Polymer electrolyte, preparation method thereof and application of polymer electrolyte in solid-state battery

A solid-state battery and polymer technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, non-aqueous electrolytes, etc., can solve the problems of lithium separation in batteries, easy thermal runaway, and uneven lithium-ion negative electrodes in metal lithium batteries. Effect of improving contact, reducing risk of thermal runaway, and improving interface performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A polymer electrolyte used in batteries is a polymer electrolyte introduced with cyclopentene structure and active hydrogen groups. The polymer electrolyte includes a polymer and an electrolyte, and the cyclopentene structure and active hydrogen groups are located on the main chain of the polymer; the electrolyte includes a salt, and if the battery is a lithium-ion battery, the salt is Lithium salt. By introducing a cyclopentene structure into the polymer structure, the oxidation resistance and toughness of the electrolyte are improved, and the active hydrogen-containing functional group is introduced into the polymer structure, which can react with metal lithium to form a good interface in the lithium metal battery. It can react with lithium to form a compound of lithium when it is not uniform and the lithium precipitation occurs in the battery cell, which improves the interface stability.

[0033] As a further preferred embodiment, the raw material of the polymer ele...

Embodiment 2

[0048] A method for preparing a polymer electrolyte, comprising uniformly mixing a cyclopentene structural monomer, an active hydrogen structural monomer, a crosslinking agent, an initiator and an electrolyte, soaking, heating, and in-situ polymerization and then curing to obtain an in-situ cured electrolyte . The soaking time is 18~30h, such as 20h, 22.5h, 25h, etc.; the temperature during soaking is room temperature, usually 10~40℃, such as 25℃, 30℃, 35℃, etc.; the heating temperature is 50~ 100°C, such as 50°C, 60°C, 75°C, etc.; the heating time is 1-120h, preferably, the heating time is 20-30h, such as 20h, 24h, 30h, etc. The heating process is to solidify the polymer electrolyte in-situ. If other initiators are selected, other methods are used to solidify the polymer electrolyte in-situ, and the same effect as this embodiment can also be achieved.

[0049] The mass ratio of the cyclopentene structural monomer, the active hydrogen structural monomer, the crosslinking agen...

Embodiment 3

[0051] A solid-state battery includes a protective plate and an in-situ cured cell, wherein the in-situ cured cell comprises the polymer electrolyte described in Embodiment 1. The in-situ solidified cell includes a positive electrode, a negative electrode, a separator and the in-situ solidified electrolyte.

