Separation and purification process of high-activity phytolectin

A plant lectin, separation and purification technology, applied in the fields of plant peptides, organic chemistry, peptide preparation methods, etc., can solve the problems of purity and activity detection, increase of uncertainty rate, unavoidable, etc., and achieve effective removal of impurities and easy production. Scale, the effect of scaling up production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Example 1: Separation and purification extraction of PHA-L

[0077] Pre-treatment:

[0078] Remove the well-preserved red kidney beans from the refrigerator at 2-8 °C for weighing, weigh about 1000±20g, add pure water to soak at room temperature for 4-6h, peel the peeling machine, add 4 mL 20 mM NaAC-HAc (buffer, pH = 4.5-7.4) per gram of red kidney beans, use the wall breaker to break the wall, and the solution after the wall is placed on a stirrer in the refrigerator at 2-8 °C for 300-400rpm4h or more. After thorough agitation, the slurry was first frozen by at least 12h, and re-thawed, and then the pH of the solution was adjusted using 2M dilute hydrochloric acid to 4.5-5.5, preferably 5.0, and the solution was divided into centrifuges into centrifuges, centrifuged at a centrifugal force of 14000g or more, centrifuged at a centrifugal temperature of 4 ° C for 10-30min, the supernatant was taken.

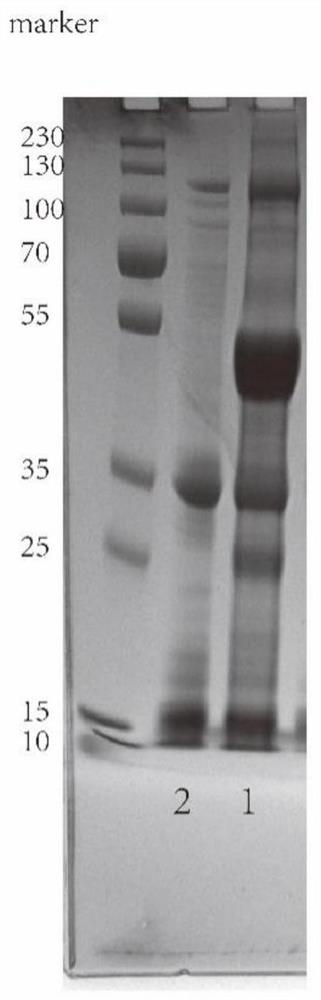

[0079] Figure 1 Is a different treatment after the supernatant electropho...

Embodiment 2

[0096] Example 2: PBMC cell stimulation activity verification

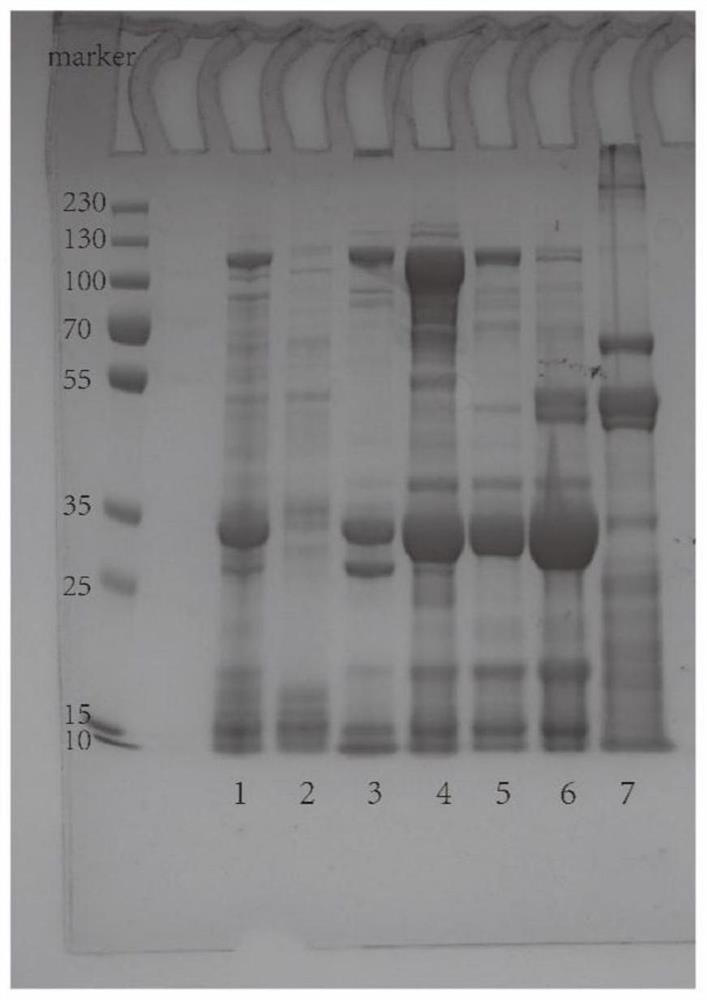

[0097] The activities of the elution gradients of the pretreatment step, SP ion exchange chromatography (20 mM NaAC-HAc, pH5.0±0.1, 50 mM NaCl, 150 mM NaCl) and the DEAE ion exchange chromatography purification step (20 mM Tris, pH8.0±0.1, 20 mM NaCl, 70 mM NaCl, 1 M NaCl) were compared in activity, as follows:

[0098] The slurry, SP ion exchange chromatography and DEAE ion exchange chromatography purification step of the pretreatment step were taken separately, and the protein concentration (PHA) determined by BCA was the starting concentration, diluted with endotoxin-free PBS to a final concentration of 1ug / 25uL, 0.2ug / 25uL.

