Halogen-free flame-retardant master batch for glass fiber reinforced nylon as well as preparation method and application of halogen-free flame-retardant master batch

A flame-retardant masterbatch and nylon technology, applied in the field of halogen-free flame-retardant masterbatch, can solve the problems of affecting the bonding effect of glass fiber and nylon resin, difficult to control the usage of glass fiber, and short length of glass fiber, etc., to achieve large porosity, The effect of reducing addition and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

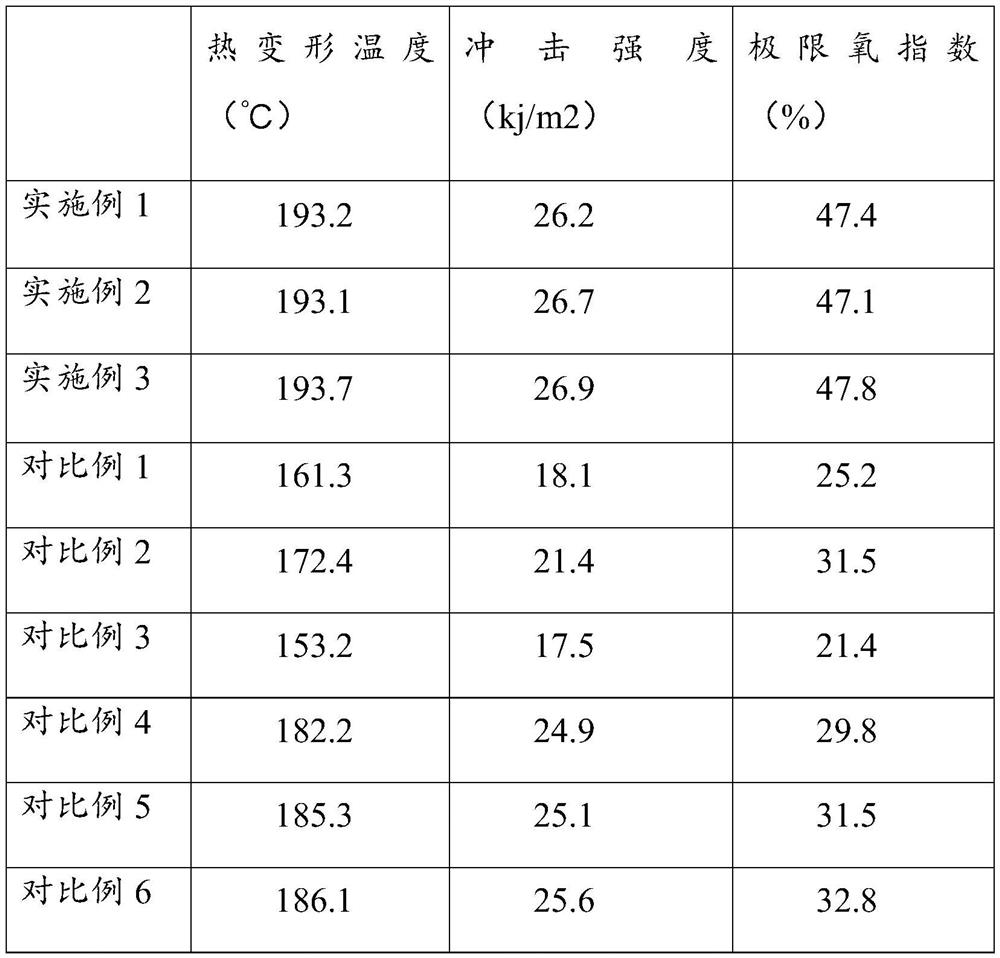

Examples

preparation example Construction

[0039] The preparation method of the interface guide agent is as follows:

[0040] S1: Put the bentonite into a hydrochloric acid solution with a mass fraction of 1-5% and soak it for 10-20min. drying to obtain active bentonite;

[0041] S2: add active bentonite to 2-3 times the mass fraction of 10% lanthanum chloride rare earth solution, then add 1-5% nonylphenol polyoxyethylene ether, 1-2% tetrabutyl titanate, 1-1.5% of isoeugenol, then add 10-20% of total active bentonite friction modifier, react at 70-80 ℃ temperature for 15-25min, the reaction speed is 500-1000r / min, the reaction is over, to obtain friction modified loaded bentonite;

[0042] S3: The friction-modified loaded bentonite is sent into 2-3 times of silane coupling agent KH560 for stirring and dispersing treatment. The stirring and dispersing time is 20-30min, and the stirring speed is 100-1000r / min. After stirring, wash with water and dry. , the interface director is obtained.

[0043] The halogen-free fla...

Embodiment 1

[0061] The halogen-free flame retardant masterbatch for glass fiber reinforced nylon of the present embodiment includes the following raw materials in parts by weight:

[0062] 40 parts of nylon 6, 10 parts of glass fiber, 4 parts of interface guide agent, 5 parts of graphene carrier, 6 parts of shell powder flame retardant, 1 part of lubricant;

[0063] The preparation method of the interface guide agent is as follows:

[0064] S1: put the bentonite into a hydrochloric acid solution with a mass fraction of 1% and soak it for 10 min, the soaking temperature is 45°C, and ultrasonically treated with 100W ultrasonic wave for 5 min.

[0065] S2: Add active bentonite to 2 times the mass fraction of 10% lanthanum chloride rare earth solution, then add 1% nonylphenol polyoxyethylene ether, 1% tetrabutyl titanate, 1% isoeugenol , and then add a friction modifier of 10% of the total active bentonite, react at a temperature of 70 ° C for 15 min, the reaction speed is 500 r / min, the rea...

Embodiment 2

[0083] The halogen-free flame retardant masterbatch for glass fiber reinforced nylon of the present embodiment includes the following raw materials in parts by weight:

[0084] 50 parts of nylon 6, 20 parts of glass fiber, 10 parts of interface guide agent, 11 parts of graphene carrier, 10 parts of shell powder flame retardant, 3 parts of lubricant;

[0085] The preparation method of the interface guide agent is as follows:

[0086] S1: put the bentonite into a hydrochloric acid solution with a mass fraction of 5% and soak for 20 minutes, the soaking temperature is 55 ° C, and ultrasonic waves of 300W are used for ultrasonic treatment, and the treatment is completed for 10 minutes. After the treatment, wash and dry to obtain active bentonite;

[0087] S2: Add active bentonite to 10% lanthanum chloride rare earth solution by 3 times, then add 5% nonylphenol polyoxyethylene ether, 2% tetrabutyl titanate, 1.5% isoeugenol , and then add a friction modifier with a total amount of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com