Preparation method and application of flame retardant DDSP

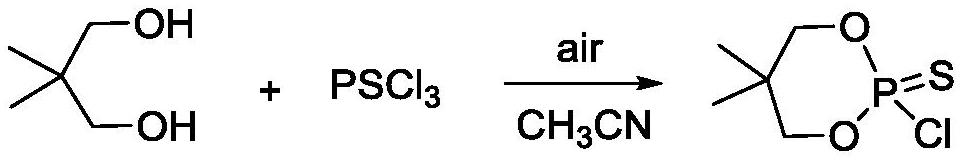

A flame retardant and reaction technology, used in the field of preparing DDSP without acid binding agent, can solve the problems of explosion, danger to construction personnel and users, and achieve the effects of high reaction efficiency, stable properties and high phosphorus content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing DDSP, comprising the following experimental steps:

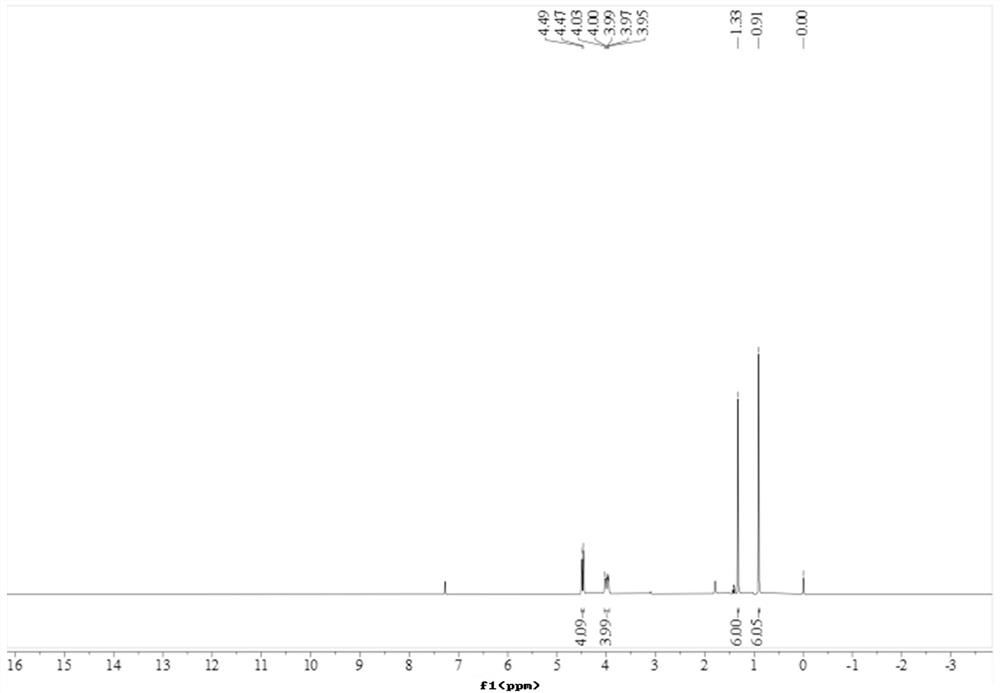

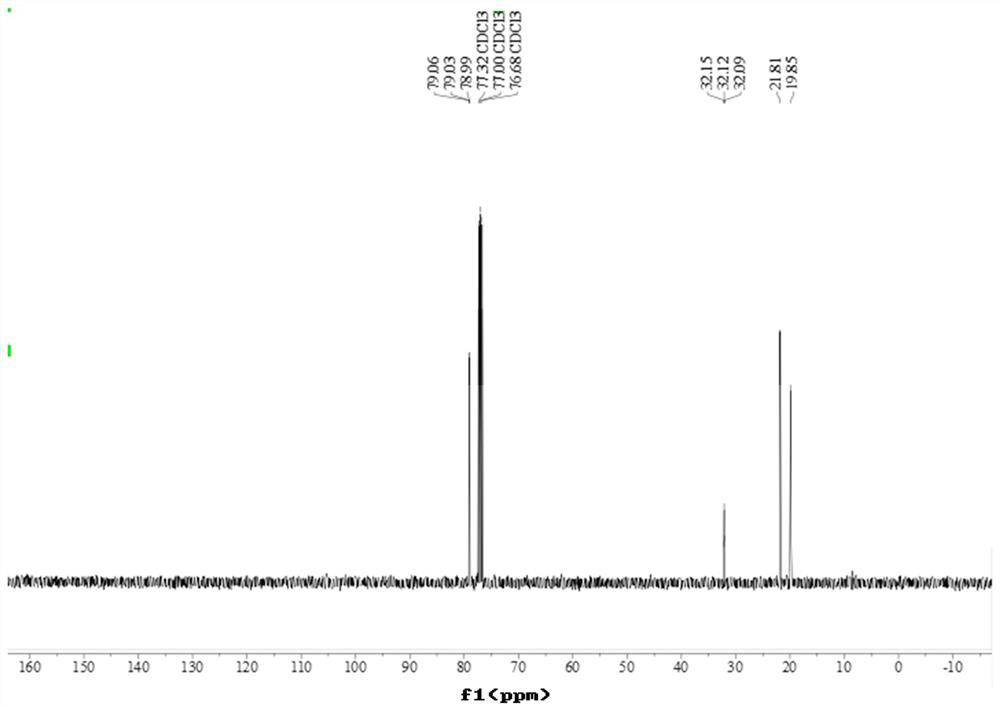

[0029] Weigh 20mg (0.2mmol) of neopentyl glycol in a 50ml double-neck flask, add 0.2ml of acetonitrile solvent, add 33mg (0.2mmol) of trichloride to the double-neck flask, and use an air pump with an exhaust volume of 30L / min Air was introduced into the double-necked flask, heated at 25°C under the condition of condensation and reflux to dissolve, mechanically stirred for 1 hour, after the reaction was completed, acetonitrile was removed under reduced pressure, washed with deionized water, filtered and dried to obtain the target compound 39 mg, 98% yield.

[0030]

Embodiment 2

[0032] A method for preparing DDSP, a gram-level experiment, comprises the following experimental steps:

[0033] Weigh 1.04g (10mmol) of neopentyl glycol into a 50ml double-neck flask, add 5ml of acetonitrile solvent, add 1.53g (10mmol) of phosphorous trichloride into the double-neck flask, and heat it at 25°C under the condition of condensation and reflux. Dissolve, use an air pump with a displacement of 30L / min to introduce air into the double-necked flask, stir mechanically for 1h, after the reaction is completed, remove acetonitrile under reduced pressure, and wash with deionized water, filter, and dry to obtain the target compound 1.85 g, 92.5% yield.

Embodiment 3

[0035] A method for preparing DDSP, the reaction under nitrogen gas is introduced, comprising the following experimental steps:

[0036] Weigh 1.04g (10mmol) of neopentyl glycol into a 50ml double-neck flask, add 5ml of acetonitrile solvent, add 1.53g (10mmol) of phosphorous trichloride into the double-neck flask, and heat it at 25°C under the condition of condensation and reflux. Dissolve, use a nitrogen bottle with an exhaust volume of 30L / min to introduce nitrogen into the double-necked bottle, stir mechanically for 1h, after the reaction is completed, remove acetonitrile under reduced pressure, and wash with deionized water, filter, and dry to obtain the target compound 1.81 g, 90.5% yield.

[0037]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap