Photocatalyst as well as preparation method and application thereof

A photocatalyst, zinc chloride technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. The problems of photocatalytic efficiency and low utilization rate of visible light band have achieved broad application prospects, high practical value, and the effect of reducing catalyst costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a photocatalyst provided in the present embodiment, comprising the following steps:

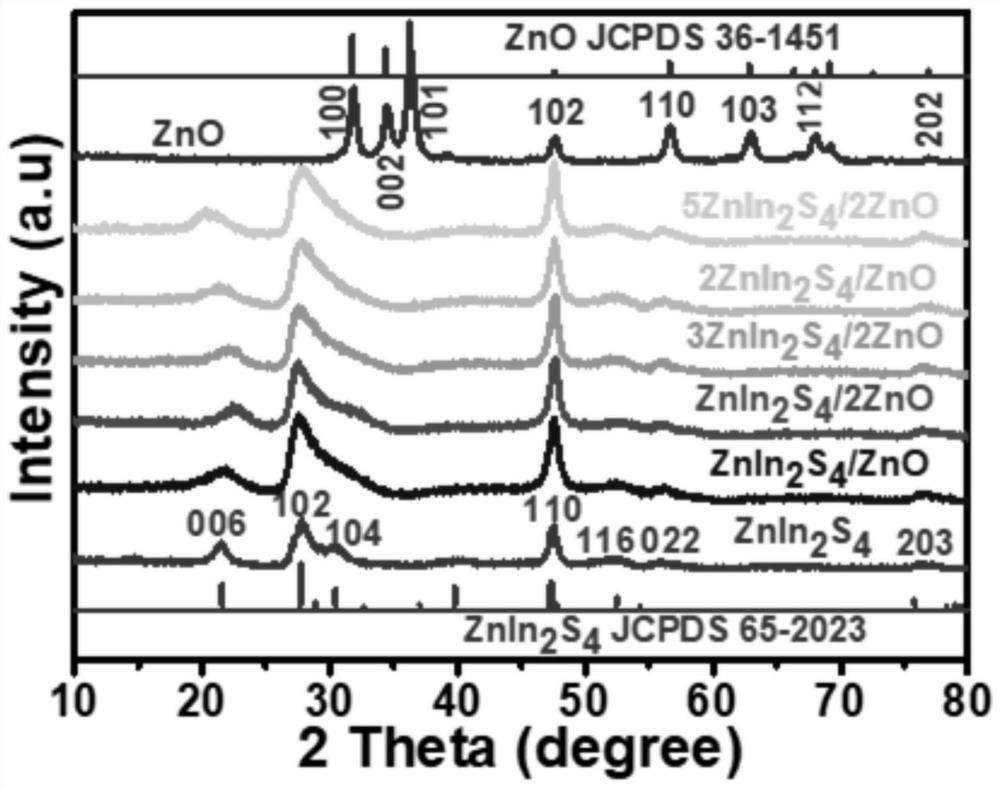

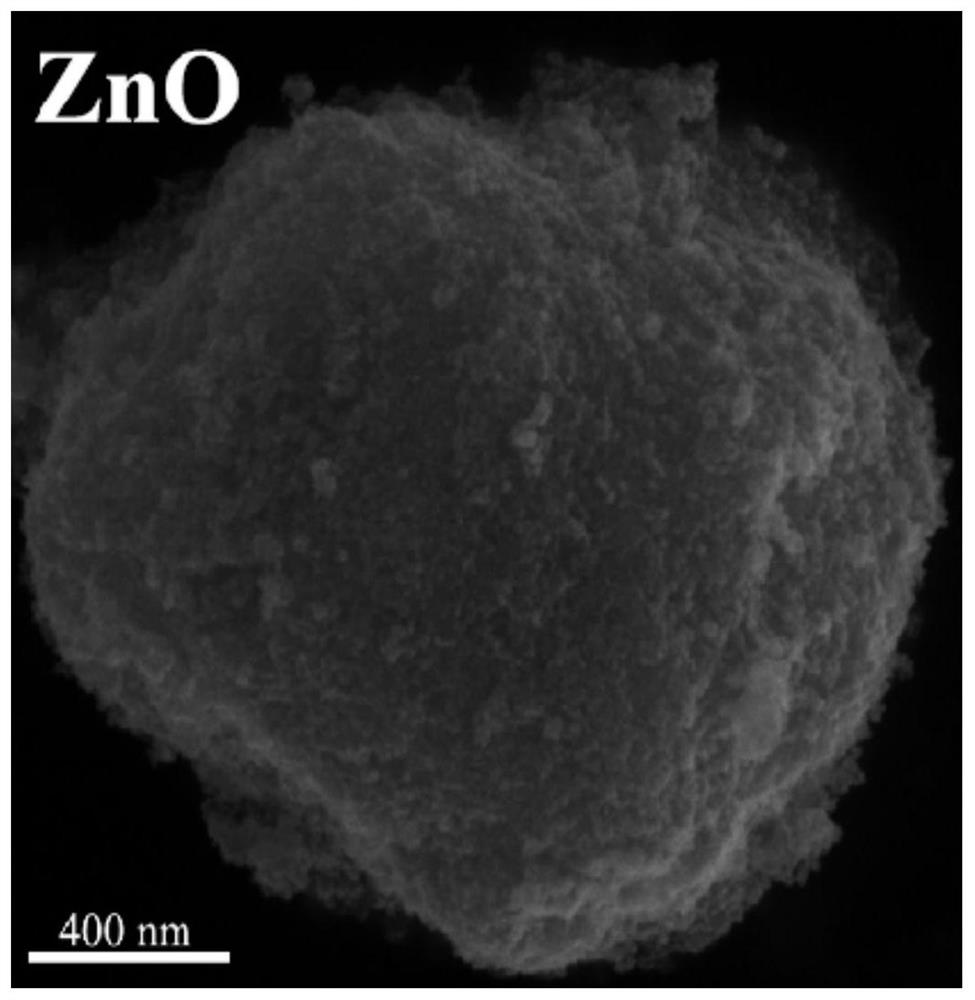

[0029] S1: Prepare ZnO nanoparticles, weigh 4.59gZnAc 2Dissolve in 25 ml of methanol solution, continuously stir at 60 °C for 30 minutes to form a suspension, add 50 ml of potassium hydroxide solution (1M) to the suspension, continue stirring at 60 °C for 2 hours to form a white precipitate, cool to room temperature, filter, wash several times with ultrapure water, and then vacuum dry at 70 °C in a vacuum drying box until overnight to obtain ZnO nanoparticles.

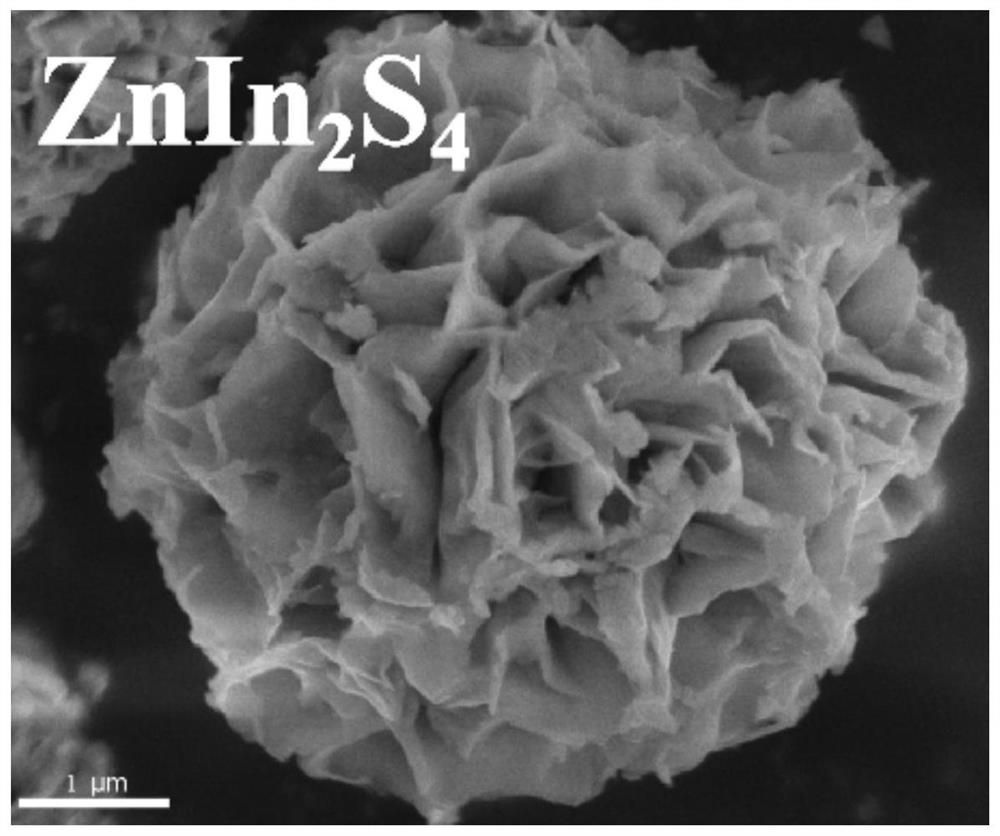

[0030] S2: Prepare ZnIn 2 S 4 Nanosheets, using a one-step hydrothermal synthesis method, weigh 0.17 g of zinc chloride (ZnCl 2 ), 0.73 g indium trichloride (InCl) tetrahydrate 3 ·4H 2 O) and 0.38g thioacetamide (TAA) sonically dissolved into 25ml of ethylene glycol, continuously stirred at room temperature for 30 minutes, forming a mixture, the mix of the step was transferred to a 50ml polytetrafluoroethylen...

Embodiment 2

[0038] The difference between the present embodiment and Example 1 is:

[0039] S3: Prepare 2ZnIn 2 S 4 / ZnO heterojunction nanomaterials, using a one-step hydrothermal synthesis method, weighing 0.34 g of zinc chloride, 1.46 g of indium trichloride tetrahydrate and 0.76 g of thioacetyl dissolved into 25 ml of ethylene glycol, continuously stirred at room temperature for 30 minutes, to form a mixture, the ZnO nanoparticles prepared in step S1 (weighed 0.1 g) dispersed in the mixed liquid of this step, sonically dispersed for 30 minutes at room temperature, and then transferred to a 50 ml polytetrafluoroethylene lined autoclave, Heat at a temperature of 120 °C for 2 hours to obtain the pellet, and then centrifuge, wash, and separate the pellet of this step, and then dry it in vacuo for 12 hours to obtain 2ZnIn 2 S 4 / ZnO heterojunction nanomaterials as photocatalysts.

[0040] The present embodiment also provides a photocatalyst, the photocatalyst is prepared using a preparation me...

Embodiment 3

[0042] The difference between the present embodiment and Example 1 is:

[0043] S3: Prepare ZnIn 2 S 4 / 2ZnO heterojunction nanomaterials, using a one-step hydrothermal synthesis method, weighing 0.17g zinc chloride, 0.73g indium trichloride tetrahydrate and 0.38g thioacetyl dissolved into 25ml of ethylene glycol, continuously stirred at room temperature for 30 minutes, to form a mixture, the ZnO nanoparticles prepared in step S1 (weighed 0.2g) dispersed in the mixed liquid in this step, sonically dispersed for 30 minutes at room temperature, and then transferred to a 50ml polytetrafluoroethylene lined autoclave, Heat at a temperature of 120 °C for 2 h to obtain the pellet, and then centrifuge, wash, and separate the pellet of this step, and then dry it in vacuo for 12 h to obtain ZnIn 2 S 4 / 2ZnO heterojunction nanomaterials as photocatalysts.

[0044] The present embodiment also provides a photocatalyst, the photocatalyst is prepared using a preparation method such as the above-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com