Coating liquid composition, coating liquid, film-coated rubber plug and preparation method of film-coated rubber plug

A technology of composition and coating liquid, applied in the directions of coating, transportation and packaging, type of packaging items, etc., can solve the problems of weak adhesion of film materials, easy film falling off, etc., achieve low surface friction coefficient, reduce particle size, etc. Effects of contamination, reliable biosecurity and biostability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0054] According to a preferred embodiment of the present invention, the conditions for the ultraviolet light curing include: the power of the medium pressure mercury lamp is 300-3000W, the irradiation distance is 10-50cm, and the curing time is 10-360s. The power is 1500-2000W, the irradiation distance is 15-30cm, and the curing time is 30-180s. In the present invention, the ultraviolet light curing can be carried out in an inert atmosphere or an oxygen-containing atmosphere, and in order to reduce the production cost, the ultraviolet light curing is carried out in the air. In this preferred embodiment, the rubber stopper cured by ultraviolet light has a lower surface friction coefficient, and has better anti-ultraviolet, chemical resistance and aging resistance.

[0055] Preferably, the material of the rubber stopper to be sprayed is selected from at least one of isoprene rubber, butyl rubber and halogenated butyl rubber.

[0056] According to the present invention, in step...

Embodiment 1

[0089]The material of the film-coated rubber plug in this embodiment is bromobutyl rubber, which includes preparing a coating liquid composition to obtain a coating liquid, coating the coating liquid on the surface of the cleaned and dried rubber plug, and curing the coating A step of.

[0090] Wherein, the composition of the coating composition is: 100 g of ethyl orthosilicate, 176 g of ethanol, 87 g of water, organosilicon (methyltriethoxysilane and diphenyldimethoxysilane, and methyltriethoxysilane) The weight ratio of silane and diphenyldimethoxysilane is 1:1) 200g, coupling agent (KH-570) 100g, H-type mordenite catalyst (silicon-aluminum molar ratio is 13, cylindrical) 1g, Photoinitiator (2-hydroxy 2-methyl-1-phenyl-1-propyl ketone) 25g.

[0091] The preparation process of the film-coated rubber plug of the present embodiment, the specific steps are as follows:

[0092] (1) Carry out contact reaction with ethyl orthosilicate, ethanol, water, organosilicon, coupling agen...

Embodiment 2-7

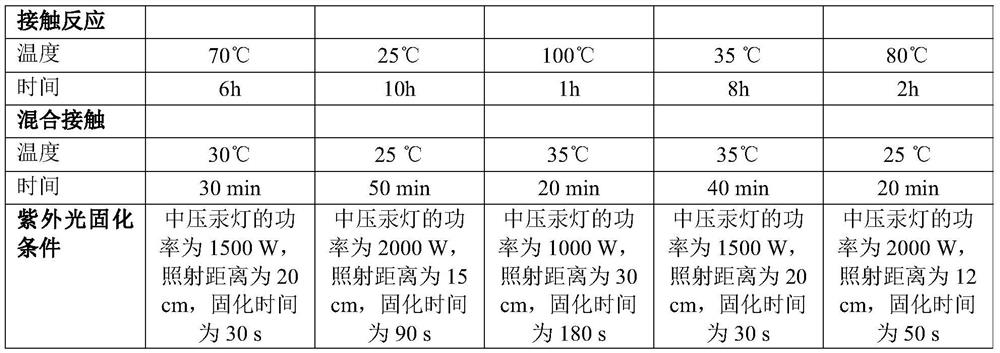

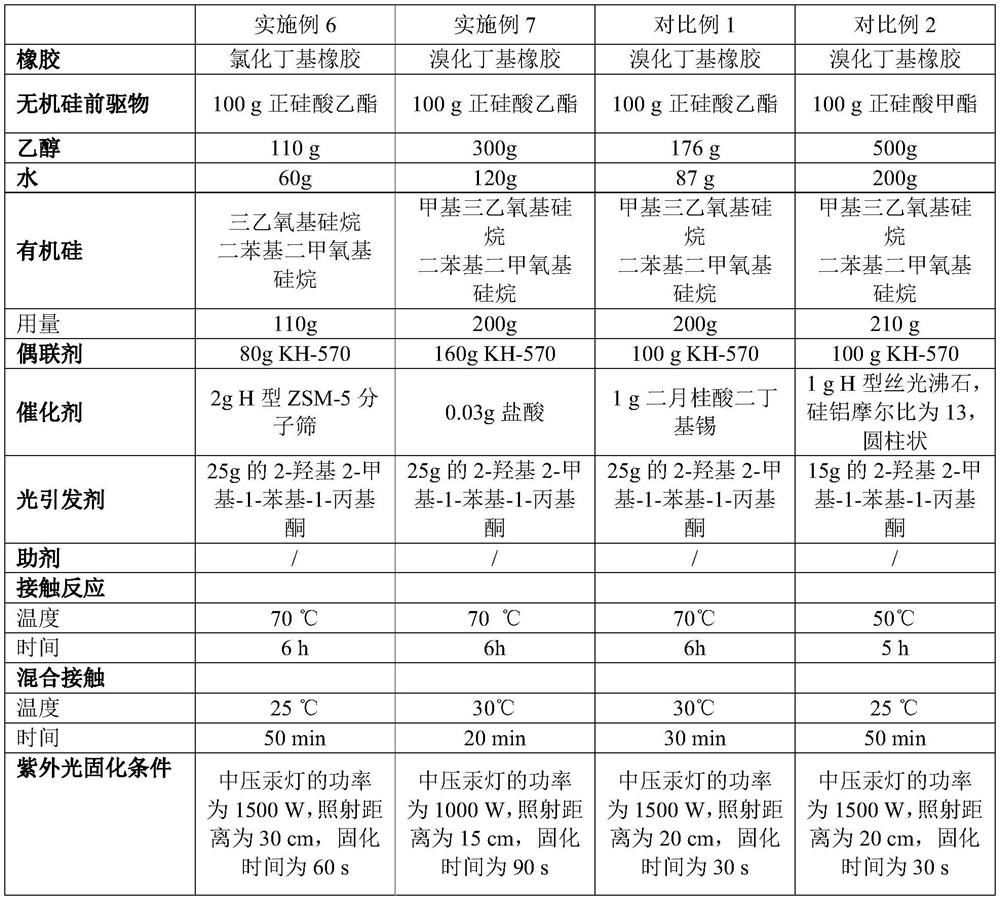

[0101] This example is to illustrate the use of the coating liquid composition of the present invention to prepare a coating liquid, and the use of the coating liquid to prepare a film-coated rubber stopper.

[0102] The film-coated composition, the coating solution and the film-coated rubber stopper were prepared in the same manner as in Example 1, except that the components and component contents in the film-coated composition, the components in the coating solution and the The component contents and preparation conditions were changed, as shown in Table 1 and Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com