Polyurethane hot melt adhesive film and preparation method thereof

A technology of polyurethane hot melt adhesive and diisocyanate, which is applied in the direction of polyurea/polyurethane adhesive, adhesive, film/sheet adhesive, etc., which can solve the problem of reducing bonding strength, affecting bonding effect, and low solid content To achieve the effect of ensuring the bonding effect, reducing the energy consumption of sizing, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention also provides the preparation method of the polyurethane hot-melt adhesive film described in the above scheme, comprising the following steps:

[0030] (1) Mix polyol, diisocyanate and catalyst to carry out the first reaction, then add the first chain extender to carry out the second reaction, then add the second chain extender to carry out the third reaction, and then add the crosslinking agent to carry out the fourth reaction , and finally add a neutralizing agent to obtain a polyurethane prepolymer;

[0031] (2) After coating the polyurethane prepolymer on the film-forming substrate, drying and peeling are performed in sequence to obtain a polyurethane hot-melt adhesive film.

[0032]In the present invention, the polyol, diisocyanate and catalyst are mixed to carry out the first reaction, then the first chain extender is added to carry out the second reaction, then the second chain extender is added to carry out the third reaction, and the cross...

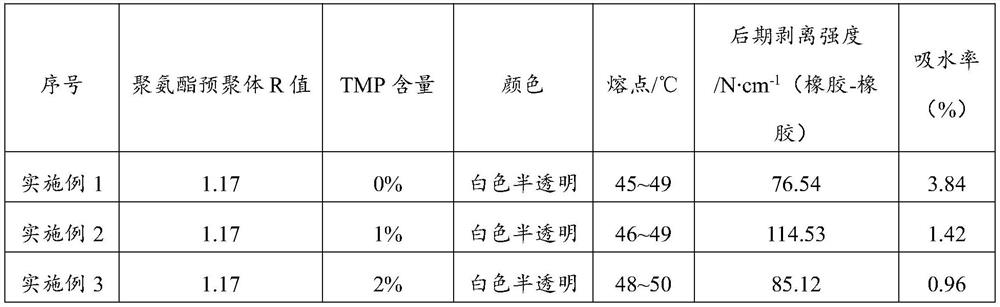

Embodiment 1

[0036] (1) Put 60 g of polyethylene adipate diol (PDA, number average molecular weight 3000) and 15 g of polycarbonate diol (PCDL, number average molecular weight 3000) at 105°C for vacuum drying Vacuum dewatering in the box for 6h; put the dewatered polyol into the reaction vessel, then add 16g isophorone diisocyanate (IPDI), 3.3g hexamethylene diisocyanate (HDI) and 0.1g dilaurin in sequence Dibutyltin acid catalyst, set the temperature of the water bath to 75°C, the speed of rotation is 400r / min, and react for 2h; then add 4g of 1,4-butanediol (BDO) and react for 1h;

[0037] (2) 1 g of dimethylolpropionic acid (DMPA) was dissolved in N-methylpyrrolidone of equal quality, added to the reaction vessel, and the reaction was kept under stirring for 4h, during which the viscosity was adjusted to 8000~15000mPa·s with acetone;

[0038] (3) reduce the temperature of the reaction vessel to 45°C, add 0.1 g of triethylamine to the reaction vessel, keep stirring for 1 hour, and adjust...

Embodiment 2

[0041] (1) Put 75g of poly-1,4-butanediol adipate diol (PBA, number average molecular weight 3000) in a vacuum drying box at 105°C to remove water in vacuum for 6 hours, and remove the polyol after water removal. Put it into the reaction vessel, then add 20g isophorone diisocyanate (IPDI) and 0.1g dibutyltin dilaurate catalyst in turn, set the water bath temperature to 75°C, the rotating speed to 450r / min, and react for 1h; then add 3.3g of 1,4-Butanediol (BDO), reacted for 1h;

[0042] (2) 1 g of dimethylolpropionic acid (DMPA) was dissolved in N-methylpyrrolidone of equal quality, added to the reaction vessel, and the reaction was kept under stirring for 2h, during which the viscosity was adjusted to 8000~15000 mPa·s with acetone;

[0043] (3) 0.75g of trimethylolpropane (TMP) was added to the reaction vessel, kept stirring for 2h, during which the viscosity was adjusted to 8000~15000mPa·s with acetone;

[0044] (4) reduce the temperature of the reaction vessel to 42°C, add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com