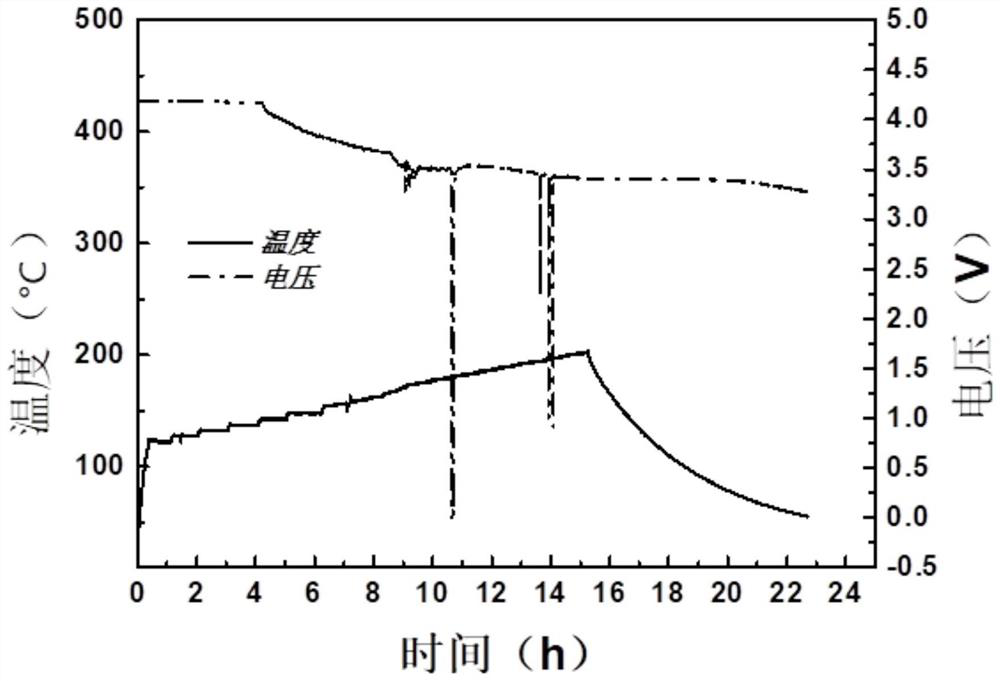

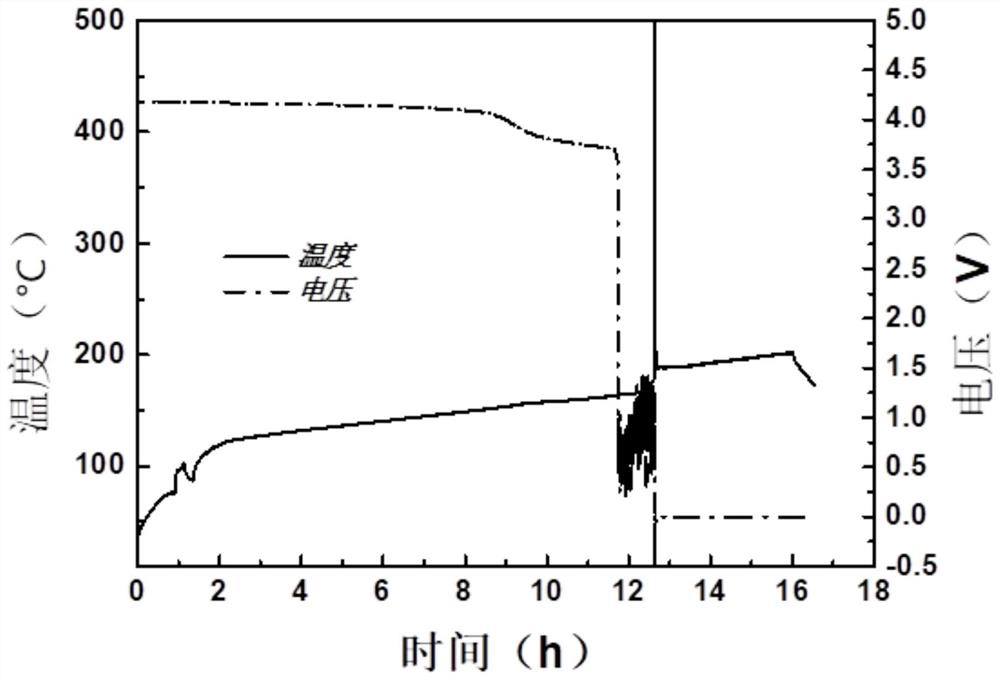

[0052] Experimental group 1

[0053] 5g ethylene glycol dicyclopentenyl ether acrylate, 15g acrylamide, 10g polyethylene glycol dimethacrylate, 0.3g azobisisobutyronitrile, 70g electrolyte (EC / EMC / DEC=1: 1:1 1M LiPF6) was evenly mixed, injected into the soft-packed cells assembled by NCM811 / Li, soaked at 25 °C for 24 h, and then placed in a 60 °C oven to heat and cure for 24 h to prepare an in-situ curing cell.

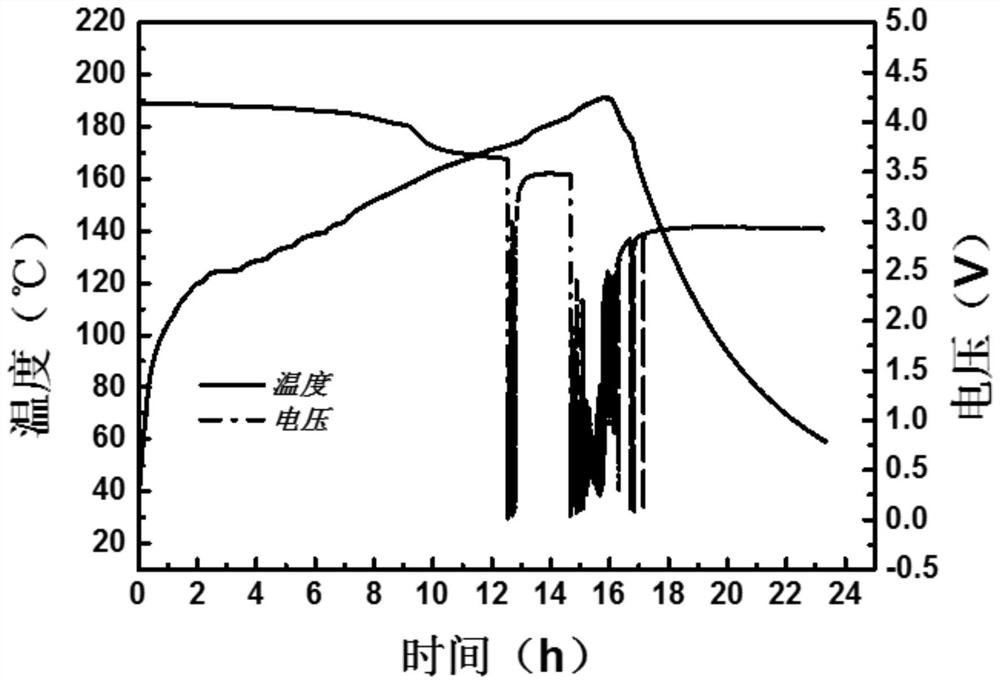

[0054] Experimental group 2

[0055] 10g cyclopentene, 10g dicyclopentene, 15g 2-hydroxyethyl methacrylate, 3g polyethylene glycol acrylate, 5g ethoxylated trihydroxymethyl propane triacrylate, 0.3g azo Diisobutyronitrile and 70g of electrolyte (EC / EMC / DEC=1:1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com