Method for preparing n-octanal

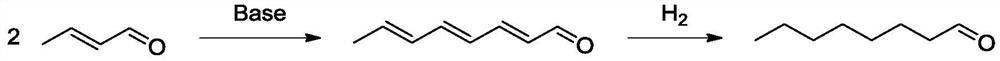

A technology of n-octyl aldehyde and octatrienal, which is applied in the direction of carbon-based compound preparation, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problem that it is difficult to improve the conversion rate of crotonaldehyde, so as to improve the reaction conversion rate and The effect of selectivity, novel synthetic route and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Preparation of catalyst A: carbon nanotubes, silver nitrate, cadmium nitrate, and lead nitrate were mixed in water according to a mass ratio of 100:1:1:1, immersed at 25°C for 24 hours, and then calcined at 500°C for 8 hours in a nitrogen atmosphere. Then, the obtained mixture is uniformly mixed with sodium hydroxide, and the mass ratio of sodium hydroxide to carbon nanotubes is 1:10 to obtain catalyst A.

Embodiment 2-5

[0054] Embodiment 2-5 (abbreviated as S2-S5) and comparative example 1-4 (abbreviated as D1-D4)

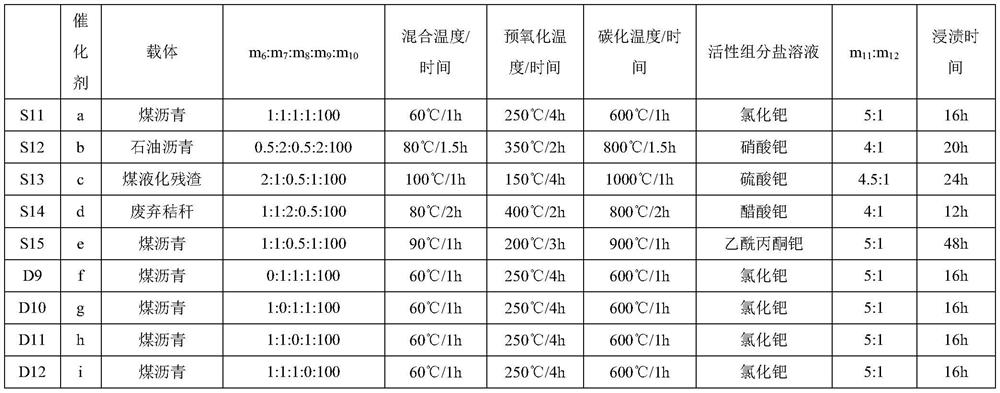

[0055] The preparation process parameters of condensation catalyst B-I are shown in Table 1. The composition of the condensation catalyst is shown in Table 2.

[0056] Table 1 Condensation catalyst B-I preparation process parameters

[0057] catalyst carrier Active ingredient m 1 :m 2 :m 3 :m 4 :m 5

Immersion temperature / time Roasting temperature / time S2 B Graphene Zinc oxide 100:5:1:1:0.5 30℃ / 48h 400℃ / 4h S3 C carbon nanocloth Calcium Oxide 100:20:1:1:0.8 40℃ / 12h 600℃ / 6h S4 D activated carbon Calcium hydroxide 100:10:0.8:0.5:1 30℃ / 24h 500℃ / 4h S5 E carbon nanotubes sodium oxide 100:15:1:0.8:1 30℃ / 36h 600℃ / 5h D1 F carbon nanotubes sodium hydroxide 100:10:0:1:1 25℃ / 24h 500℃ / 8h D2 G carbon nanotubes sodium hydroxide 100:10:1:0:1 25℃ / 24h 500℃ / 8h D3 H carbon nanotubes sodium...

Embodiment 6-10

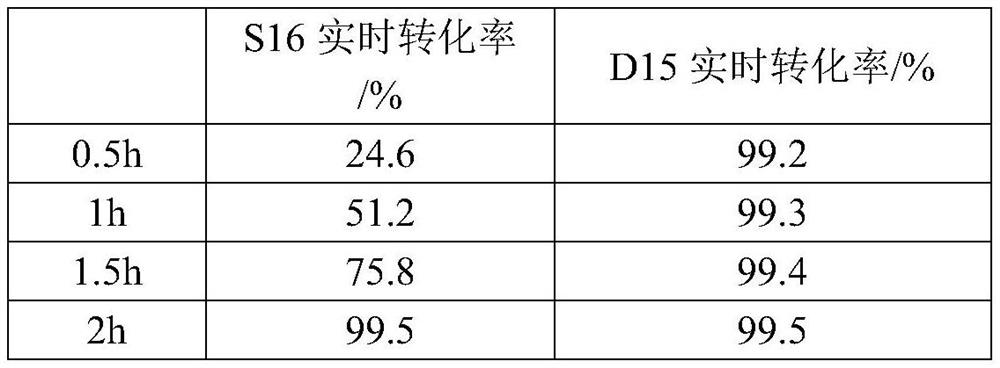

[0061] Example 6-10 (S6-S10 for short) and Comparative Example 5-8 (D5-D8 for short)

[0062] Using crotonaldehyde as raw material, 2,4,6-octatrienal was prepared by gas-phase condensation reaction. The reactor for the gas phase condensation reaction is in the form of a fixed bed. The gas-phase condensation reaction of crotonaldehyde is carried out under a certain catalyst concentration, certain temperature and residence time to obtain 2,4,6-octatrienal. The technical parameters of the condensation reaction are shown in Table 3. The condensation reaction results are shown in Table 4.

[0063] Table 3 Condensation reaction process parameters

[0064] Condensation catalyst Condensation reaction temperature / residence time Condensation catalyst dosage / wt% S6 A 250℃ / 1h 0.1 S7 B 180℃ / 2h 1.0 S8 C 360℃ / 0.5h 0.05 S9 D 300℃ / 3h 0.1 S10 E 250℃ / 2h 2.0 D5 F 250℃ / 1h 0.1 D6 G 250℃ / 1h 0.1 D7 H 250℃ / 1h 0.1 D8 I 250℃...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com