Polyurethane hydrogel of composite nanoparticles and application

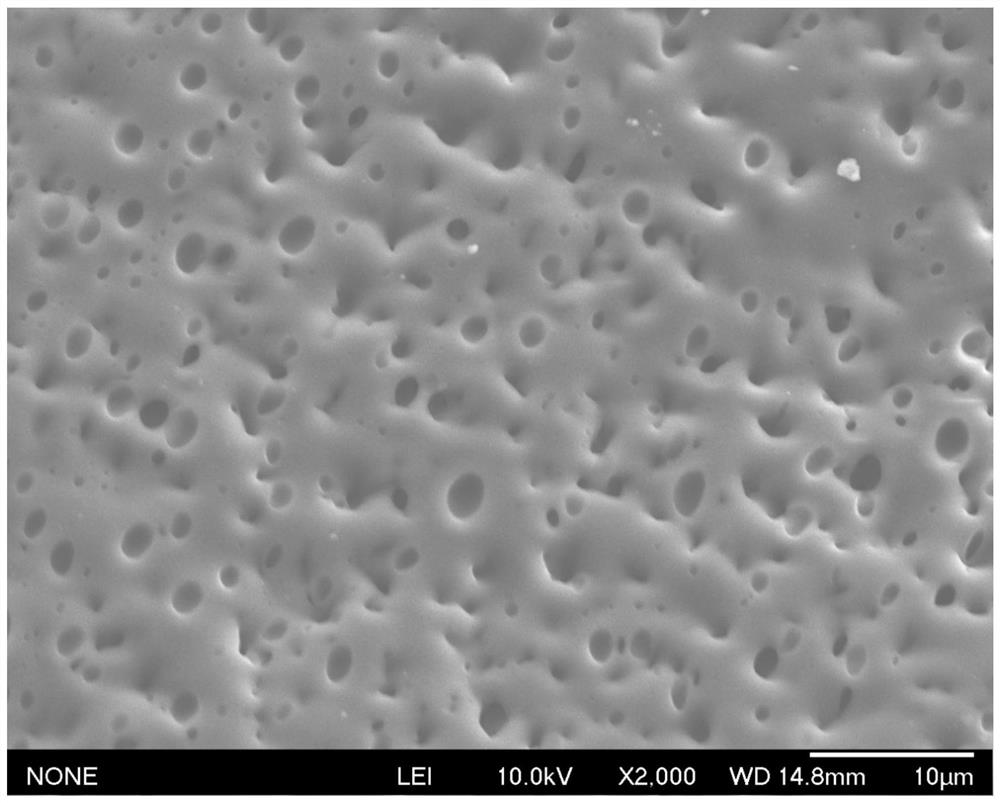

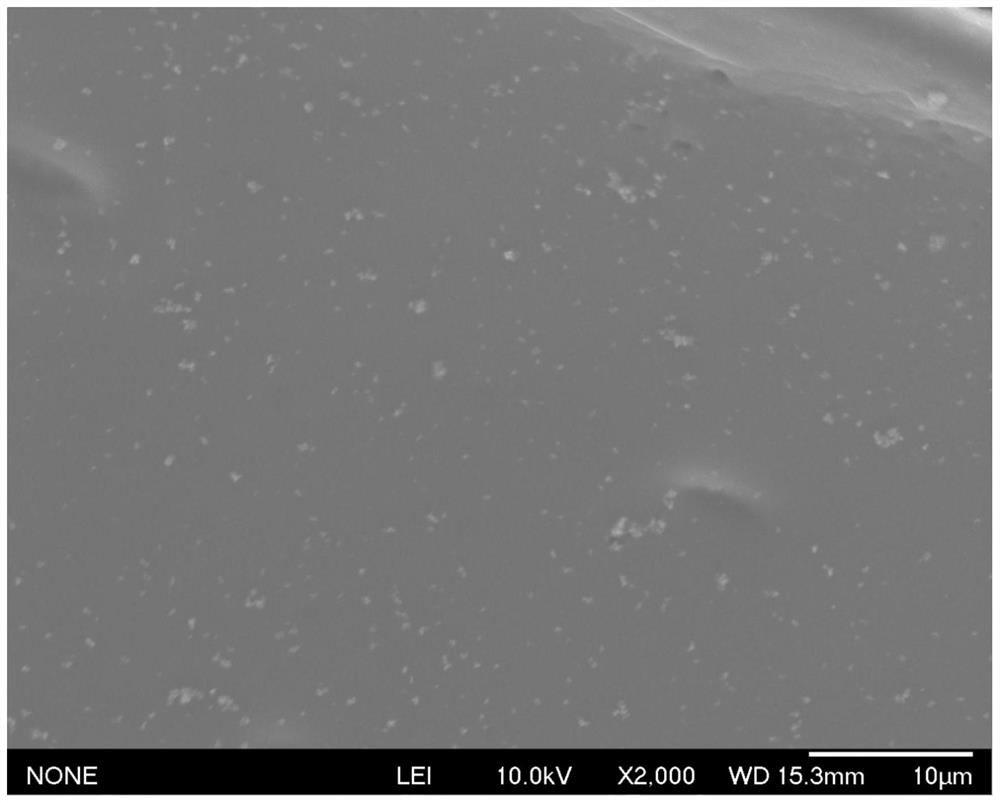

A technology of composite nanoparticles and polyurethane, which is applied in the field of hydrogel, can solve the problems of difficult attachment of microorganisms, slow growth and reproduction, small specific surface area, etc., and achieve easy transfer and homogenization, suitable for large-scale production, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] In some preferred embodiments, the polyurethane hydrogel preparation method of the kind of composite nanoparticles comprises the following steps:

[0051] Step 1: Dehydrate the polyol vacuum until the water content is below 0.1%, and then after dehydration, the polyol and diisocyanate are uniformly mixed in the reaction kettle for 2-4h to obtain the first component;

[0052] Step 2: Disperse the coupling agent with nano-inorganic particles in a solution with a volume ratio of 1:9 in distilled water and absolute ethanol, sonicate, filter, dry, and prepare surface-treated nano-inorganic particles; The blowing agent, inorganic metal catalyst, silicone oil, chain spreader, surface treated nano-inorganic particles are mixed and ultrasonically treated to obtain a second component.

[0053] Step 3: The first component is mixed with the second component, and then transported to the membrane for foaming, the temperature is 35 °C-50 °C, and the polyurethane hydrogel of the composite ...

Embodiment 1

[0062] The present embodiment provides a polyurethane hydrogel of composite nanoparticles, the raw materials prepared by weight comprise 20 parts of polyisocyanates, 50 parts of polyols, 10 parts of inorganic nanoparticles, 1 part of silicone oil, 10 parts of chain expander, 50 parts of blowing agent, 2 parts of coupling agent, 1 part of organometallic catalyst.

