Annealed Si-based InN nanorod heterojunction and preparation method and application thereof

An annealing treatment and nano-pillar technology is applied in the field of InN nano-pillars to achieve the effects of saving preparation cost, reducing migration distance and reducing recombination probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of an annealed Si-based InN nano-pillar heterojunction, comprising the following steps:

[0038] (1) Substrate selection: n-type Si substrate (conductivity <0.005Ω) is used.

[0039] (2) Growth of InN nanocolumns: the molecular beam epitaxy growth process is used, the substrate temperature in step (1) is controlled to be 400 °C, the substrate rotation speed is 10 r / min, and the In beam equivalent pressure is 1.43×10 -7 Torr, the nitrogen flow rate was 2sccm, the plasma source power was 400W, and the growth time was 2h.

[0040] (3) Preparation method of InN nano-pillar heterojunction: chemical vapor deposition process is used to deposit the prepared InN nano-pillars in N 2 Annealed at 500 °C for 5 min in a protected sulfur atmosphere to obtain InN / In 2 S 3 Nanopillar heterojunction.

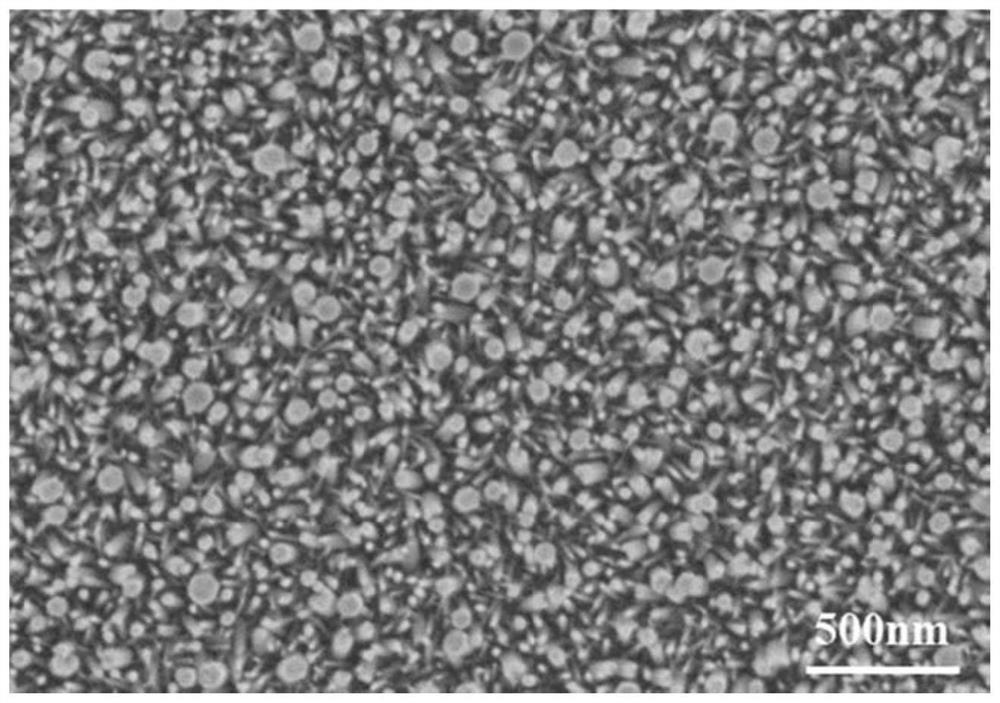

[0041] like figure 1 As shown, the SEM top view of the Si-based InN nano-pillar heterojunction annealed in a sulfur atmosphere in this example.

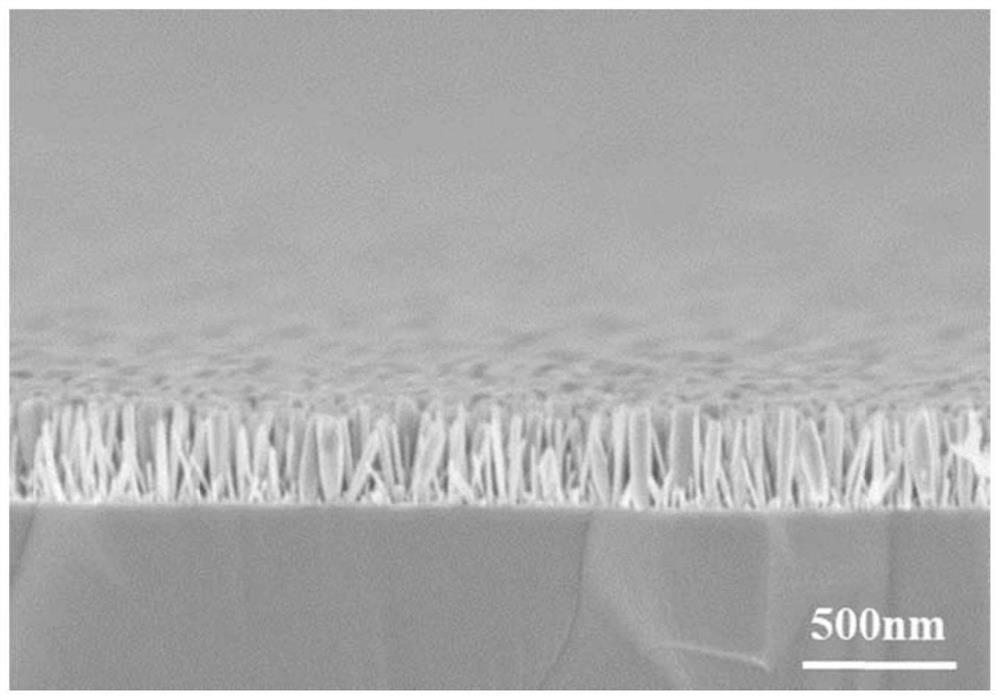

[0042] like f...

