Cobalt-based catalyst as well as preparation method and application thereof

A cobalt-based catalyst and catalyst technology, which are applied in catalyst activation/preparation, hydroxyl compound preparation, chemical instruments and methods, etc., can solve the problems of high reaction temperature and operating pressure, small application prospects and harsh reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

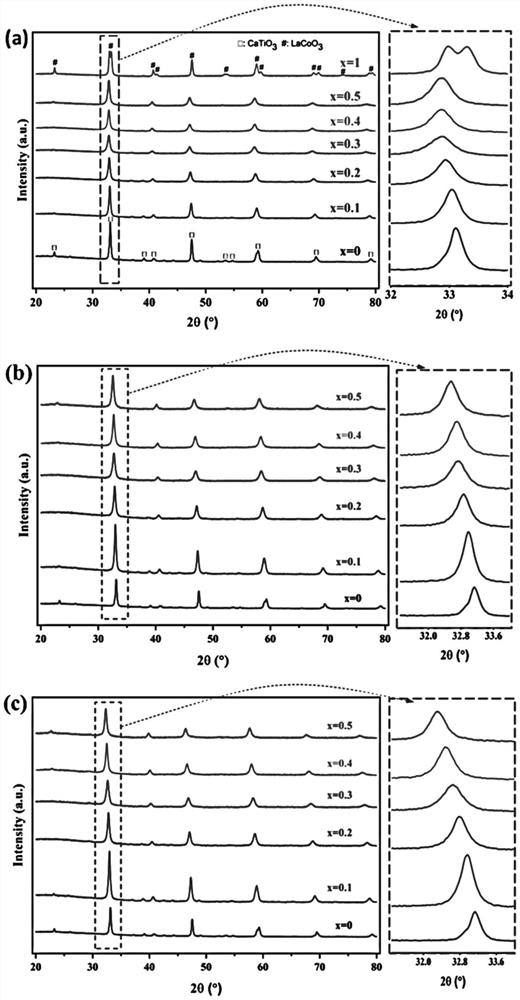

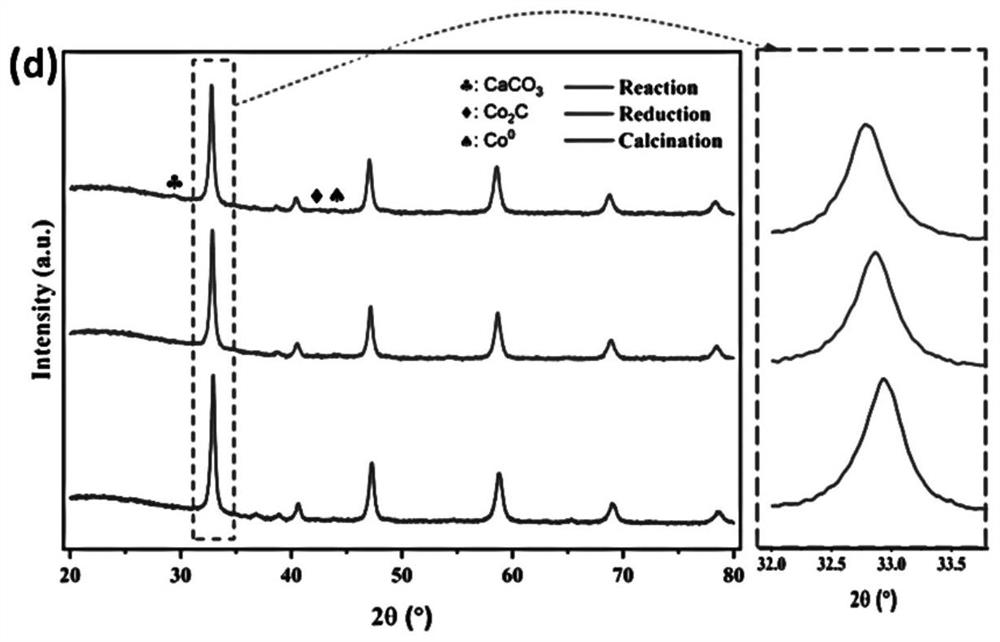

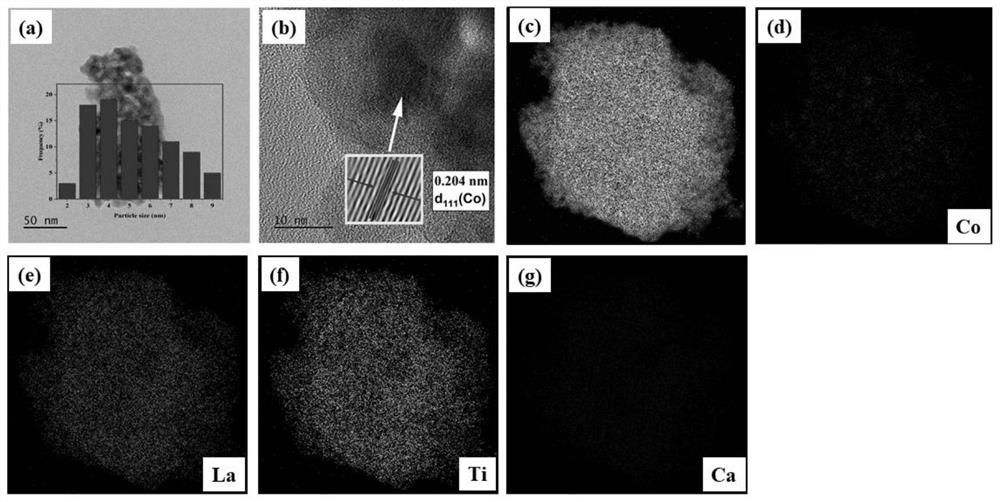

[0043] The mixed salt solution was prepared according to the molar ratio of calcium nitrate, lanthanum nitrate, tetrabutyl titanate, cobalt nitrate, citric acid and ethylene glycol in a ratio of 0.7:0.3:0.7:0.3:2.4:0.48; the catalyst Ca was obtained through step 1A 0.7 La 0.3 Ti 0.7 Co 0.3 O 3 ; Obtain Co / La through step 2A reduction 2 O 3 -CaTiO 3 catalyst. Test conditions 3A for carbon monoxide hydrogenation to produce low-carbon alcohols.

Embodiment 2

[0045] According to the molar ratio of calcium nitrate, yttrium nitrate, tetrabutyl titanate, cobalt nitrate, citric acid and ethylene glycol, the molar ratio is 0.7: 0.3: 0.7: 0.3: 2.4: 0.48 to prepare mixed salt solution; the catalyst Ca is obtained through step 1B 0.7 Y 0.3 Ti 0.7 Co 0.3 O 3 ; Obtain Co / Y through step 2A reduction 2 O 3 -CaTiO 3 catalyst. Test conditions 3A for carbon monoxide hydrogenation to produce low-carbon alcohols.

Embodiment 3

[0047] According to the molar ratio of calcium nitrate, cerium nitrate, tetrabutyl titanate, cobalt nitrate, citric acid and ethylene glycol, the molar ratio is 0.7:0.3:0.7:0.3:2.4:0.48; 0.7 Ce 0.3 Ti 0.7 Co 0.3 O 3 . Co / CeO is obtained by reduction in step 2A 2 -CaTiO 3 catalyst. Test conditions 3A for carbon monoxide hydrogenation to produce low-carbon alcohols.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com