[0063] The preparation method of the polyurethane hydrogel of the composite nanoparticles comprises the following steps:

[0064] Step 1: The polyol is dehydrated to a water content of less than 0.1% under the condition of vacuum of -0.5MPa and a temperature of 115 °C; then the dehydrated polyol and diisocyanate are mixed in the reactor for 3h, and the reaction temperature is 75 °C to prepare the first component.

[0065] Step 2: Disperse the coupling agent with nano-inorganic particles in a solution with a volume ratio of 1:9 in distilled water and absolute ethanol, sonicate, filter, dry, and prepare surface-treated nan...

Embodiment 2

[0069]The present embodiment provides a polyurethane hydrogel of composite nanoparticles, the raw materials prepared by weight comprise 20 parts of polyisocyanates, 50 parts of polyols, 10 parts of inorganic nanoparticles, 1 part of silicone oil, 10 parts of chain expander, 50 parts of blowing agent, 2 parts of coupling agent, 1 part of organometallic catalyst.

[0070] The preparation method of polyurethane hydrogel of composite nanoparticles, comprising the following steps:

[0071] Step 1: The polyol is dehydrated to a water content of less than 0.1% under the condition of vacuum of -0.5MPa and a temperature of 115 °C; then the dehydrated polyol and diisocyanate are mixed in the reactor for 3h, and the reaction temperature is 75 °C to prepare the first component.

[0072] Step two: the coupling agent and nano-inorganic particles dispersed in distilled water and anhydrous ethanol volume ratio of 1:9 solution, sonication, filtration, drying, preparation of surface treatment of na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com