide (MBAA), 1.2mg of azobisisobutyronitrile (AIBN ) was added to 6.2mL dimethyl sulfoxide, and a transparent and uniform gel prepolymer solution A was obtained after shaking and dissolving;

[0051] At room temperature, inject the gel pre-polymerization solution A into a mold with a thickness of 1mm, and then transfer it to a 60°C oven to polymerize into a gel for 6 hours to obtain an oil gel B;

[0052] Transfer oil gel B to 15mL deionized water and soak for 20min, solvent replacement three times to obtain fluorescent hydrogel C;

[0053] Finally, the fluorescent hydrogel C was soaked in 0.1M europium nitrate solution for coordination for 15 mi...

Embodiment 2

[0060] In this example, the amount of fluorescent responsive molecules added was 0.6 mg, and other parameters and methods were the same as those in Example 1 to prepare an ultrasound-responsive polymer fluorescent hydrogel material.

[0061] Such as Figure 5 As shown, the ultrasound-responsive polymer fluorescent hydrogel material prepared in this example, when ultrasonically applied, the fluorescence intensity ratio at 500nm and 615nm gradually decreased until the equilibrium state was reached after 35 minutes of ultrasonication. At the same time, the hydrogel material always maintains a stable shape during the ultrasonic process, with good stability, and the fluorescence emission changes from light yellow to light red fluorescence, showing obvious changes visible to the naked eye.

Embodiment 3

[0063] In this example, the amount of fluorescence responsive molecules added was 0.2 mg, and other parameters and methods were the same as in Example 1 to prepare an ultrasonic responsive polymer fluorescent hydrogel material.

[0064] Such as Figure 5 As shown, the ultrasound-responsive polymer fluorescent hydrogel material prepared in this example, when ultrasonically applied, the fluorescence intensity ratio at 500nm and 615nm gradually decreased until the equilibrium state was reached after 20 minutes of ultrasonication. At the same time, the hydrogel material always maintains a stable shape during the ultrasonic process, with good stability, and the fluorescence emission changes from light orange to bright red fluorescence, showing obvious changes visible to the naked eye.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com