[0099] Add 25 ul of the above diluted eluent to a 2 ml centrifuge tube free of endotoxins, respectively.

[0100]Take one tube of frozen PBMC cells for resuscitation, prepare a cell suspension (1 M / mL) and add 600 uL of cell suspension to the centrifuge tubes of the above 2 ml. Gently mix wel...

Embodiment 3

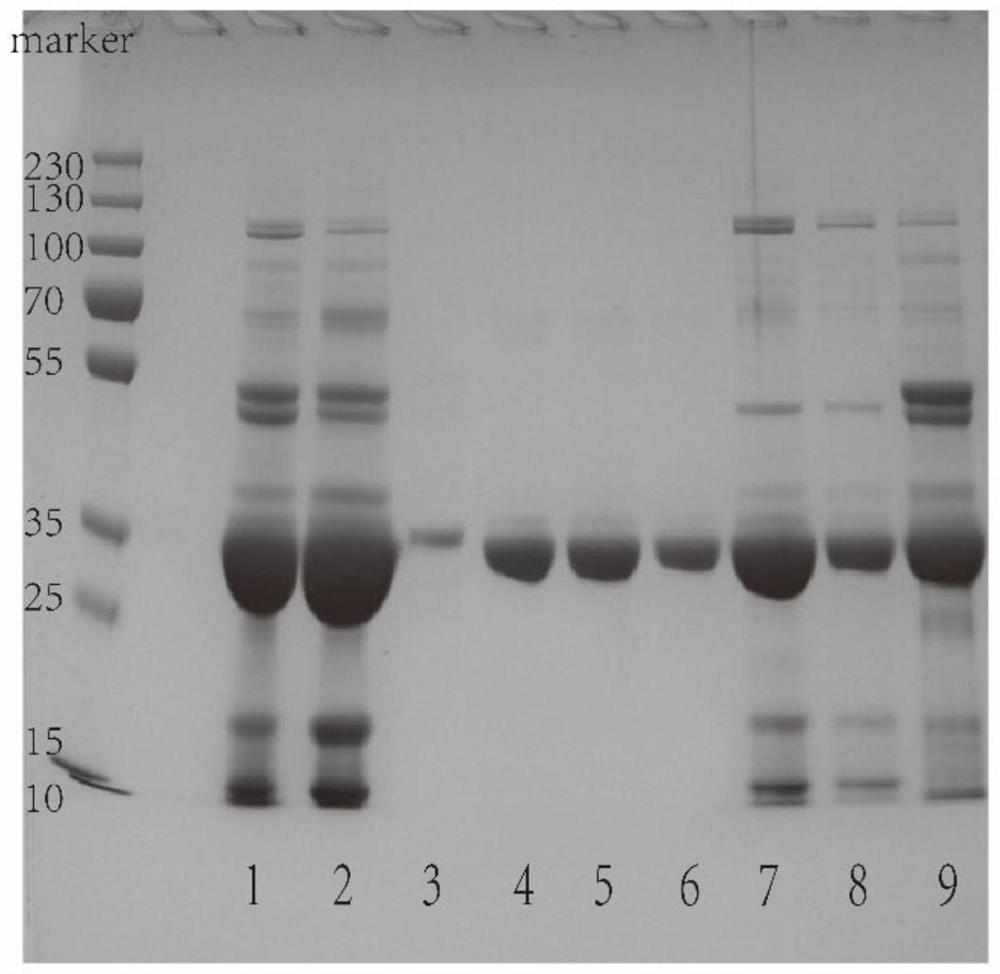

[0111] Example 3: Effect of different preparation processes on PHA-L purity and yield

[0112] The pretreatment process of Example 1 is compared with a conventional PHA purification method (fractional precipitation containing ammonium sulfate).

[0113] The conventional PHA purification method is as follows:

[0114]Step 1: Pre-processing.

[0115] With step one of the present invention, kidney beans do not peel, centrifugation to obtain supernatant.

[0116] Step 2: Ammonium sulfate graded precipitation.

[0117] 1) According to the above supernatant volume, the calculation requires the addition of solid ammonium sulfate to a saturation of 40%. And while adding supernatant while stirring to dissolve, after dissolution placed at room temperature continue to stir for 10min, stand for 1h, the solution is divided into centrifuge tubes for equilibrium, and then use high-speed centrifuge to set the centrifugal force of 10000g, centrifuge at a centrifugal temperature of 4 °C for 30min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com