Embodiment 2

[0045] A preparation method of an annealed Si-based InN nano-pillar heterojunction, comprising the following steps:

[0046] (1) Substrate selection: n-type Si substrate (conductivity <0.005Ω) is used.

[0047] (2) Growth of InN nanocolumns: the molecular beam epitaxy growth process is used, the substrate temperature in step (1) is controlled to be 400 °C, the substrate rotation speed is 10 r / min, and the In beam equivalent pressure is 1.43×10 -7 Torr, the nitrogen flow rate was 2sccm, the plasma source power was 400W, and the growth time was 2h.

[0048] (3) Preparation method of InN nano-pillar heterojunction: chemical vapor deposition process is used to deposit the prepared InN nano-pillars in N 2 Annealed at 500 °C for 5 min in an oxygen atmosphere under protection to obtain InN / In 2 O 3 Nanopillar heterojunction.

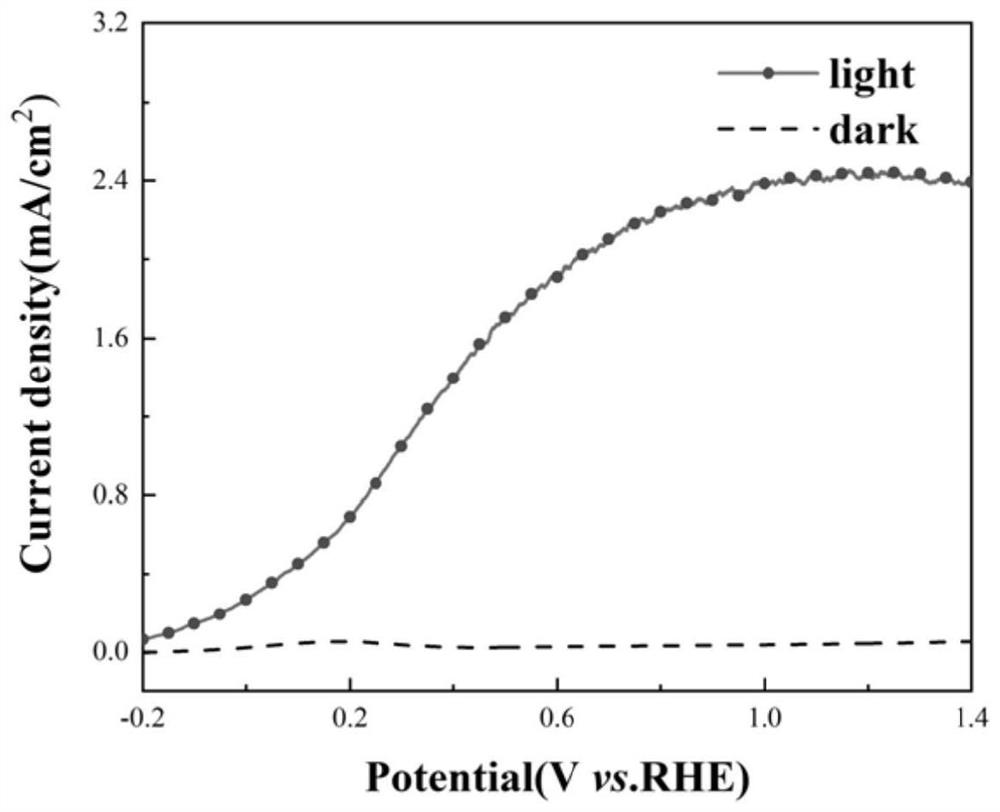

[0049]The Si-based InN nanopillar heterojunction annealed in the sulfur atmosphere of this example is used for photoelectrolysis of water: the prepared Si-...

Embodiment 3

[0051] A preparation method of an annealed Si-based InN nano-pillar heterojunction, comprising the following steps:

[0052] (1) Substrate selection: n-type Si substrate (conductivity <0.005Ω) is used.

[0053] (2) Growth of InN nanopillars: using the molecular beam epitaxy growth process, the substrate temperature in step (1) is controlled to be 400 °C, the substrate rotation speed is 10 r / min, and the In beam equivalent pressure is 1.43×10 -7 Torr, the nitrogen flow rate was 2sccm, the plasma source power was 400W, and the growth time was 2h.

[0054] (3) Preparation method of InN nano-pillar heterojunction: chemical vapor deposition process is used to deposit the prepared InN nano-pillars in N 2 Annealed at 500 °C for 5 min in a protected selenium atmosphere to obtain InN / In 2 Se 3 Nanopillar heterojunction.

[0055] The Si-based InN nanopillar heterojunction annealed in the sulfur atmosphere of this example is used for photoelectrolysis of water: the prepared Si-based ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com